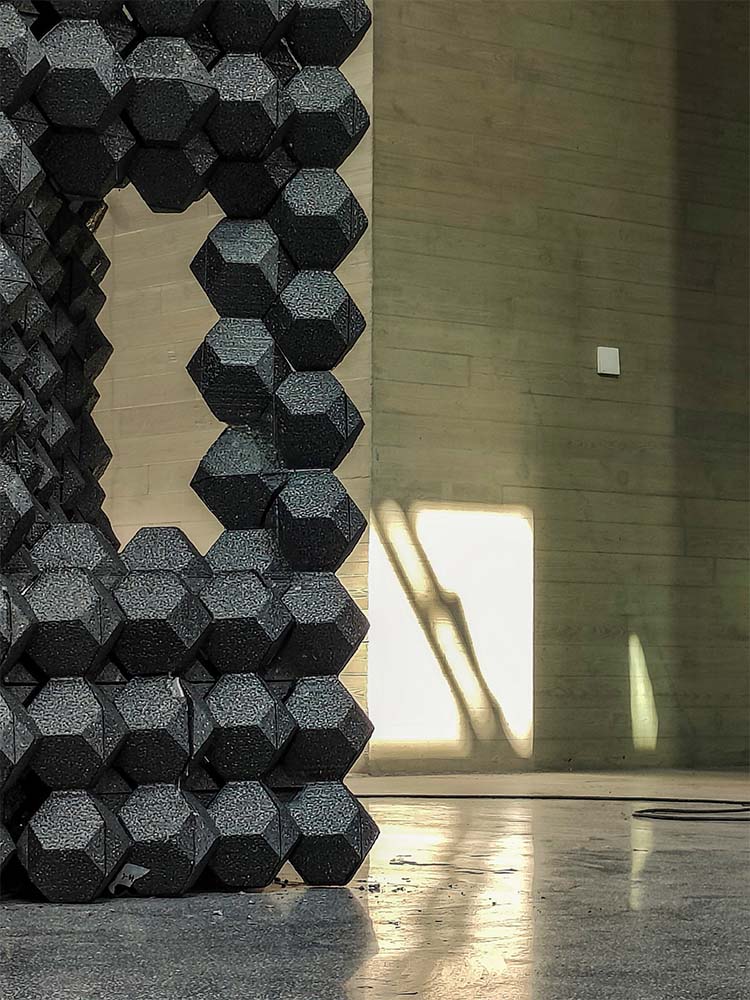

OctaFoam, which stands for “truncated octahedral matrix of ceramic foam,” is a porous brick wall structure that keeps heat in well. Large blocks of ceramic foam can be cut into custom parts quickly and without any waste by robots. A study and design group from Southeast University Nanjing and ETH Zurich collaborated to make this new prototype, which came out in November 2023.

OctaFoam is a skeleton-infill material that can be used to make walls that hold weight. The skeleton goes in four directions, and the filler fills in both sides of the walls, leaving big gaps in the middle. As a result, solids only take up 36% of the bounding space. They keep heat in and help the structure stay light. When it comes to mass production, one block of raw material is enough to build three times the wall volume of the first block. The prefabricated foam parts are put together like dry brickwork. The precise geometry of the parts and the interlocking system that was based on the Abeille vault made it possible for the confined brick structure (with tie columns and ring beams) to withstand the seismic load.

According to researchers, “The skeleton and infill are all made of ceramic foam and follow the same rotated discrete grid; as a result, there is no clear boundary between the two. One may add flat rectangular openings (windows or doors) in the wall or make the openings toward one of the possible four directions of the rotated grid. Such oriented openings are good for inviting sunlight or creating specific views.”

A diamond wire saw is often used to cut natural blocks like marble or light blocks like mineral foam or ceramic foam. OctaFoam is said to be made from big clay foam blocks that have been recycled. These blocks are better for the environment than regular bricks. As part of the study project, EPS foam was cut with hot wire to show that wire-cutting processes can work in general.

“Although limited to ruled surfaces (most commonly flat surfaces), the wire-cut technique stemming from traditional stereotomy contributes to a rich variety of complex structures based on combinations of irregular pieces. One classic case is the interlock ashlars of the Abeille vault.” said researchers.

Several related geometric shapes, like a row of truncated octahedra (shown in the linked video), can be seen as a single piece, which means they can all be cut from the raw foam block at the same time. This means that fewer steps can be taken in both cutting and putting things together. For the best results, the wall’s brickwork mechanism should be made so that it has the fewest parts and the shortest wire-cutting path possible, depending on the project. From the start, the study team thought that there would be a trade-off between good design and cost-effective production. Based on how well the cutting-stock problem worked, the shape of masonry parts has been slowly improved. In the end, the robotic toolpath and foam measurements were carefully set up to cut down on waste and production time.

OctaFoam has two types of designed porosity: the porosity in the material itself and the macro gaps that form when the wall moves. At both sizes, the material has a framework that works well. When OctaFoam is used in construction, a lot less raw materials may be needed, and the building will be stronger and more energy efficient. Computational geometry, robotic manufacturing, operations research, and the circular economy all work together to create new eco-friendly building methods.

Project Name: OctaFoam

Project Location: Nanjing, China

Design & Research project at Southeast University, Nanjing.

Design & fabrication: XIA Zhixiang, QIU Shubing, YANG Kaizhong, CHEN Siqi

Project director: Hao Hua (Southeast University) & Benjamin Dillenburger (ETH Zurich)

Leave a comment