LOOM, an Adaptable, Wearable, and Flexible 3D Printed Dress by Maria Alejandra Mora-Sanchez

LOOM by Maria Alejandra Mora-Sanchez is an expandable, adaptable, wearable and flexible 3d printed dress that adapts to all body types and body changes. Houston-based designer Maria Alejandra Mora-Sanchez is paving the way for 3D printed textiles with the launch of a new fashion garment in partnership with Cosine Additive.

Mora-Sanchez may be new to the world of 3D printed fashion – the young maker is currently in the midst of an industrial design degree at the University of Houston, alongside an internship at Cosine – but she’s already proven herself as a force to be reckoned with. Her expandable 3D printed dress Loom is already making waves across the textile and additive manufacturing industries, recently securing Mora-Sanchez a Red Dot Design Award | Design Concept 2017.

“I believe that 3D printing is the future of fashion,” says Mora-Sanchez. “With the current developments we are experiencing in this technology there are a great number of opportunities to create amazing new products and materials.” But the industry is lagging: 3D printing has mainly been used for accessories and conceptual sculptural pieces, Mora-Sanchez explains. While fascinating, these developments aren’t functional garments that can be comfortably worn and moved around in.

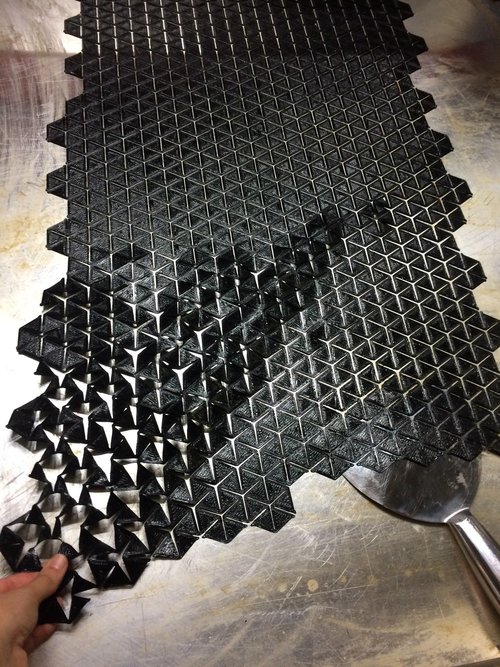

With this as her starting point, Mora-Sanchez devoted her final thesis to creating a truly wearable textile. Pattern-wise, the industrial designer drew inspiration from the Wayuu tribe, an Indigenous community of the Guajira Peninsula in northern Colombia and northwest Venezuela whose textiles are influenced by nature and the tribe’s surrounding environment.

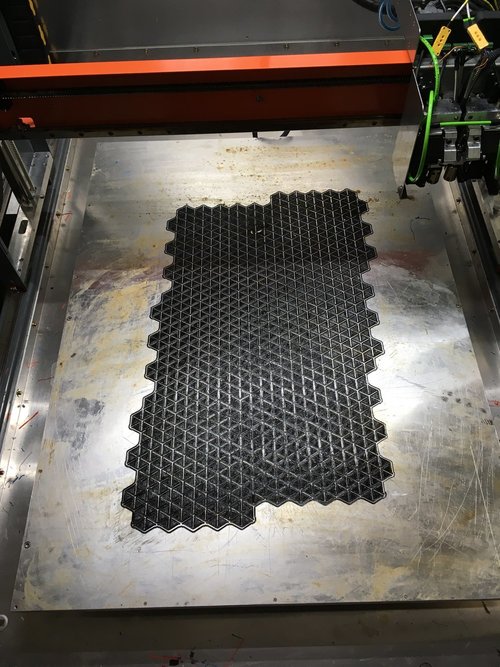

The design process itself was punctuated by experimentation and unorthodox thinking. Mora-Sanchez explains that, although her initial method of fabrication was Selective Laser Sintering (SLS) printing, Fused Filament Fabrication (FFF) eventually proved to be the best route.

Likewise, Mora-Sanchez tested several different materials to observe how her auxetic patterns behaved and interacted, ultimately settling on Thermoplastic Polyurethane (TPU) as her final decision. The Houston designer says this specialized plastic displayed the best combination of high abrasion resistance, low-temperature performance, high elasticity and strength, and the added benefit of resistance to oil and grease. After months of testing, the final garment was printed on Cosine Additive’s AM1 system.

The result is an innovative creation from both a fashion and additive manufacturing perspective. Mora Sanchez’s Loom “combines textiles and additive manufacturing by applying materials and auxetic structures that consider function and the human body.” As an expandable, adaptive, flexible, and above all wearable 3D printed dress, Loom could well represent the future of functional 3D printed textiles. Congratulations to Mora-Sanchez on an outstanding final thesis, and a laudable entry point into 3D printed fashion.

> Via 3ders

Leave a comment