Dassault Systèmes and renowned French designer Patrick Jouin have unveiled Ta. Tamu is a lightweight, foldable, 3D-printed chair that pushes the boundaries of sustainable, material-efficient design. Developed entirely on Dassault Systèmes’ 3DEXPERIENCE platform, Ta. Tamu is a product and a demonstration of what’s possible when generative design, biomimicry, and collaborative virtual tools converge in the name of innovation.

Rethinking the Design Process

Over four years, Jouin’s design sensibility was brought into dynamic interplay with the powerful modeling, simulation, and optimization capabilities of Dassault Systèmes’ cloud-based ecosystem. Within Dassault’s 3DEXPERIENCE® cloud platform, design and engineering teams leveraged AI‑powered virtual twins, real-time topological optimization, and life-cycle assessment to drive structural innovation from day one.

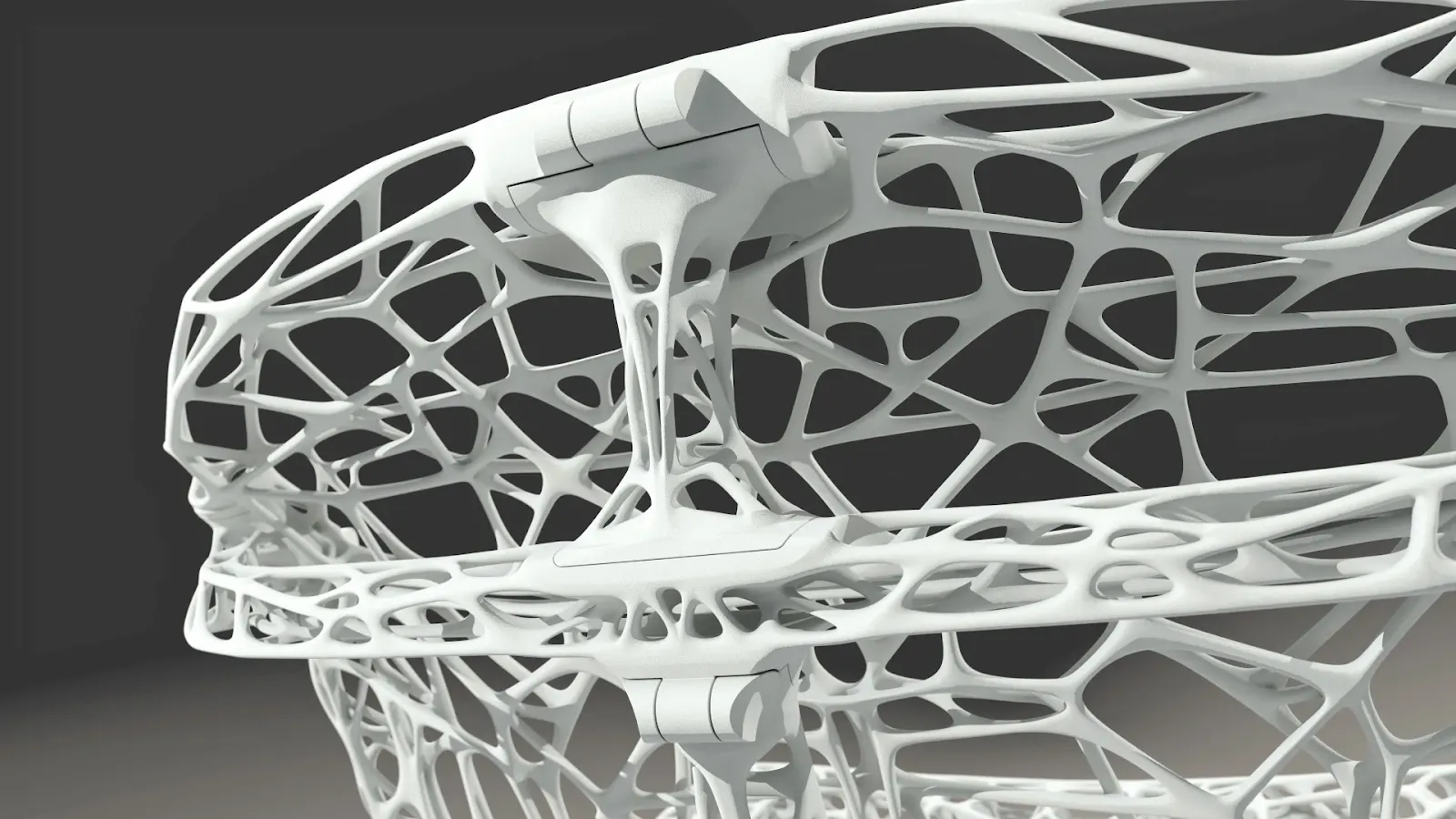

This integration allowed the team to simulate mechanical behavior under stress, explore different configurations, and optimize geometry, all while maintaining the sculptural integrity that Jouin is known for. Topological optimization played a critical role in shaping the chair’s structure to ensure strength, stability, and elegance with minimal material use.

