Raphael Ascoli is an architect who studied at McGill University and spent six months at the National University of Singapore as part of his exchange program. He worked as an architect and planner in Tokyo and Shanghai after graduating. In 2017, he founded Blue Temple, an initiative based in Myanmar that focuses on building with local materials and communities. In 2021, he co-founded Housing Now, a project that aims to create prefabricated and modular structural frames using small-diameter bamboo in a collaborative effort with the local community. Additionally, UNICEF Innovation30 has selected Raphael as one of the Young Innovators Shaping the Future in 2023.

“Don’t hesitate to be radical, good ideas are worth pushing to their full potential, an idea is crazy only until it gets built.”

Raphael Ascoli

His journey has been truly inspiring, and we had the opportunity to interview him about his work with locals, bamboo, and his upcoming projects.

Serra Utkum Ikiz (PA): What inspired you to start Blue Temple, and how did your background prepare you for this journey? Can you share a key moment in your career that led you to where you are today?

Raphael Ascoli: After working for a couple of years as an architect in Tokyo, I realized that large-scale development and commercial projects were not gratifying and were contributing to building a world I didn’t agree with. Additionally, the office had toxic management, which led me to an intense burnout. In a couple of days’ time, I quit my job, packed up my stuff and moved to Yangon, Myanmar, this was December 2016. This destination was chosen very spontaneously as I was trying to get out of my situation as quickly as possible.

For a couple of months, I was moving around Yangon, staying in local dormitories and couch surfing. This was about the same time the Rohingya genocide started; the construction industry was shutting down, and the entire country was going down a very dark path. Being declined a job in almost all architecture firms in the city, I decided to start university student workshops to explore the development of community-led public spaces. After a couple of projects, I thought it was time to create a legal entity that would gather these projects together, so I locally registered Blue Temple.

Serra Utkum Ikiz (PA): How is your way across with bamboo and traditional construction methods? Can you please tell us about your experience?

Raphael: Once in Myanmar, bamboo construction very naturally became a topic of interest. Seeing the Shwedagon Pagoda covered with bamboo scaffoldings, I felt compelled to explore this beautiful intangible heritage. One morning, I decided to go the Pagoda’s main office and ask for the contact of their head scaffolder, following up on the connection, I ended up in ShwePyiThar township, sitting at the back of some guy’s motorcycle I met in a local teashop who conveniently knew where the scaffolder was living. This incredible and improbable encounter was eye-opening, he showed me some of the tying techniques he had been using for the past 40 years building bamboo scaffolding.

Something clicked in my brain, and bamboo became some sort of passion or obsession. However, you want to call it. I then met my current business partner, Kyaw Zin Latt, on the Myanmar Bamboo Society Facebook page, he was at that time the main contractor for Habitat for Humanity Myanmar and was building hundreds of bamboo low-cost houses for low-income families living in villages around Bago city, north of Yangon. Having never received any training in bamboo construction, most of what I learned came from KoZin (Kyaw Zin Latt), he was himself a self-taught bamboo builder. We managed to receive a couple of grants from DesignTrust in Hong Kong, which enabled us to build small architectural interventions such as a bamboo playground and a community-led public space.

Serra (PA): As Blue Temple works directly with local communities, how does it affect the design and construction process? Do the communities also participate in the construction process? How does it work?

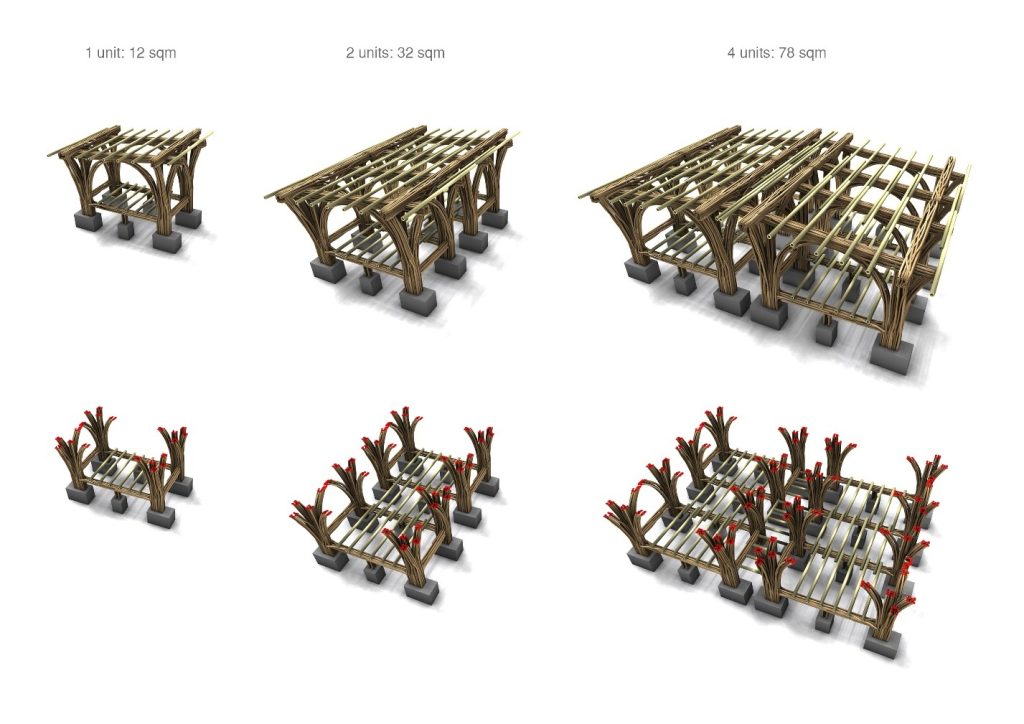

Raphael: Since the February 2021 military coup followed by a nationwide civil war, we decided to focus on low-cost bamboo housing for Internally Displaced People (IDP) and informal settlement dwellers. We developed an innovative construction methodology that combines both the prefabrication of structural housing frames together with a community-participative approach to assembling the frames on-site and building the house.

