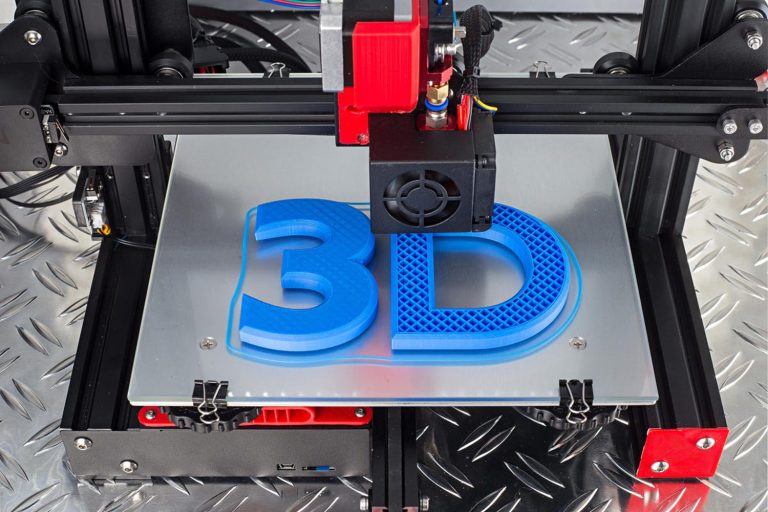

No, we’re not talking about your office’s inkjet printer, we’re talking about 3D printing. 3D printing is no longer confined to specialized labs and industry exhibitions. These days, the breakthrough technology has become a cornerstone of many manufacturing processes the world over.

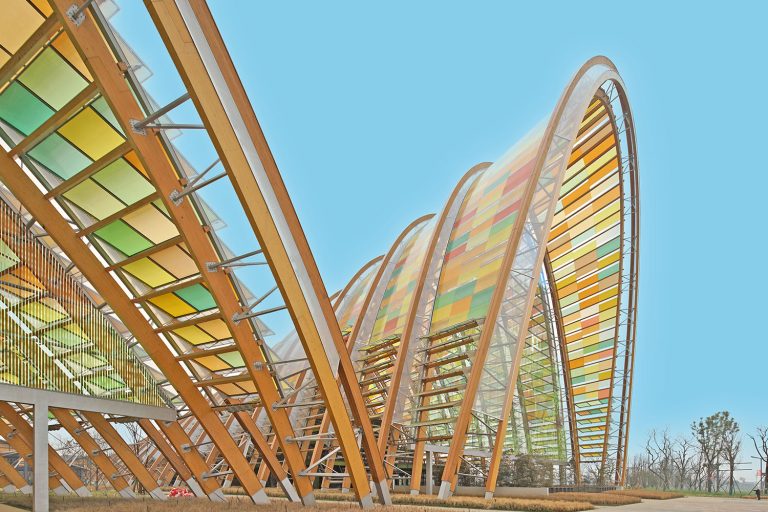

It would be a stretch to claim that 3D-printed structures and goods have made their way into our day-to-day lives quite yet. Your house probably wasn’t printed out in layers by a giant 3D printing robot. Yet, there are people living and working in 3D-printed buildings, and it’s likely that construction will become more and more reliant on technology as time passes.

Understanding 3D Printing in Construction

When we think about construction, we think about bricks and mortar, poured concrete, and metal girders. Essentially, we think of large-scale building projects, multiple homes built on huge plots of land, or towering office blocks. This image contrasts with our idea of printing. Particularly when you consider that the average person’s experience of printing is limited to a home printer or that lumpy machine in the corner of the office that is forever breaking down. 3D printing, of course, is a world apart.

Even for someone with an idea of how 3D printing works, it’s hard to imagine the machine that could actually do the job. It sounds like something that might be useful by the time we have emigrated to Mars, but not a practical solution to anything in the here and now.

The truth is, 3D printing homes at this scale is not a fantasy; it’s happening now.

Automated Homebuilders

There are start-up companies that are already being commissioned to build homes using mobile robots that print out walls and partitions at a much faster pace than can be achieved by a team of laborers. These machines move around what will become the perimeter of a building and print the walls in layers, and may only require a single human operator.

And that’s one way in which we can understand 3D printing’s role within the construction industry- as automated homebuilders. This is obviously a radical change for the building industry, though with much of the world crying out for new homes, it may be a welcome one.

So why is the building project down the street still heavily populated with hardworking bricklayers and not relentlessly efficient printing machines? Well, this is not yet a technology that has been adopted at scale, though like any emerging technology that works, it is likely only a matter of time.

