Imagine a future where construction materials aren’t just used once but are instead part of a continuous cycle, becoming building blocks that live many lives in many forms. And no, this isn’t any science fiction, it’s the groundbreaking work happening right now at the Massachusetts Institute of Technology.

MIT’s development of 3D-printed glass bricks represents a fusion of technology, sustainability, and innovative design. As urban populations grow and the demand for sustainable solutions becomes more pressing, such innovations offer a glimpse into a future where our cities are as dynamic and adaptable as the people who inhabit them. It’s also a revolution in the concept of construction itself. We are talking about actual literal blocks that can be assembled and disassembled like legos.

Circular Construction and Reusable Materials

The construction industry is a massive contributor to carbon emissions, accounting for 38% globally. Fun fact, it has been estimated that every week, we are building a city the size of Paris. I bet right now that percentage is starting to make sense. These emissions are not just coming from the energy consumed during a building’s use but also from its embodied carbon. This term refers to all the greenhouse gasses emitted during the production, transportation, assembly, and eventual demolition of building materials.

A traditional construction process is wasteful and unsustainable. Materials are produced, used, and then discarded or downcycled at the end of a building’s life. Here’s where the concept of circular construction jumps in to save the day. It’s a paradigm shift aiming to minimize waste and maximize the reuse of materials. In this model, the end of one building’s life could seamlessly become the beginning of another’s. Materials aren’t just recycled in the traditional sense; they’re designed from the outset to be reclaimed and repurposed without degradation of quality.

3D-Printed Glass Bricks

Circular construction is being pushed to its fullest potential by a team of engineers at MIT who are developing a new form of masonry. Using advanced technology provided by Evenline, an MIT spinoff, they’ve created 3D-printed glass bricks that aren’t just environmentally friendly but also structurally robust.