This participation process starts with a community workshop during which we listen to their needs and wants, they get to decide on the location of the building, the size, the entrances, partition walls, internal circulation, windows, and doors. Once it is all decided, we hire half of the needed labor directly within the community; the other half comes from our trained bamboo construction workers. The community members who take part in the construction are then trained during the building of their own homes and receive a daily wage. This participation is crucial is creating a sense of ownership and home.

Serra (PA): What are the biggest challenges you’ve faced with Blue Temple, and how have you overcome them?

Raphael: The biggest issue in the implementation of our projects is logistical; the current political landscape creates a very complex context in which to operate. Safety and mitigating risks are always a priority. If the site is located in a region where there is active fighting, usually, we wait for a ceasefire agreement to be signed before going there. This is what happened during the construction of the Internally Displaced People (IDP) camp community center built in northern Rakhine State at the border with Bangladesh.

The prefabrication step of the construction makes the process easier to supervise and allows for better quality control, but it also means transporting the structural frames. This transportation is complicated because of the remoteness of construction sites. Accessibility is difficult because the roads are not paved and there are lots of low-hanging electrical cables. To solve this issue, we have built a custom-designed low-bed trailer specifically to transport the structural frames. The trailer is pulled with a 4×4 Hilux; this gives us all the mobility we need to implement projects. Furthermore, whenever the site is very far, we can dismantle the prefabrication kit and reassemble it locally, this greatly simplifies long-distance transportation and reduces the size of the cargo to facilitate the passage through the many military checkpoints along the road.

Serra (PA): How does Blue Temple incorporate modern design technologies and techniques with traditional bamboo construction methods to create these structures?

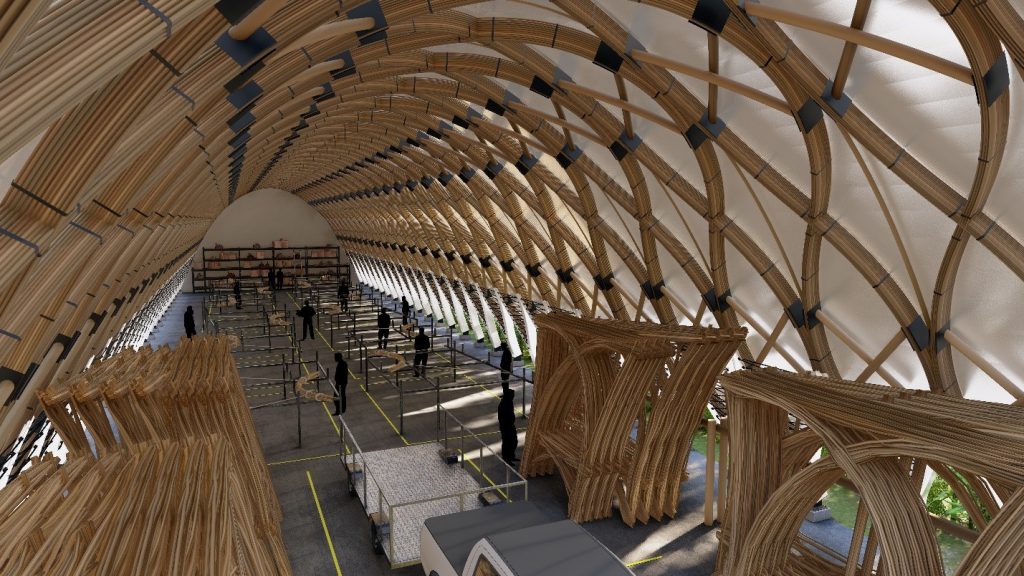

Raphael: Parametrical modeling has always been at the core of our design process. To expand the possibilities of traditional bamboo construction techniques, digital fabrication needs to be designed in a way that is low-tech and affordable. As our company provides both design and construction services, we can follow the project from start to finish. The synergy it creates allows for higher-quality design and construction, both informing each other on how to improve.

Each project is an opportunity to explore a new kind of collaboration between computational design tools and low-tech construction tools. Some of the design tools we have used include topology optimization (Topos) for designing housing with small-diameter bendable bamboo; AR (Twin Built Research) with Hololens for planning complex building footprints before construction; Computational Fluid Dynamics (CFD) for optimizing sediment collection in urban city drains in Yangon; Photogrammetry (ContextCapture) for topography analysis; multi-objective evolutionary tools (Wallacei) for geometry optimization.

Serra (PA): Can you share any upcoming projects or directions for Blue Temple that you’re particularly excited about?

Raphael: We are now trying to scale up the production of our low-cost housing units in Myanmar, to do so we plan to build a 550 m2 bamboo workshop in Bago city where we will be able to prefabricate hundreds of houses a year. This workshop has been designed using the same small-diameter bundled bamboo technique we use for the construction of our houses. It will be a large-scale application of this technology and will showcase the potential this low-cost material can have in the construction industry.

We are already exploring the possibility of exporting this technology to Madagascar in collaboration with Bôndy, a local company specializing in reforestation, to build a workshop within one of their tree nurseries in Tamatave. We are very excited to start building the second 1:1 scale prototype of the workshop soon.

Serra (PA): So, what advice would you give to aspiring architects, designers, or entrepreneurs looking to enter your industry?

Raphael: Don’t hesitate to be radical, good ideas are worth pushing to their full potential, an idea is crazy only until it gets built.

Leave a comment