Experiments are fun! Humans have explored and discovered numerous things out of their sheer curiosity and enthusiastic trials. NEST HiLo is a gaudian curved shell roof experiment by ETH Zurich & Block Research Group to investigate the feasibility of spraying a textile reinforced thin concrete using lightweight flexible formwork.

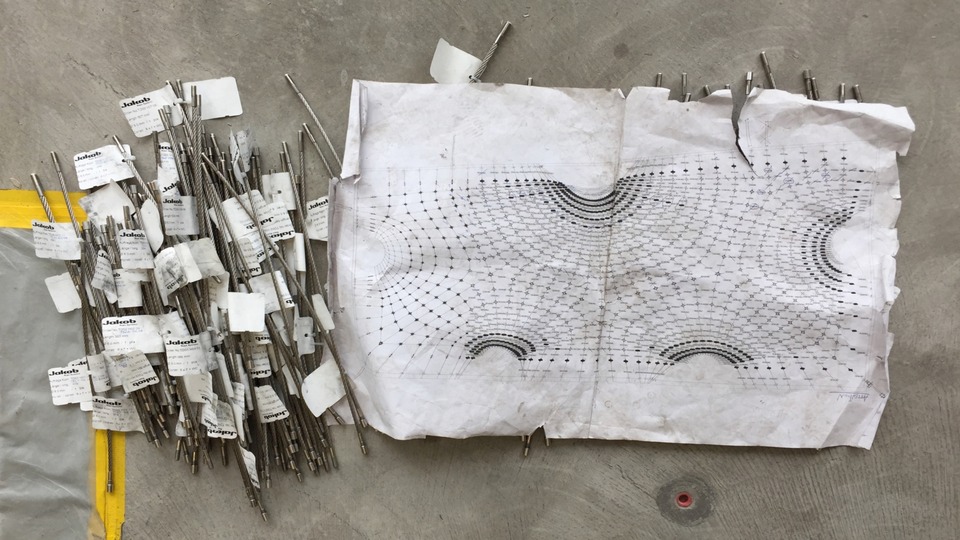

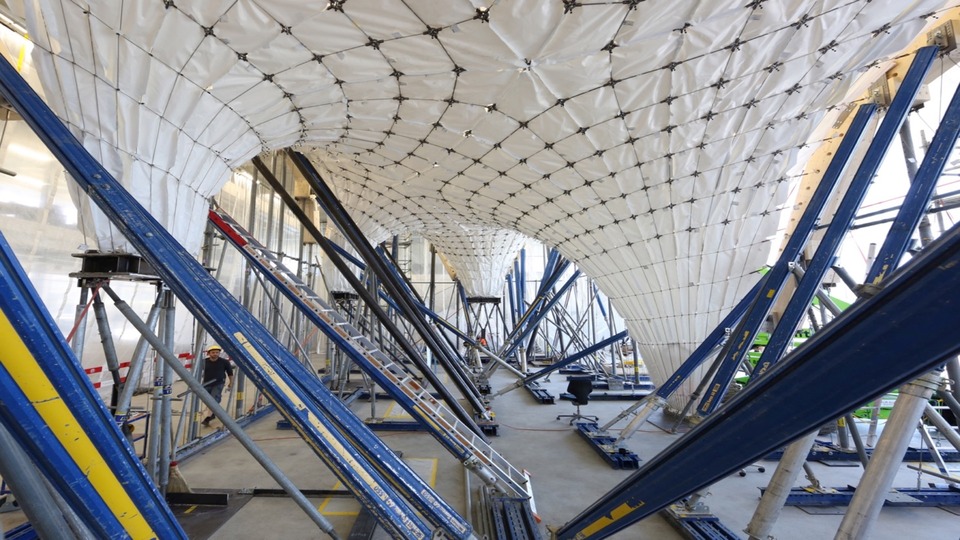

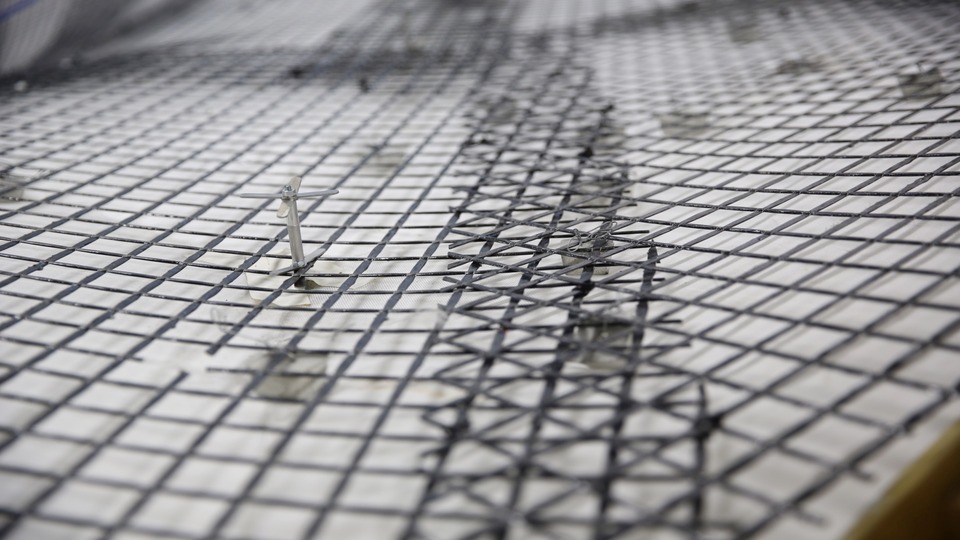

As a falsework, the team composed a tensioned cable net and tailored fabric as shuttering within a bounding box of 20m x 10m x 7m. The design was as such to dramatically reduce the material waste typically tangled in the construction of concrete shells. Improvising traditional formwork for doubly curved surfaces, which are usually customized using timber carpentry or milled foam. The web-like cable net spans within a reusable timber boundary supported by conventional scaffolding. After intrinsic calculations, the cable net was set to deform under the weight of the wet concrete into the desired curvy shape of the HiLo roof.

