Today, robotic applications are being used in the realms of architecture, construction, and research. with the paradigm shift within architecture, digitalization and computational logic has become integrated into the field. As a means of more digital practices, robots present a lot of opportunities for us. Robots are physical, efficient, and very precise machines that co-occupy our spaces and produce high-quality products by doing repetitive tasks.

We can currently create entirely new building systems and processes with these robots. By using these tools in more creative ways, new methods of design, making, and approaching our practices as architects can be achieved. The main point is the way architects and designers bring these technology leveraging processes into the real architecture world. As there are various means of robotic approaches within architecture, we compiled a list of top architectural fields where robots can be used.

1- Building Construction

Due to the scarcity of skilled labor, growth in the number of projects, and a need to limit the environmental effect, automation and robotic applications are integrated into the building construction to boost productivity, cut costs, and reduce waste.

A: Landesgartenschau Exhibition Hall

The first time industrial robotic applications were employed in a large-scale, permanent structure was at Landesgartenschau, an exhibition hall at the ICD at the University of Stuttgart, which Achim Menges directed. The project was a collaboration between Müllerblaustein Holzbau GmbH, the Institute for Computational Design (ICD), the Institute of Building Structures and Structural Design (ITKE), and the Institute of Engineering Geodesy (IIGS). The Landesgartenschau benefits from a computational agent-based framework that treats each type of plate as an agent and tries to establish a good middle ground between fabricability and robotic reachability. The project is an architectural prototype of contemporary breakthroughs in lightweight timber construction, computational design, and robotic fabrication. The building is the first to have its basic structure entirely built of robotically prefabricated beech plywood plates.

B: Robot Science Museum

Designed by Melike Alt?n???k Architects, the Robot Science Museum will not only exhibit robots, but also robots will be in control of all the phases of the museum, from design to construction. The whole building will be constructed with robotic applications and drones. The curved, circular structure of the building’s metal facade incorporates robotically constructed and reused Expanded Polystyrene (EPS) mold to shape the slab into arches and give the building its curving form. Robots will mold, weld, assemble, and polish the structure’s components. They will 3D-print the museum’s concrete landscape. Moreover, drones will be used to map out building sites, examine them, and operate construction equipment.

2- Architectural structures

Architectural structures, made of linear, standard and non-standard, regular and irregular, and complex typologies are among the subjects with a lot of promise in design for robotic fabrication.

A: Tongji university bridge

Tongji university bridge is a robot fabricated hybrid, sturdy bridge that is constructed by combining two methods of large-scale metal 3D printing and filament winding. Constructed in the 2019 summer workshop at Tongji University, the bridge is made of thin carbon fibers winding over a 3D-printed metal frame. The skeleton steel basis of the bridge was built via 3D printing, while the web-like stairs and railings were made by twisting carbon and glass fibers. As these hybrid processes do not require any formwork or mold, these approaches save money, material, and energy compared to traditional construction methods like subtractive manufacturing or cast pouring.

B: Concrete Stereoform slab

The Concrete Stereoform slab by SOM is built using robotic fabrication methods. The project intends to lower the carbon footprint of concrete without requiring significant modifications in building processes. A robotically produced and reusable Expanded Polystyrene (EPS) mold was used to shape the slab into arches to create the structure’s curving form. Therefore, the amount of material consumed and waste generated to create the structure’s curving form is reduced. As an environmentally friendly method that minimizes its carbon footprint, this approach uses 20% less concrete than traditional techniques and has a 20% lower cost.

3- Pavilions

Robotic fabrication can offer a lot of possibilities for creating a direct link between the infinite possibilities of the digital world and the material world. As flexible, open space structures with multiple functions, pavilions offer a great potential to benefit from robotic architecture.

A: Pavilion based on sea-urchin shells

This research pavilion showcases robotic textile fabrication techniques for segmented wood shells, completed by the University of Stuttgart’s Institute for Computational Design (ICD) and Institute of Building Structures and Structural Design (ITKE). This segmented shell is the first of its type to use industrial sewing on a large scale to create wood pieces made up of hollow, molded beech plywood components and to laminate and hold them together. All of these processes have been done by robots. The project draws its morphological inspiration from the structure of sea urchins and sand dollars, both sea-bed invertebrates, to build what looks like a floating beehive.

B: ICD/ITKE Research Pavilion

The ICD/ITKE Research Pavilion, constructed in 2015, illustrates the architectural possibilities of a revolutionary building approach inspired by a water spider’s underwater nest construction. Thanks to the innovative robotic fabrication techniques, an initially flexible pneumatic formwork are gradually strengthened by reinforcing it with carbon fibers from the inside. The design approach for this fiber-reinforced structure is based on biological construction processes research. The resulting lightweight fiber composite shell creates a pavilion with distinctive architectural characteristics while also being a very material-efficient and functionally integrated construction.

4- Space-based constructions

Together with humans’ desire to colonize the Moon and Mars, there is an increasing need to build actual buildings and structures on this planet. However, it is much more rational to benefit from robotic architecture in such severe conditions. Robots are our tools to be combined with design ideas to help the rapid construction of a lunar colony with initial operational capabilities.

