Bartlett graduates Dilara Temel and Lachlan Fahy have created TerraCool, a proposal developed to combat the growing problem of urban heat through evaporative cooling. Its recessed ceramic elements manipulate porous material properties to cool air through evaporation. The use of ceramic vessels for evaporative cooling has been widely documented. TerraCool examines to update of this ancient method for enhanced cooling performance through innovations in advanced geometry.

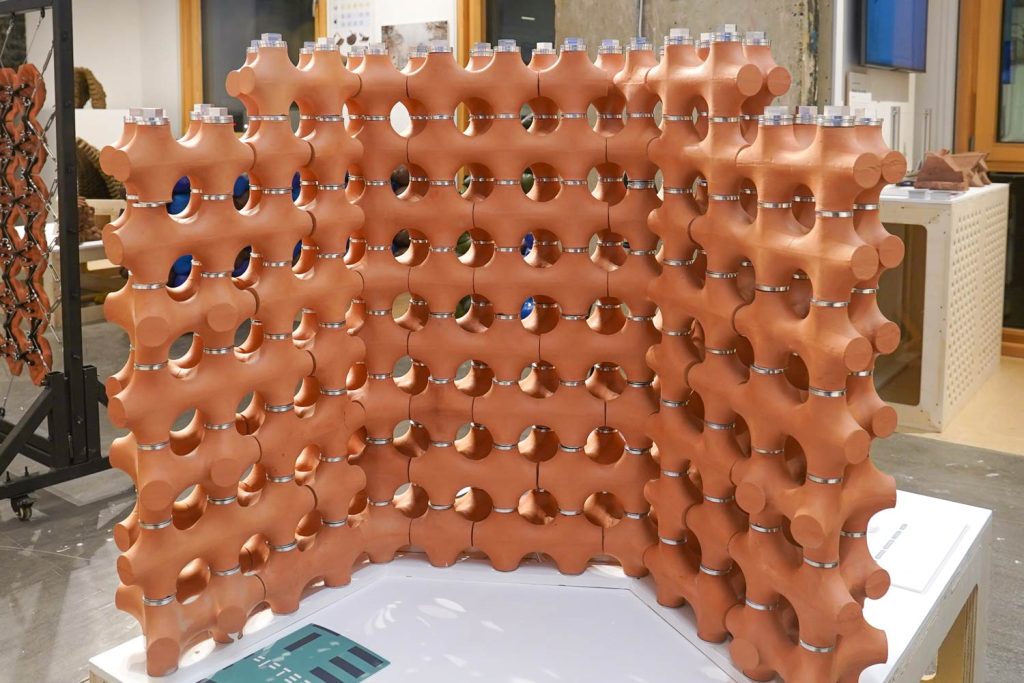

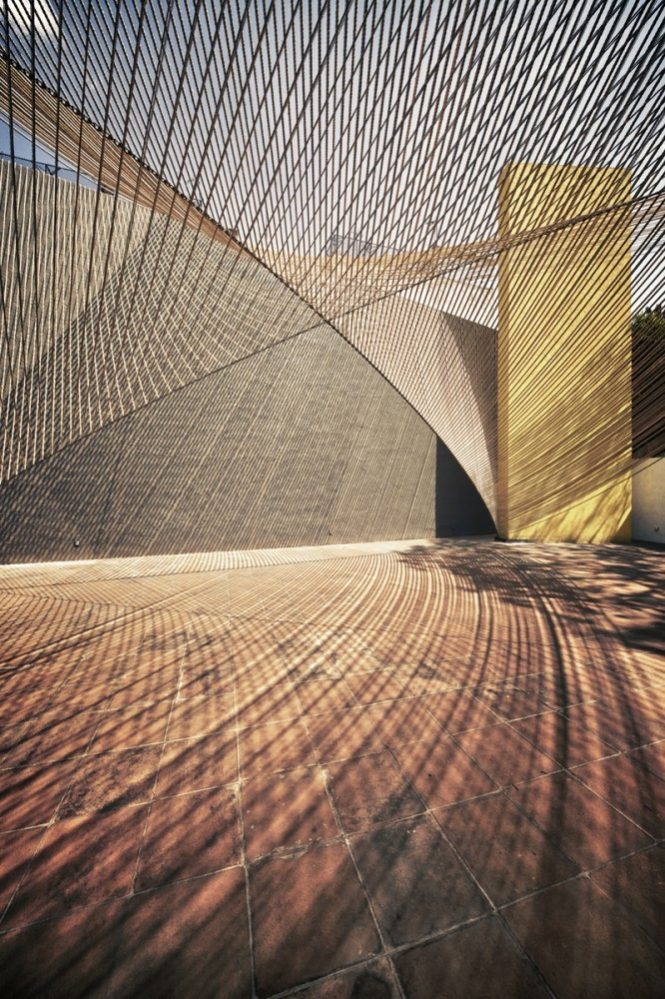

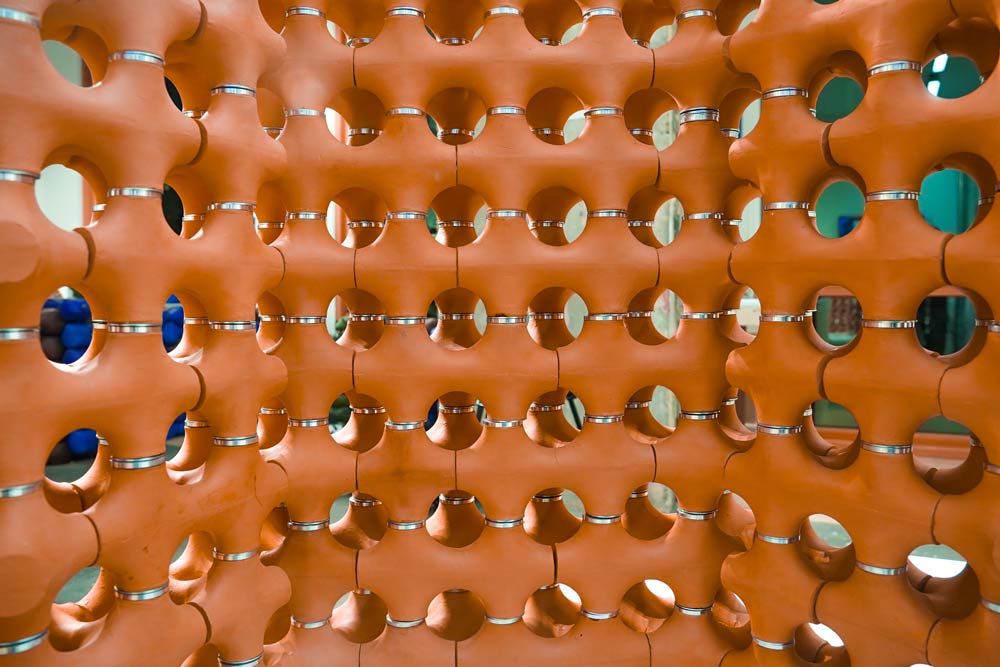

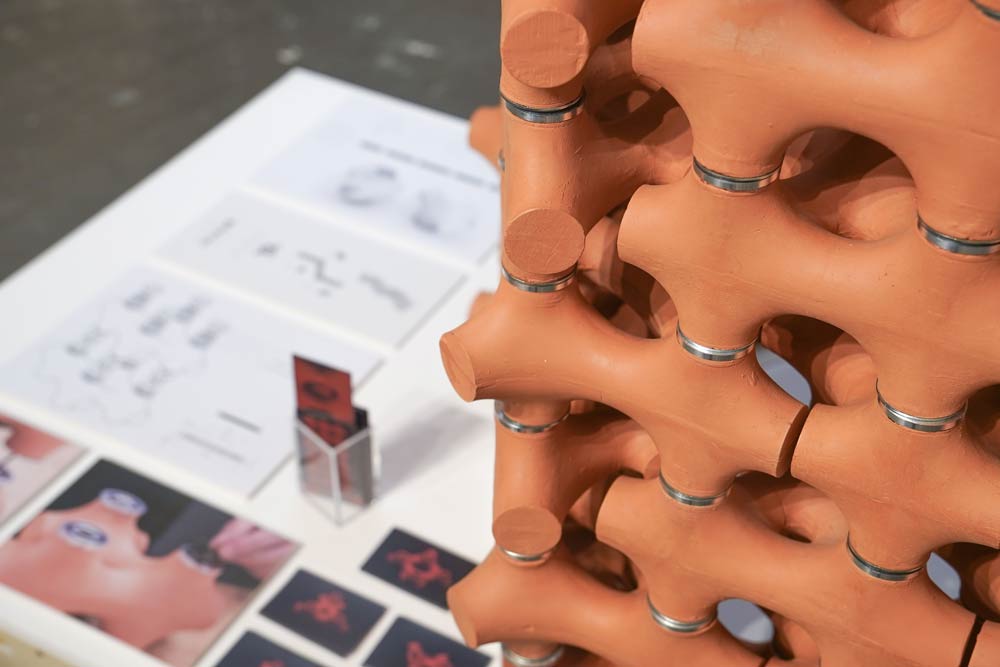

The project aims to facilitate the architectural integration of evaporative cooling through its modularity, parametric adaptability, and ease of manufacture. A demonstration of the system was shown at the Bartlett FIFTEEN show in the form of a terracotta cooling screen.