Biomimicry at the Core

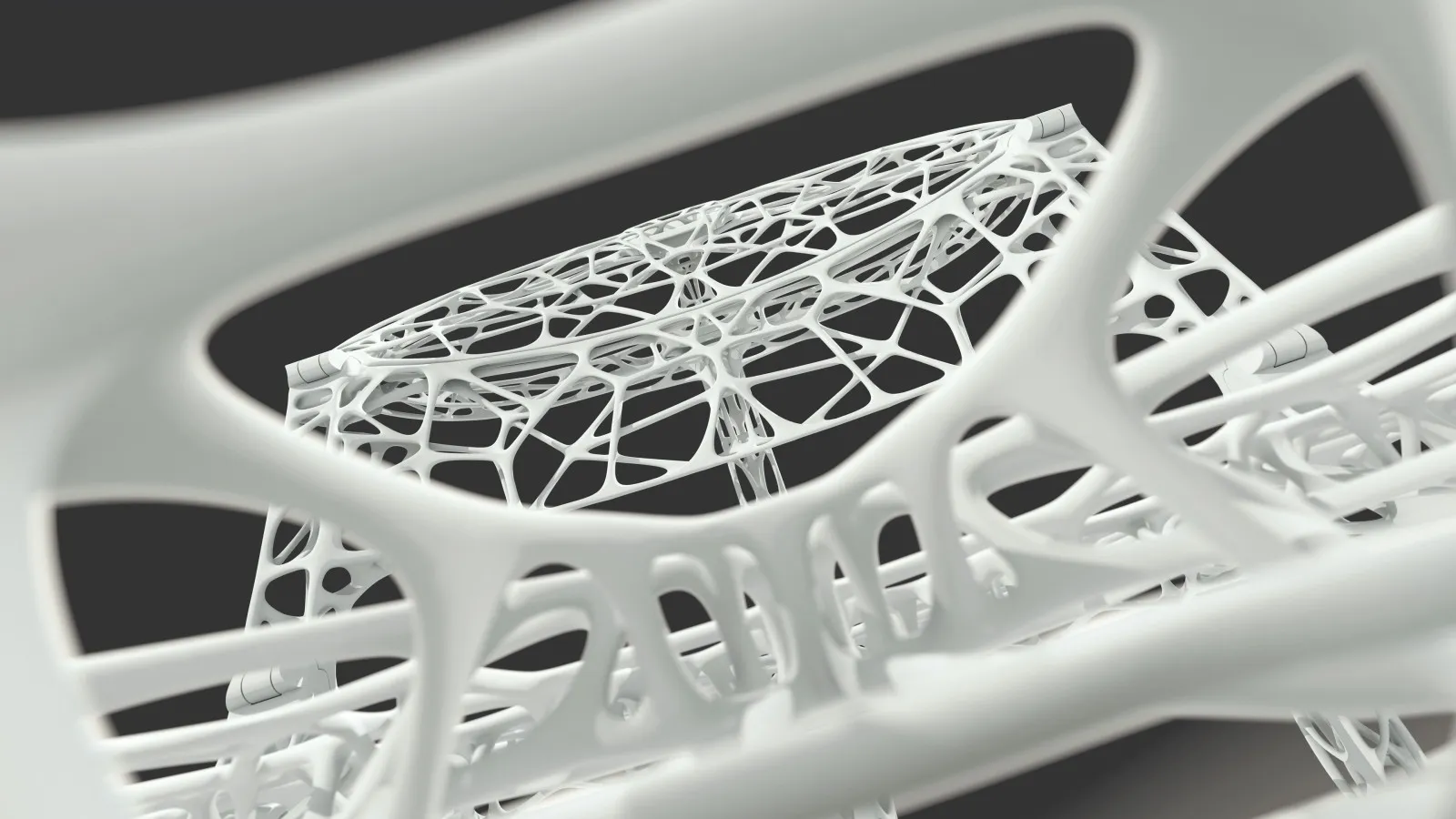

Central to Ta.Tamu’s design is a biomimetic approach, where inspiration was drawn from nature’s logic, specifically, the internal structure of bones and the articulation of joints in the human body. These natural systems, refined over millions of years, offer unmatched efficiency in balancing strength and weight.

This philosophy resulted in a lattice structure that weighs just 3.9 kilograms (8.6 pounds) yet can support up to 100 kilograms (220 pounds). This weight reflects a 75% reduction relative to a solid form and signals profound gains in material frugality. The open, bone-like grid distributes pressure evenly, providing both visual lightness and mechanical resilience. It’s a textbook example of design inspired by nature, optimized through digital tools, and executed with minimal waste.

