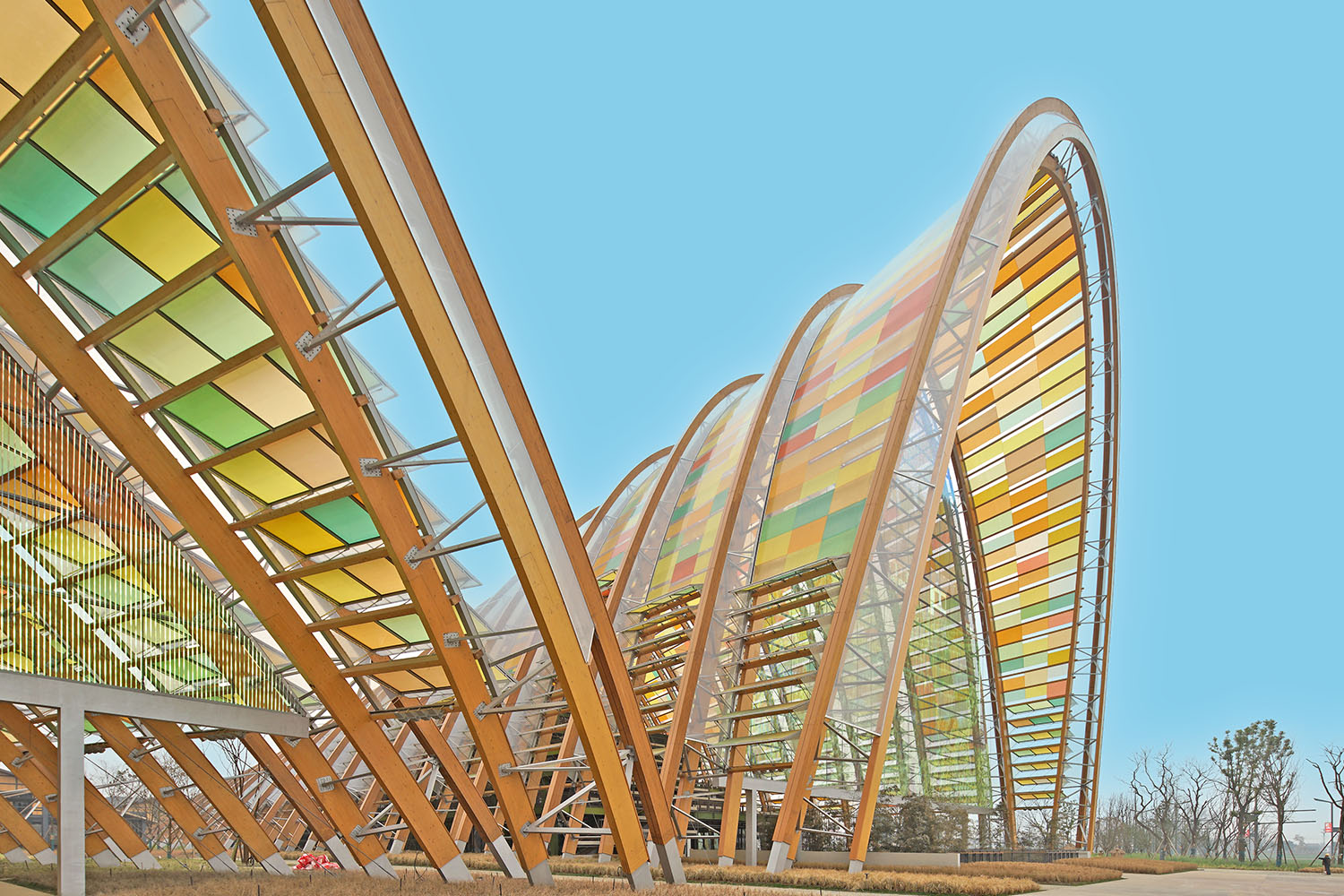

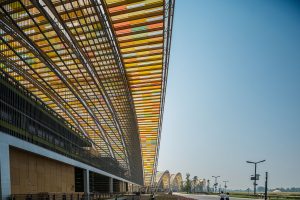

The Tianfu Agricultural Expo is part of a major development program in Chengdu’s greater metropolitan area, which aims to compete with China‘s other major economic hubs. The wide views of waving rice fields and mountain peaks on the horizon inspired the architect Cui Kai with the concept for the curved timber enclosures located on the west border of the Sichuan Basin, where up to 5000m high mountains meet Sichuan’s great plains.