A non-uniform distribution of forces was induced using computational methods curated by Block Research Group. The full-scale prototype was built in the Robotic Fabrication Lab of the Institute of Technology in Architecture ETH Zürich. The prototype followed objectives such as developing and test the cable net components on a real scale, testing the feasibility of the system and the on-site logistics and testing the concrete spraying of a large and doubly curved surface through the carbon fibre reinforcement.

Advanced computational form-finding tools developed by the Block Research Group, specifically the Best-fit Thrust Network Analysis was deployed on the prototype. The intricate form-finding and augmenting methods for the design of the cable-net negotiated structural, architectural and fabrication constraints, such as respecting the glass facade lines, while abating the number of cables and nodes.

The experiment turned out to be a successful advancement in envisioning the cable-net and fabric formwork system, significantly due to the node component. The node ensured that the cable had ample freedom for reshaping the net, also simplified fabric placement and textile reinforcement in their proposed positions. This enabled to sculpt out precise concrete thickness at any given point on the curvaceous shell.

The prototype ingeniously demonstrated overcoming millimetre imperfections by adapting the forces in the cables to steer the shape from an imperfect starting point towards the desired silhouette, utilizing a control system. The Automatic Control Laboratory at ETH, derived an algorithm to determine the amount of tension applied to each boundary cable, thus enabling the shape of the cable-net towards the configured one. Within one round of control and re-tensioning, the shape deviations were reduced by 50% to an average of 40mm. This proved substantial for many potential applications in the construction industry, from cable-stay bridges to large stadia.

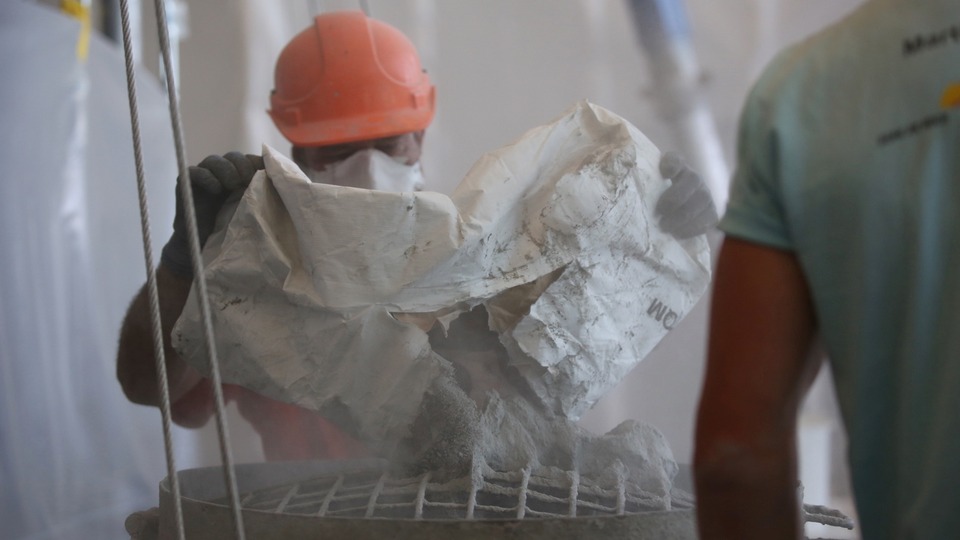

The NEST HiLo prototype also surveyed spraying a thin layer of concrete through the carbon fibre reinforcement onto the fabric shuttering. The technique stemmed from a solid concrete shell, which varied in thickness from 3 cm at the boundaries to 12 cm at the support points. Spraying onto the fabric shuttering gave the desired pillowing effect on the underside of the shell, which will provide an exciting and complex shape to the interior of the unit.

The exploration of the NEST HiLo roof prototype presented an ideal demonstration of the capabilities in computation framework for architectural and structural design masterly crafted by ‘compas’ developed by Block Research Group within the NCCR in Digital fabrication. From the form-finding process to the node design and the control system, compas was indispensable as the main library for geometrical operations, algorithms and data structure analysis.

Design and Engineering:

- Block Research Group, ETH Zürich

- supermanoeuvre

- Bollinger + Grohmann Ingenieure

Fabrication:

- Jakob (cables, cable-net rods)

- Bruno Lehmann (cable-net nodes and connections)

- Blumer Lehmann (edge beam)

- Dafotech (steel supports)

- Bieri (fabric cutting and sewing)

Construction:

- Marti Construction SA

- Bürgin Creations

Suppliers:

- Solidian (carbon fibre reinforcement meshes)

- Proserve (fabric)

- Doka (scaffolding elements)

- Holcim Schweiz (concrete)

Collaborators:

- Institute of Structural Concrete, RWTH Aachen

- Mathematical and Physical Geodesy, ETH Zürich

- Automatic Control Laboratory, ETH Zürich

Sponsors:

- ETH Zürich

- Holcim Schweiz

- NCCR Digital Fabrication

Acknowledgments:

Cristián Calvo, Alessandro Dell’Endice, Philippe Fleischmann, Ursula Frik, Naida Iljazovic, Alexander Kobald, Juney Lee, Michael Lyrenmann, Ammar Mirjan, Mariana Popescu, Andreas Reusser, Matthias Rippmann, Alexander Nikolas Walzer, Hongyang Wang

Leave a comment