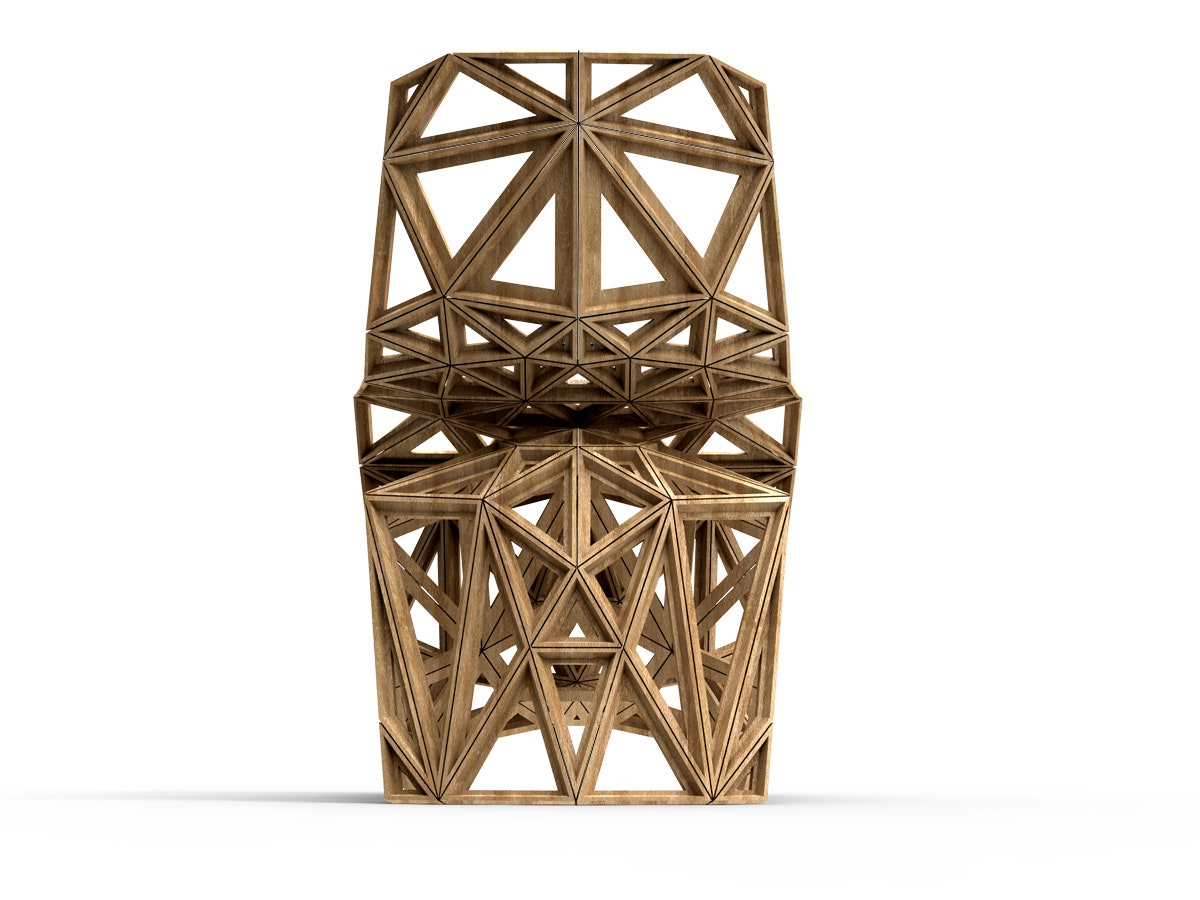

How cool is a chair that you can piece in like solving a puzzle! The Dutch designer Joris Laarman creates symbiotic 3D printed chairs ‘mimicking human bones’ in his studio. His philosophies intermix classic design and science that outgrows to weave a much efficient and evolved mechanism in aesthetic brilliance.

His exhibition gallery, Bits and Crafts, much like his Bone Chair, the new works presented have a quasi-craftsmanship aesthetic to it, as if tangling an affair between a carpenter and a computer scientist. The main attraction of the show, the Maker Chair revels as Laarman’s most ambitious one. Designed to perform a puzzling act, sculpted in algorithms, reminiscing Verner Panton’s 1960’s injection-moulded chair, this newly entwined creation celebrates as a mathematical imagination.

Every single element is made from ABS plastic that tongue and groove to form a whole. One chair requires 77 pieces of lego material, snapping in unison to absolute sturdiness, and you can make it in less than $30 (black and white version). “It doesn’t have any glue and you can sit on it” says Laarman. Another exciting piece at the exhibition is made from 300 CNC-milled walnut pieces glued by epoxy to a perfectly smooth geometric pattern. There are many variations in milled resin and oak, and another in aluminium that binds in unison.

Laarman believes in democratizing design, being an open-source design to make it available in the online market. He has a website to download the blueprints, which can be used to fabricate your own in a matter of 10 days. He followed the advent from the early 20th century, where modernist designers published their blueprints and manuals. “I don’t think in the future people will actually make their own chairs if it’s not super simple,” he says. “But these are simple.”

Designer Joris Laarman liked to question, how can we push the boundaries of digital fabrication forward? And he said, we start by thinking, how we can make something relevant, to experiment what’s possible with the technology right now, and maybe just beyond what’s possible.”

Laarman employed two full-time researchers at his lab in Amsterdam, to play around with digital fabrication techniques that do not exist yet. Leading to discoveries like the MX3D-Metal Printer, a robotic arm connected to a MIG welding machine that prints metals like steel, aluminium, bronze and copper. MX3D mesmerizes, like watching black snake fireworks expand. “We’ve gotten a lot of interest from construction companies and shipyards,” says Laarman. This new way of fabrication could eventually disrupt the traditional design systems. This is the future, stated Laarman. For now, it is best expressed through art. “This is definitely an experiment; we’re still in the process of figuring out what’s going to work.”