Folded for the Future

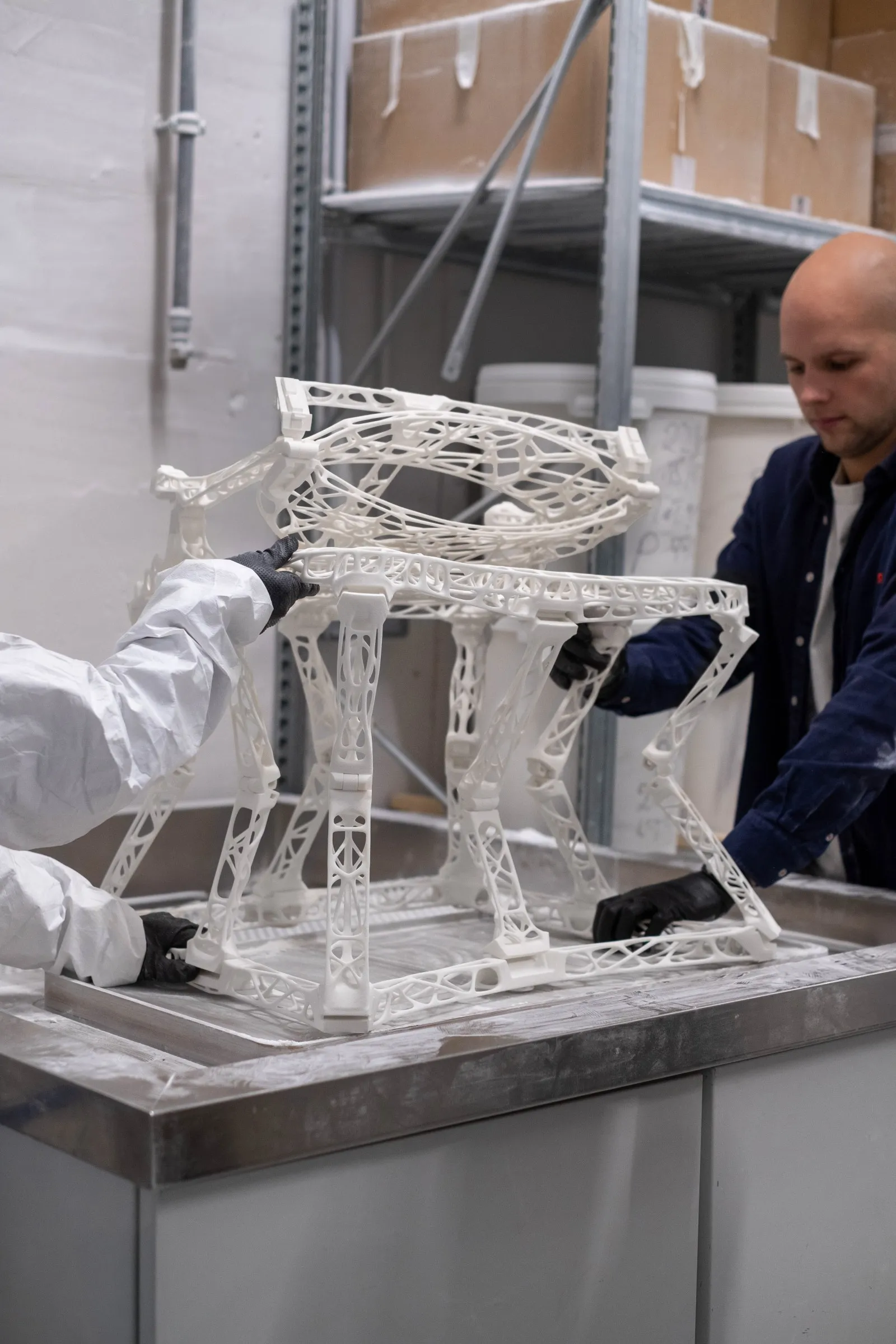

One of Ta.Tamu’s most striking technical achievement is that it’s 3D-printed in a flat, folded position, eliminating the need for assembly. This drastically reduces logistics, packaging materials, and post-production steps, all contributing to a more sustainable product lifecycle.

The chair can be deployed from its flat state to full functionality through a seamless unfolding mechanism, an innovation that emerged through constant simulation of hinge points, stress zones, and articulation behaviors using the virtual twin model.

Ta.Tamu is more than an elegant object. It represents a proof of concept for the generative economy, a vision of production where design, performance, and sustainability are driven by data, simulation, and collaboration. It’s a counterpoint to the linear, resource-intensive models of traditional manufacturing.

According to Anne Asensio, Vice President of Design Experience at Dassault Systèmes, “Ta.Tamu is a call to action for the industry to embrace a generative economy instead of continuing to create without limits.” By integrating life cycle assessment (LCA) and sustainability indicators from the earliest stages, the team was able to quantify environmental impact and refine their design choices accordingly.

Developed on AWS with technical support from Valtech, Ta. Tamu showcases how additive manufacturing and digital platforms can enable local, on-demand production, minimizing waste and carbon footprint. It represents the next stage in a design journey that began with Jouin’s 2004 Solid collection, evolving from form exploration to functional optimization.

At its core, Ta. Tamu is a study in how to do more with less. It’s a chair that reimagines structure, minimizes waste, and demonstrates how technology can amplify, rather than replace, human creativity.

By uniting nature’s principles with the precision of digital engineering, the team has shown a path forward for designers, manufacturers, and industries that aspire to create responsibly.

Ta.Tamu Chair Project Details

Project: Ta.Tamu chair

Collaborators: Dassault Systèmes and Patrick Jouin

Weight: 3.9 kg (8.6 lbs)

Load Capacity: 100 kg (220 lbs)

Platform Used: 3DEXPERIENCE® on the cloud

Key Features: Biomimetic design, foldable 3D printing, no assembly

Materials: Frugally used, optimized through AI and simulation

Development Time: 4 years

Image credit – 3ds.com/Dassault Systèmes

Leave a comment