The Learning Architecture for Learners, created by VUILD, was built as a project of Tokyo Gakugei University’s Educational Incubation Center, or “Explayground,” a Japanese institution that fosters cooperation between business, government, and academia.

CNC-machined wood beams and panels are used as formwork for the concrete slab. The structure is made of reinforced concrete and uses CLT as formwork. The finished surface is called “residual formwork.” According to its designers, this is the first time a concrete formwork has been used as the main structure in Japan.

The finished building, which will be utilized as an open facility where anybody can experience cutting-edge manufacturing technology and construct the appropriate space and place on their own, will also have the CNC machine used to install the formwork.

Design Process

Creating an open area that would be both an expanding, unfinished space and a venue for introducing new public education to the next generation was the design challenge. Furthermore, according to the team, an extreme and experimental architecture was needed, which also served as a learning tool.

As a result, VUILD made the decision to use a 5-axis CNC milling machine to construct a vast, flexible area. In order to maximize the overall shape and convenience of the cut-out, several simulations were run with the restriction of cutting off CLT panels up to 240 mm thick.

Unit Construction Method

In order to build a strong shell, the phase of the amplitude of the CLT beams was moved in the cross direction, and their longitudinal section was planned as a sine curve. In terms of form, Learning Architecture for Learners adopted a roof design that resembles the veins of leaves present in the natural world after undergoing numerous investigations. The cross-section was constructed in a zigzag pattern to generate the depth of the shell; the phases of the zigzag cross-section were then shifted into three levels to provide strength. At VUILD’s on-site factory, the three-dimensional CLT panels were divided into units and fastened to the beams.

Metal fittings were used to unite the panels to one another. The Learning Architecture for Learners’ structure developed into beams on the veins and a slab filling the spaces between the veins when concrete was poured into the beams. The concrete slab is barely 8 cm thick, while the wooden beams span a distance of 25 meters. With its great degree of versatility, this construction approach—for which a patent application has been filed under the number JP 2021-042658—was able to cut costs to 60% of those of the standard shell construction method.

By sharing the 3D data for analysis with structural designers, so-called human errors were avoided. A quick process was made possible by the ability to cross-check this data in all areas of structural analysis, design verification, and part production for fabrication.

In order to mill a 963-part formwork, 360 CLT panels had to be machined, which meant that pathways had to be specially designed for 5-axis cutting. In addition, the tilting and rotating characteristics of 5-axis machining required optimization to account for them. A geometric algorithm for free-form surfaces was created by an internal parametric team, and it was capable of producing CAD documents automatically. Reducing the quantity of manual machining required after machining was another goal of the path formation flow design. To cut down on machining expenses, the surfaces in areas concealed by concrete were roughened within suitable tolerances.

Costs were kept down by strategically placing the panels. This goal was quickly attained with the use of an algorithm for automatic panel placement and shape development, and several kinds of CLT boards with a maximum size of 1,350×4,000 mm were manufactured. There were four distinct thicknesses of CLT boards, ranging from 60 to 210 mm, and a three-dimensional schematic was made to show thickness using color coding. This makes it simple to arrange the components in CLT panels of varying thicknesses.

Project Info

Completion Year: 2023

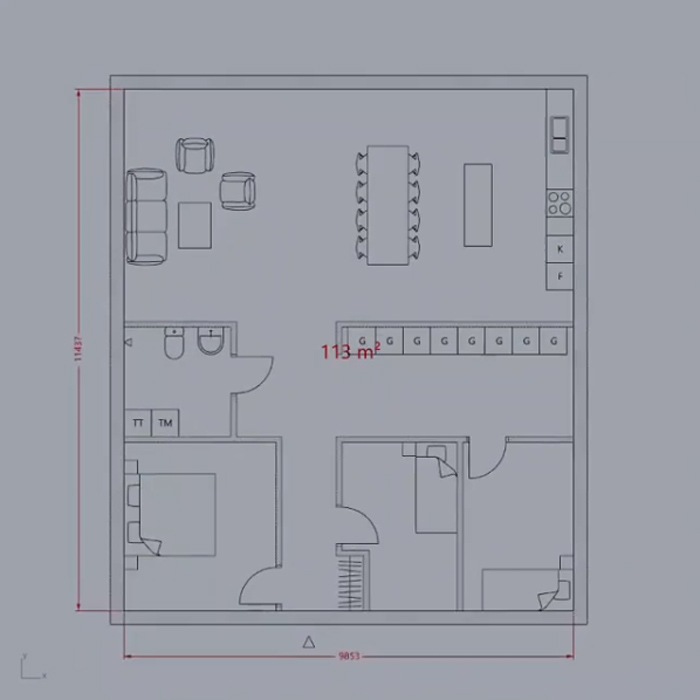

Gross Built Area: 295.90m2

Project Location: Koganei-city, Tokyo

Lead Architects: Koki Akiyoshi

Office Name: VUILD

Office’s Team Design Credits:

Koki Akiyoshi(Designer)

Hiroyuki Nakazawa(Designer)

Gaku Shinohara(Designer)(former staff)

Kenta Isebo(Designer)

Kazuya Takano(Designer)(former staff)

Collaborating Companies Credits:

Jun Sato Structural Engineers(Structural Designer)

Arup(Facility Designer)

Atelier Umi(Construction)

Leave a comment