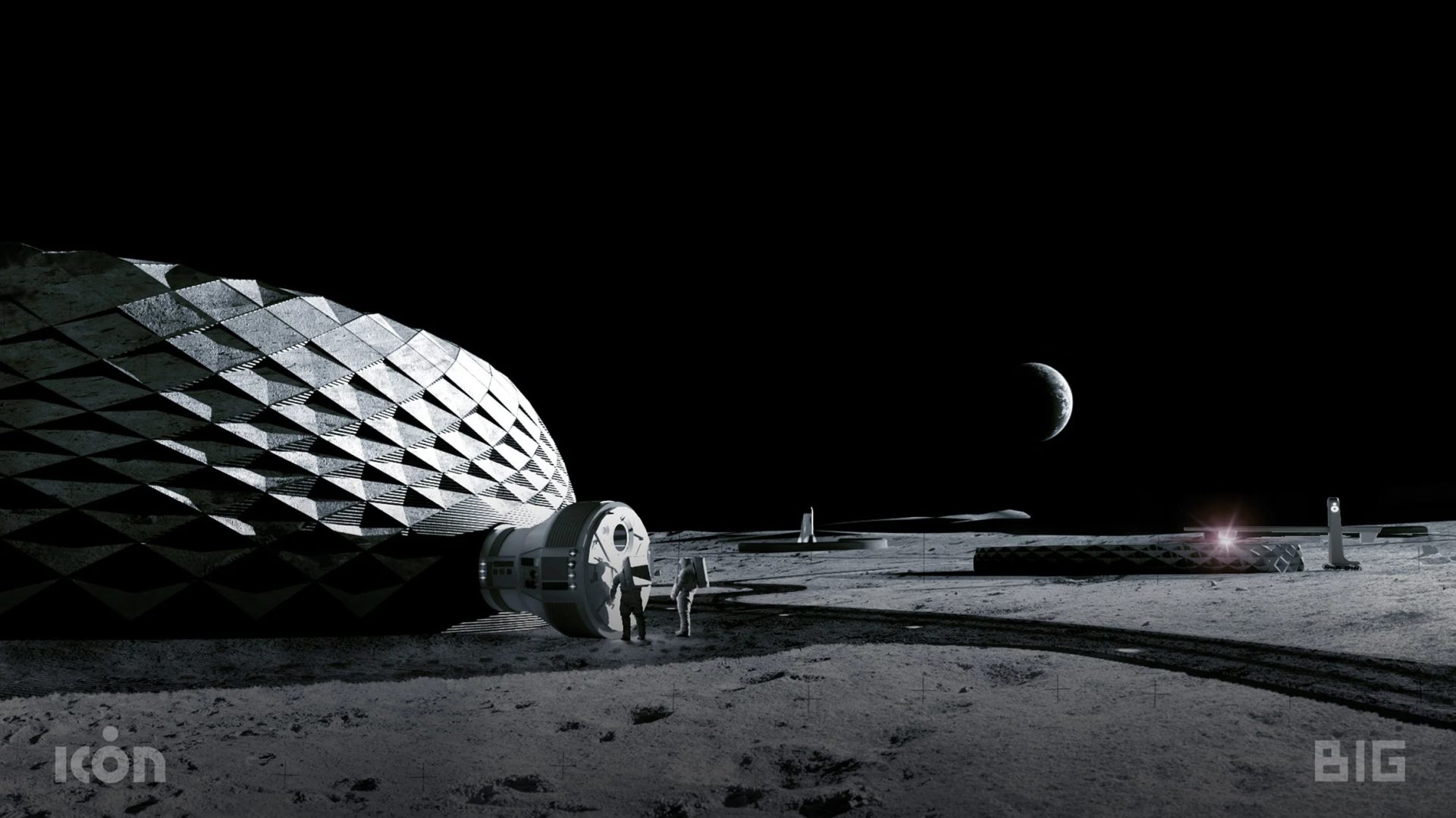

A: Olympus project

Designed by Bjarke Ingels Group, Olympus is an envisioned home for humanity in a distant universe. The project is a space-based building system to support future explorations of the Moon resulting from the collaboration between ICON, the innovative construction technology firm, SEArch, the Space Exploration architecture, and BIG. The project intends to establish a 3D-printed infrastructure for living on the moon utilizing elements present on the moon’s surface.

Indeed, Olympus is a sustainable lunar dwelling that will be the first human entry into extra-terrestrial architecture with sturdy structures that give superior thermal, radiation, and micrometeorite protection than metal or inflatable shelters can offer. The project investigates all of the required components, from landing pads to habitats, to make humans a spacefaring civilization.

5- Robot-made products

As robots are designed to perform fast and precise tasks, when combined with human creativity, they can lead to exceptional possibilities in which constraints are removed.

A: Robot-milled marble vases

Serving as digital, flexible, and precise carvers, robots can create outstanding objects and use technology to transform easily perceivable solid things such as stone into fluid, organic, and light objects. Designed by Layth Mahdi, the illustrated collection is a range of marble vases and curved tables that are milled by robotic applications and developed using algorithms. The artworks have undulating surfaces, and flowing shapes cut using 7-axis robots. The flowing shapes were created during the design stage by overlaying a mix of digital modeling and scripting software.

Conclusion

Currently, digital design and robotic fabrication are advancing into common architectural processes. Robotic architecture is being embraced in all its steps, from design to construction and services. As showcased in the text, robotic architecture covers a wide range of opportunities. As PAACADEMY, we also held a robotic fabrication workshop in which students got familiar with the design for robotic fabrication. It was a hands-on experience incorporating technological topics of robotic fabrication. Click here to watch the recordings of the workshop.

Leave a comment