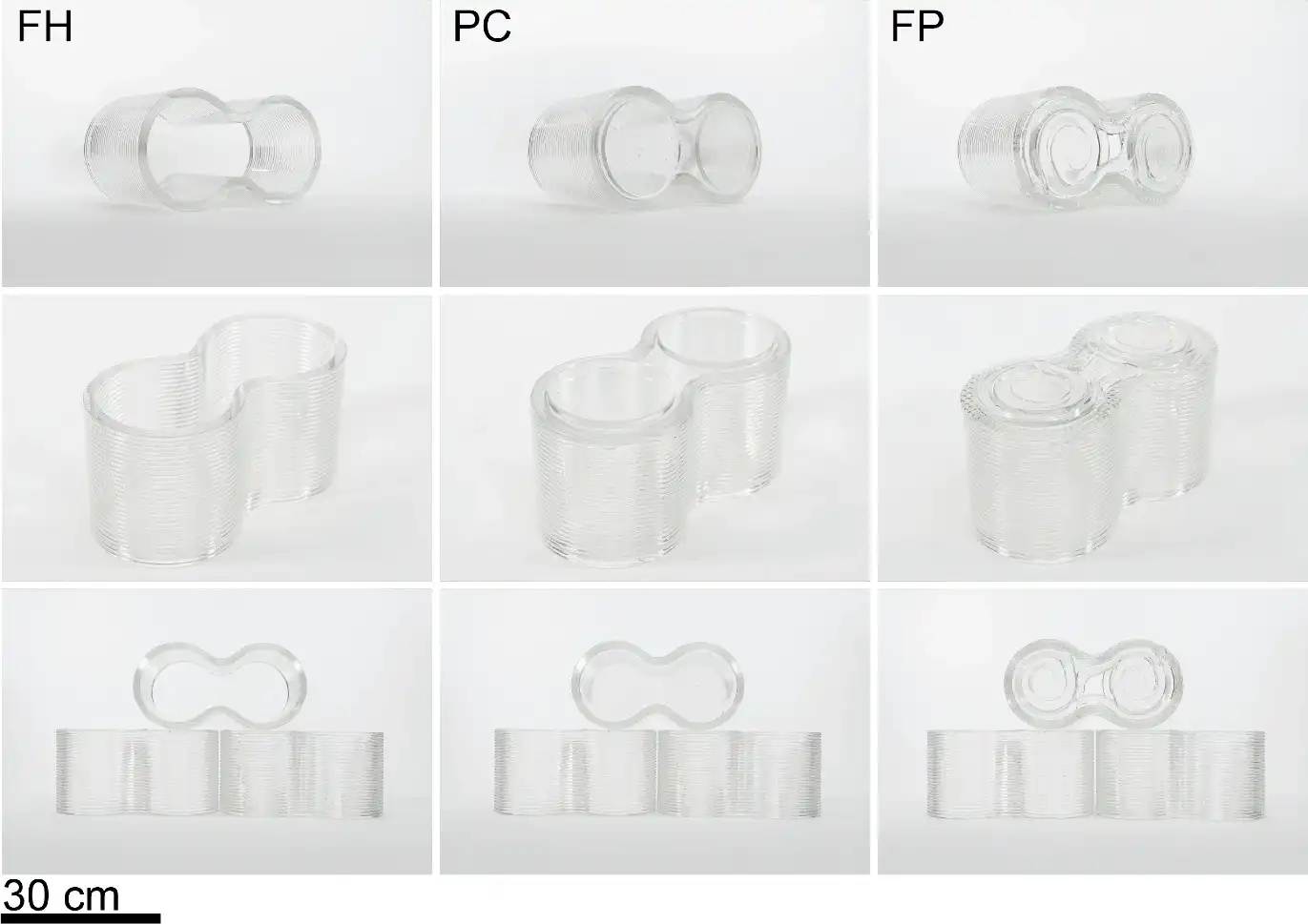

Each brick is crafted in the shape of a figure-eight and designed to interlock with its neighbors, which really sound like LEGO pieces. This design not only ensures stability but opens the door for creative architectural forms, so they won’t limit the creation of curved walls and intricate facades. The punchline goes, during mechanical tests, these glass bricks have demonstrated strength comparable to traditional concrete blocks!

The Brains Behind 3D-Printed Glass Bricks

Kaitlyn Becker and Michael Stern, the engineers leading this innovative project, aren’t newcomers to the world of glass. Their journey began in MIT’s Glass Lab, where they first delved into the art and science of glassblowing as undergraduates. Becker, now an assistant professor of mechanical engineering at MIT, was fascinated by glass’s recyclability and its potential as a sustainable building material.

“Glass is endlessly recyclable as long as it’s kept pure. We wanted to take advantage of this property to create building materials that can be reused indefinitely.” Becker explains.

Stern, founder and director of Evenline, saw an opportunity to push the boundaries of what glass could do. “People don’t usually think of glass as a structural material. We’re challenging that perception and showing that glass can be both beautiful and functional in new ways.” Stern explains further.

How Does it Work?