In the meantime though, more homes and commercial buildings are relying on 3D printers for more specific, small-scale solutions.

Customized Building Components

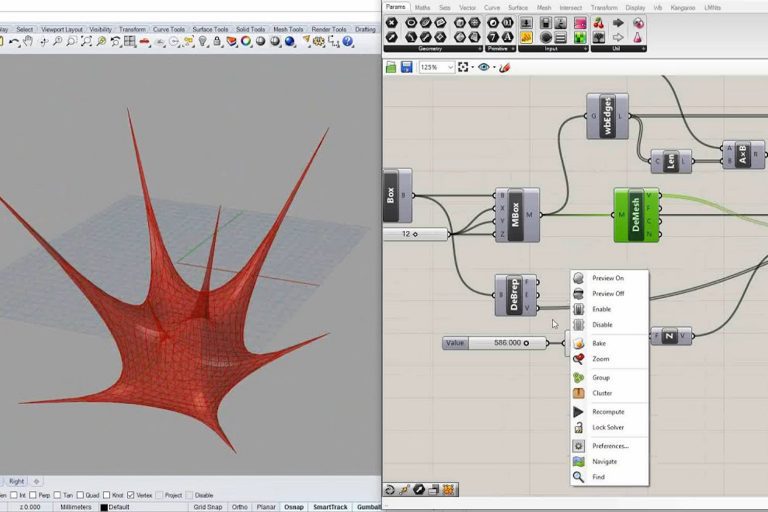

3D printers can quickly print a custom component for a building project. The practical applications of this simple truth are incredibly widespread. In the past, architects and builders needed to rely purely on what building materials were available on the market. Of course, it was possible to commission manufacturers to build products to spec, but this comes with additional time, money, and hassle costs.

With 3D printing technology, it’s possible to print materials to spec without consulting a manufacturer. This has the potential to speed up the design, manufacturing and construction processes considerably. Particularly as designers can adapt an already proven 3d printer model that can be purchased via a 3D model shop. Of course, 3D printing is still a growing practice, yet as it becomes more widespread, builders and architects will begin relying on the tech more and more. Not least because prices and associated costs will decrease.

Benefits of 3D Printing in the Construction Industry

Time Reduction: Projects completed in significantly shorter timeframes compared to traditional construction methods. Enables swift project turnaround, enhancing agility and responsiveness to project demands.

Cost-Effectiveness and Sustainability: Minimizes material wastage through precise material allocation, thereby enhancing sustainability. Reduces overall construction costs by optimizing material usage and minimizing resource wastage.

Enhanced Safety: Mitigates the risk of accidents and injuries on construction sites by reducing manual labor and automating processes. Promotes a safer working environment for construction workers by minimizing hazardous tasks.

Downsides of 3D Printing in Construction Industry

Initial Investment Costs: This is the big one. Right now, there is just not the infrastructure in place for large scale 3D printer manufacturing.

Even if you do want to get going with 3D printing, you may need to overcome a substantial initial investment cost.

Limited Material Selection: There is a limited amount of approved or practical 3D printed materials. Resin 3D models are a common 3D model, but this might not be suited to all construction needs.

Human Cost: From an implementation point-of-view, there is a potential human cost to introducing 3D printing at scale. Any implementation at 3D scale has to be properly costed, including the human cost of retraining and the like.

Using 3D Models for Customized Building Components

Some of the criticisms leveled at those that are pushing for more 3D printing in construction include:

- The process is too slow

- The components are untested

- It’s too expensive

At a glance, you can see how each of these objections could be easily overcome with time. The process will speed up, the components will prove their worth and the costs will lessen. In the meantime, designers can speed up the process and buy tried and tested 3D models for printing online. These can then be adapted and integrated into the construction project’s design files.

Architects and construction professionals can easily procure 3D models tailored to their project needs, whether through the purchase of pre-made designs or the commissioning of custom models. This streamlined process not only saves time but also enables efficient utilization of resources, allowing for the swift realization of innovative and complex architectural visions.

3D Printing: Making Construction Agile

The adoption of 3D printing in construction marks a pivotal shift towards a more agile and efficient industry. As technology continues to evolve and adoption rates increase, we can expect to witness a surge in innovative construction practices in the coming years. With ongoing advancements in materials science, printing technology, and regulatory frameworks, 3D printing holds the potential to revolutionize the way we build, offering unprecedented speed, precision, and sustainability. Embracing this transformative technology opens doors to endless possibilities, paving the way for a future where construction is faster, safer, and more adaptable to the evolving needs of society.