The new Tianfu Agriculture Exposition, at over 75,000 square meters, is Asia’s largest timber structure and one of the world’s largest timber structures. This vault series (G1-G5) employs unique Vierendeel-inspired trusses, a hybrid of timber chords and steel webbing, to achieve clear spans of up to 110m and heights of up to 44m.

Tianfu Agriculture Exposition ensemble’s unique wave blends gently into the landscape, but it also challenges the engineering team to materialize the architectural scheme into a bold project on a very tight schedule. The roofs of these halls are clad with ETFE. Still, they are open-ended, encouraging a direct connection with the surrounding farmland and housing museums and displaying agricultural products from the region.

The result is a one-of-a-kind series of long-span timber structures built in a year and a half by team members from three continents, fulfilling the owner’s desire to showcase the economic power of the Chengdu agrarian region and provide a world-class attraction through innovative engineering and design.

Structural Engineering

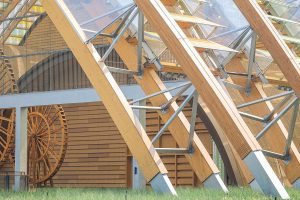

The concept of a “expanding” arch with varying triangular cross-sections emerged during early design discussions. Each cross-section is made up of two single bottom chords and a double top chord, with a deeper, wider truss near the bottom. This design’s triangular push-pull nature is structurally more efficient than a bending-active Vierendeel web.

Each arch’s diagonal webbing is structurally designed to allow for slender web elements that almost disappear and minimize the visual connection between top and bottom truss chords. Because the Larch double top chord is exposed to the elements, well-planned weather protection and flashing concept are required throughout Tianfu Agriculture Exposition. Glulam purlins support the pre-tensioned exterior ETFE weather membranes against the two neighboring arches on top of the truss bottom chords.

The structural system of all vaults is the same, consisting of independent truss arches joined laterally by purlins and global cable bracing. The purlins transfer vertical and local orthogonal wind forces to the bottom chords, where they are translated into axial and bending chord forces. The steel base connections transfer chord forces into the massive concrete foundations designed by the local design institute via steel embed plates.

The same structural system, with significant geometrical variation, is used in all five buildings. Because of this, it is ideal for automation and parametric generation. The structural model center lines were generated concurrently with the geometry exploration in the main Grasshopper script, allowing for direct model export for structural analysis.

Fabrication

The project’s assembly line nature played a special role in efficient, detailed design. In this case, efficiency was a delicate balance between material cost savings and easy-to-install repetitive connections to ensure a smooth preassembly process.

Because the glulam pieces had to be shipped by rail from Europe to China, single members were limited by container sizes. The parametric project tools were used in this case to optimize container packing and shipping sequence.

Temporary fabrication facilities took over once the material arrived on site to assemble the so-called sub-assemblies. These 11.5m long assemblies were made up of un-spliced glulam chords and steel webbing. The up to 35m and 25t heavy lift assemblies were formed by connecting two to four sub-assemblies near the final arch location. Each arch is made up of up to five lift assemblies.

Installation

The superstructures were built after all internal steel buildings were completed to ensure crane access below. After experimenting with various erection methods, it was discovered that the shoring towers could be supported by steel structures below where necessary. The surveyed shoring towers not only provided temporary support but also played an important role in the construction process by controlling the arch geometry.

Each arch erection started with the base lift assemblies, supported by a shoring tower at the tip. During this phase, the base connections were temporarily fixed to the foundation embed plates.

After a sequence of arches were erected and tied together by purlins, most shoring towers could be lowered and reused for the next arches. Finally, after vault completion, the LED screen cables were installed and pre-tensioned in specified load steps and order.

Project Info

Architect: Cui Kai / China Architecture Research & Design Group

Engineer: Structure Craf

Project Size: 800,000 sf.

Clear Span, Height: Up to 110m (360’), up to 44m (144′)

Location: Chengdu, China

Status: Completed 2021