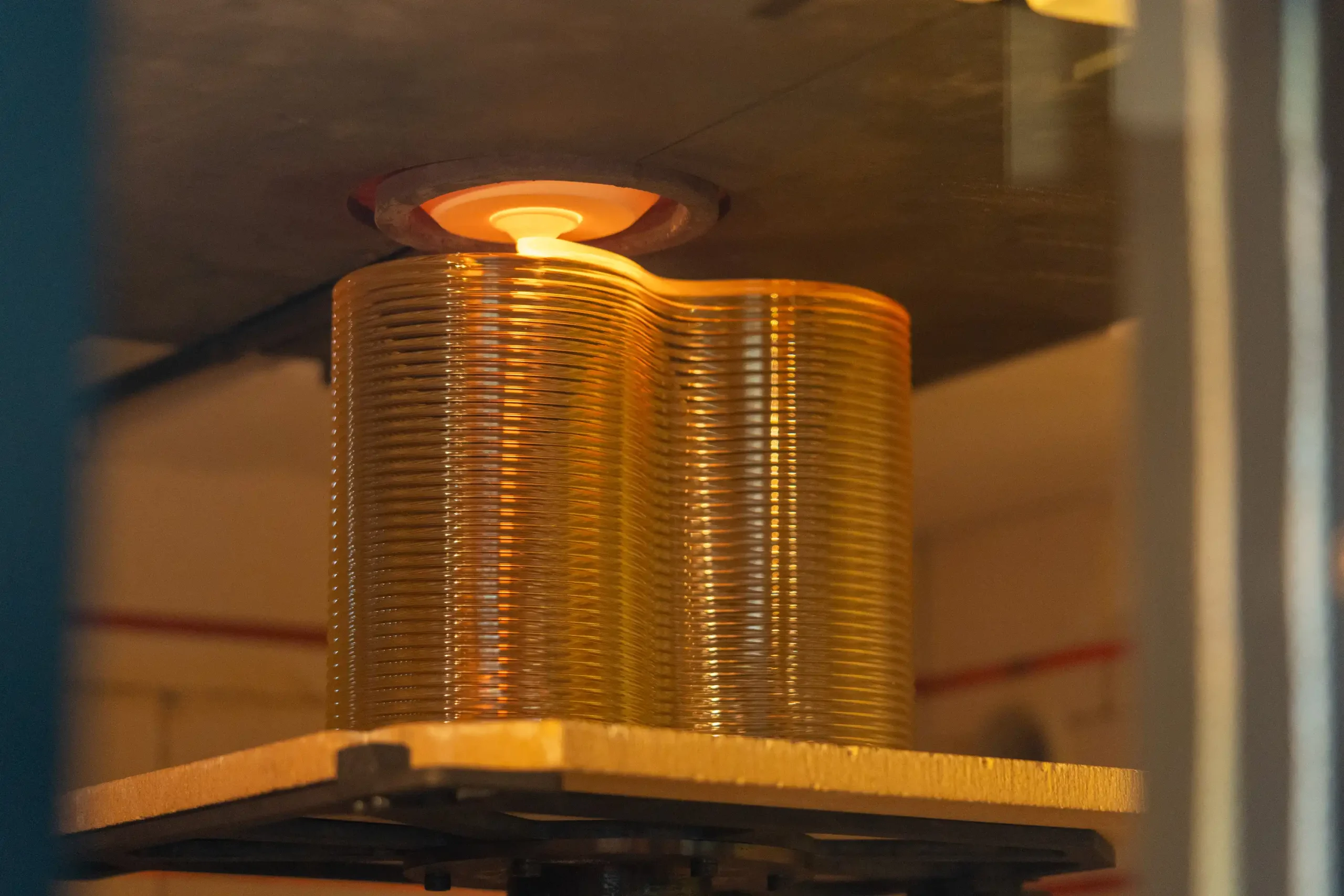

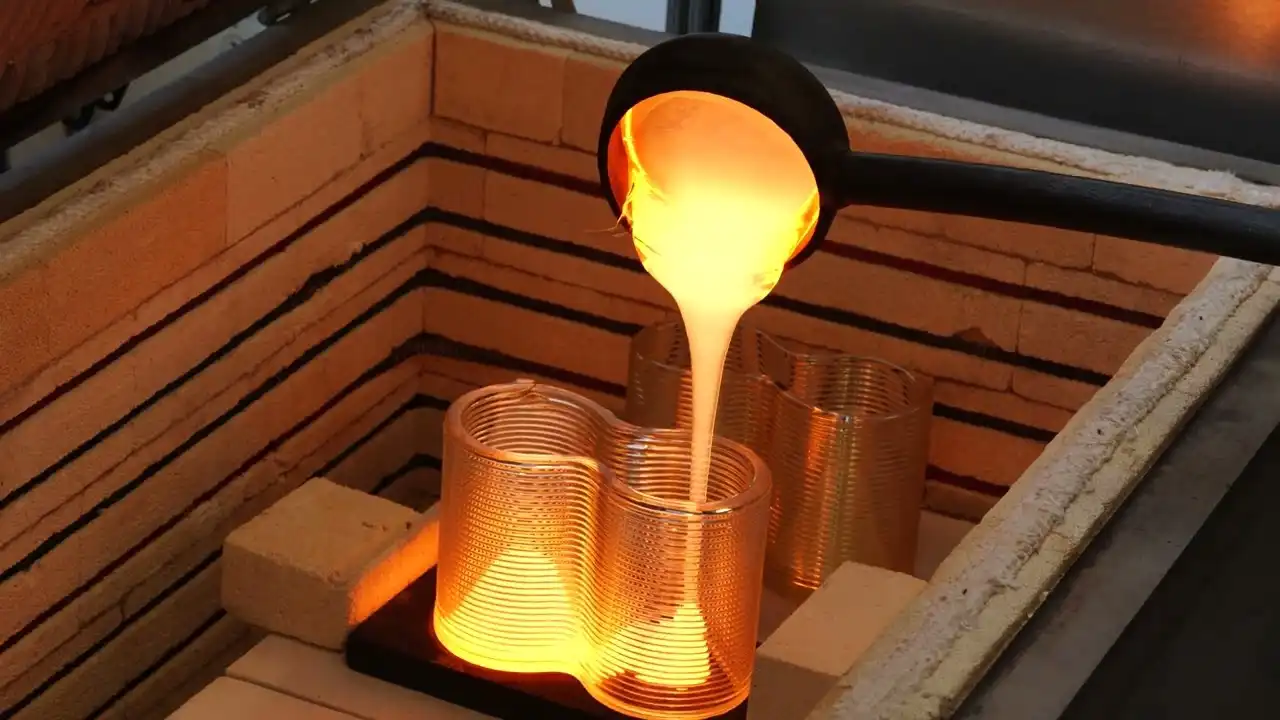

The process starts with crushed glass bottles, which are basically waste materials that would have otherwise ended up in landfills. These are melted down inside a specialized furnace and then fed into the Glass 3D Printer 3 (G3DP3), a cutting-edge device developed by Evenline. The printer models up the molten glass in precise layers, building up the figure-eight-shaped bricks from the ground up. And that’s the beautiful simplicity about technology, who would’ve thought 3D-printed glass bricks can be made so effortlessly?

To enhance interlocking capability, a separately manufactured interlocking feature was attached to the bottom of the brick. This ensures that the glass surfaces remain pristine and the structure can be disassembled without damage. Actually, the mechanism is oddly similar to the studs on a LEGO brick, so the analogy with LEGO is not an exaggeration.

“Glass is a complicated material to work with,” Becker says. “The interlocking elements, made from a different material, showed the most promise at this stage.”

One of the biggest hurdles was ensuring that the glass bricks could withstand the structural demands of building construction. Glass is extremely tricky to work with due to its brittleness and sensitivity. However, the team conducted rigorous mechanical testing using industrial hydraulic presses. The results were impressive – as I’ve already mentioned probably too many times –the bricks held up under pressures comparable to those endured by concrete blocks.