In recent years, the effects of extreme heat on human health and comfort have become profound. Today, most people living in cities face the “urban heat island” phenomenon. Urban heat islands are a consequence of the rising temperature of trapped warm air caused by city elements such as buildings, roads, and vehicles. For some facilities, the energy needed for cooling seems to be more than that required for heating. This robotic process further perpetuates the problem of urban heat islands by depositing more heat into cities. This need has led them to propose a passive cooling system for making cool places in urban environments. Ceramics offers a high potential as a cooling method, given its historical precedence, affordability, and accessibility.

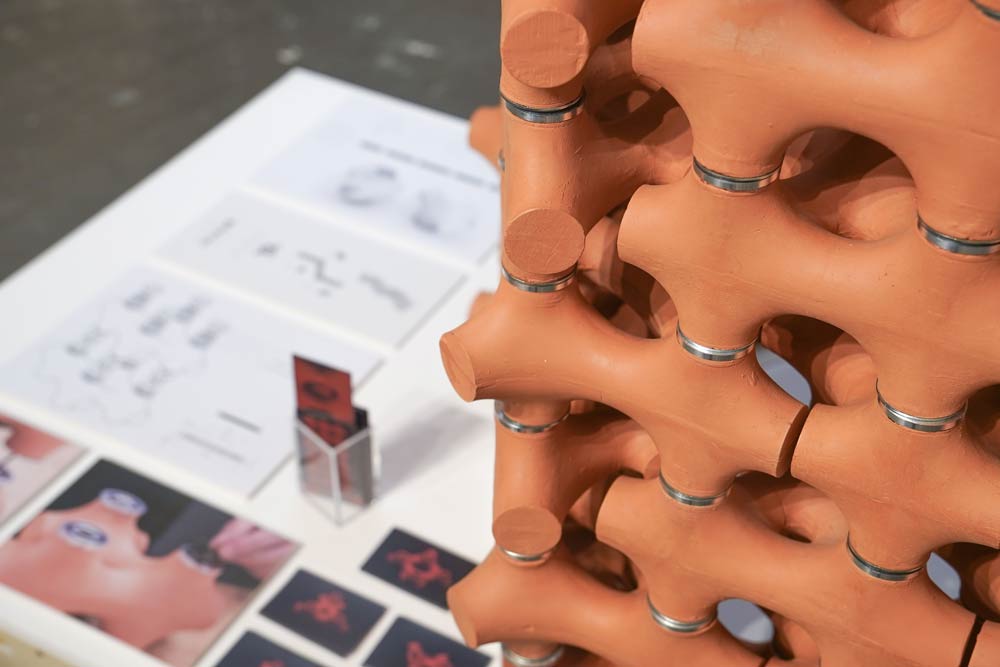

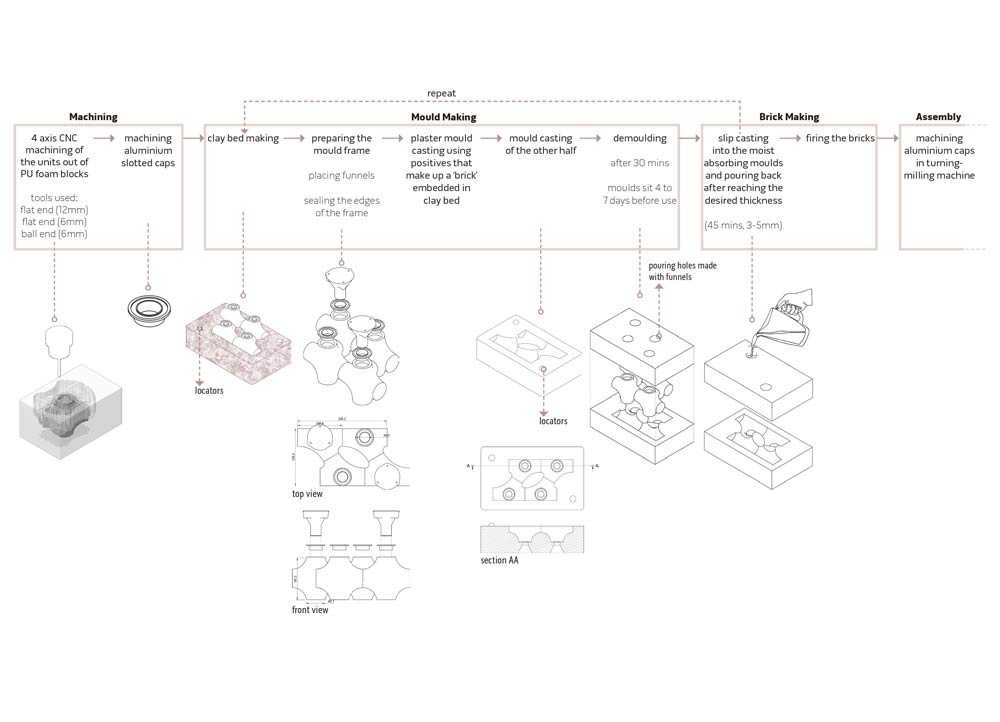

This project contributes towards advancing ceramic evaporative cooling through two critical aspects. The innovations are through optimized surface geometry and a modular manufacturing system. By pairing a parametric script and modular mold system, TerraCool qualifies for the mass customization and manufacture of ceramic cooling systems. In addition, the manufacturing method of slip casting utilizes widely available materials, ensuring a low barrier to access for its production.

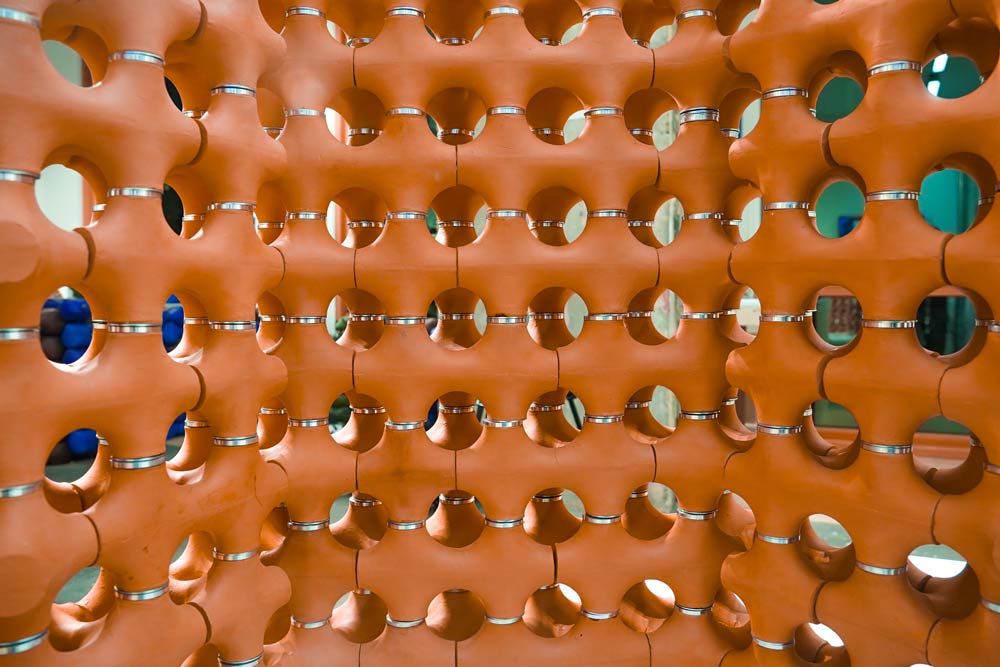

The existing body of research on the performance of ceramic evaporative cooling has established the critical role of surface area on cooling outcomes. TerraCool is the first such system to make the optimization of surface area a defining principle in its design. Furthermore, it is the first attempt to design and manufacture ceramic elements that exploit minimal surface geometries’ potential.

The geometry of TerraCool was designed to feature hollow geometry with the highest possible ratio of surface area to internal volume. This authorizes the communication between the ceramic surface and air. The logic of triply periodic minimal surfaces inspired the geometry. This logic was influenced by research in advanced heat exchangers for power plants. The geometric conditions of the heat exchangers are similar as they require separate, interpenetrating channels with a high volume-to-surface area ratio. Also, the smooth geometry allows flows to move freely without resistance. Aerodynamic shapes have been shown to enhance evaporation in ceramic evaporators. Minimal surfaces also exhibit high structural integrity. This is important to TerraCool, as the geometry must be self-supporting and able to hold its weight as well as the weight of the water it contains.

The other feature which differentiates the TerraCool is its adjustability and parametricity. The goal was to create a parametric system instead of a single repeated component. The bricks that make up the system are generated via a Grasshopper from input parameters. These inputs create curves stitched together to form the surfaces that make up individual units. These units can be modularly combined to form the desired geometry of an individual brick which is then used as the positive to produce a mold. By reusing the units in multiple brick variations, less fabrication is required.