“These aren’t just decorative pieces; they’re structurally sound…The figure-eight shape isn’t just for aesthetics—it distributes stress effectively and allows for the construction of walls with curves and angles,” says Daniel Massimino, a lead researcher on the project.

Environmental and Architectural Impact

Now that the experiment was successful, the team sees immense potential for scaling up this technology. They’re already planning to construct larger structures, starting with pavilions, to demonstrate the versatility and strength of the 3D-printed glass bricks. The ultimate goal is to see these bricks used in real-world buildings and to contribute to a more sustainable and circular construction industry.

“We’re just scratching the surface of what’s possible,” Becker notes. “Imagine a building where every component can be disassembled and reused, not downcycled or discarded. That’s the future we’re working towards.”

This innovation brings us a step further to the hopes of building cleaner in the future. It also isa huge step towards carbon-neutral construction and reducing carbon emissions to create more resilient cities.

Think about how using recycled glass reduces the need for new raw materials and lowers greenhouse gas emissions associated with production. Moreover, the ability to easily assemble and disassemble structures aligns perfectly with the needs of a rapidly changing world. Buildings could be adapted or relocated as required, reducing waste and conserving resources.

Don’t even get me started on the creative architectural side. The transparency and beauty of glass open up new possibilities for design. Can you imagine the poetic aesthetic of buildings that will have continuous glass structures without any interrupting material for support?

Leave a comment