Pairing a parametric script with the manufacturing method implies limitless variations of form and application. If applied as envisioned system would be parametrically adjusted in the design phase to suit the needs of different designs and projects. The invention comprises a parametric model that can be easily altered and customized to generate geometries for fabrication through subtractive and additive methods.

An additional goal of its parametricity is also to allow adjustments based on climatic and location-based variations to allow designs to be adapted to best suit the climate and available water sources. Other use cases may even take advantage of the geometric properties of hollow high surface area geometries, enabling further innovation and broader adoption. However, this ease of use also has potential risks of misuse, as it may allow the manufacturing of designs that do not consider crucial factors of the local climate.

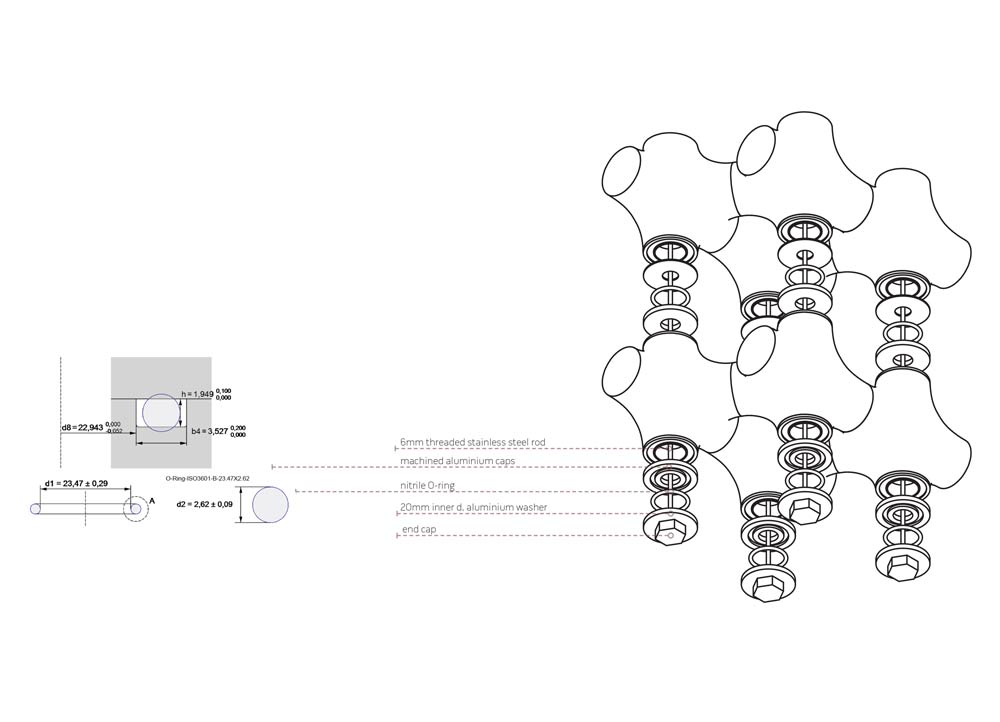

The connection between brick elements is achieved using O-rings and threaded rods, which pass through holes in the elements. Threaded caps at the tops and bottoms are screwed tightly to provide compressive force between bricks. This squeezes the O rings between the mating faces forming a watertight seal. The structure can be easily disassembled for redeployment or maintenance.

The ceramic elements stack in a staggered formation similar to traditional bricklaying. This securely joins the structure horizontally and horizontally and allows water fed at the top of the structure to flow throughout the whole system. The sealed system provides moisture for evaporation without exposing the contained water to the air. This lowers the chance of microbiological contamination and health risks commonly associated with alternative evaporative cooling methods.

One of the application proposals is TerraCool Urban Oasis, a deployment of the bricks in an urban pocket where the environmental conditions can be controlled. The system can briefly be described as placing TerraCool in cavities to create urban oases. It aims to be the main component of refuge spaces in the city that welcome people like an oasis in a desert. It uses purified grey water collected from neighboring buildings’ water systems. The site where the proposed design is placed is enclosed by buildings from three sides and blocked by an entrance screen on the fourth side, so the cooling loss is inhibited.

As a pair, the actual evaporator and the entrance screen create still, cool air in the urban pocket park. Thereby it serves almost as a step-well or a summer room. Operational energy is acquired from photovoltaic panels on top of the entrance screen, the least shaded area—obtained solar energy to pump and control the amount of water by sensors.