This article explores the use of 3D-printed housing as a post-disaster temporary shelter for disaster-affected areas. “Approximately 23 million people have been displaced from their homes every year since 2008 and the numbers are projected to be even larger in the future due to increases in weather-related calamities and population density” write Subramanya and Kermanshachi in a paper.

North American Wildfires, floods in Pakistan, hurricanes, tornados, cyclones, storms and blizzards, the Russian invasion of Ukraine, and earthquakes in Indonesia or Turkey – the latter claiming over 43.000 fatalities and over 80.000 thousand destroyed buildings and counting – are just some of the tragic disasters that happened globally and recently. Some of these are man-made disasters and others are natural catastrophes but all of them erase cities and villages, make roads untraversable, and require quick responses on a humanitarian scale from local governments and other organizations. The people lucky enough to escape these tragedies find their homes often destroyed and inhabitable, pushing architects and engineers to be quick, creative, and adaptive in terms of temporary shelter and housing.

In architectural history, emergency housing solutions have been carried out in various ways. In post-war Germany, architect Otto Bartning erected emergency churches (German: Notkirchen), often made from bricks of previously destroyed churches and other houses. For that, Bartning developed their own typology and design to be able to construct them quickly. Beyond that, one may also remember the mobile hospitals (called Fangcang hospitals) developed and used by China during the Covid-19 pandemic and previous earthquakes in Sichuan and Yushu, which could be assembled quickly in addition to existing hospitals.

Temporary shelter, according to the work of Subramanya and Kermanshachi can be categorized into four different categories: Emergency Shelters, which is lifesaving and immediate; Temporary Shelters such as tents for individual or groups; Temporary Housing that is often more rigid and equipped than shelters and Permanent Housing, which (still) can be erected quickly and cost-efficiently in case of urgency. Whereas it entirely depends on the disaster that happened and the available material and financial resources, in reality, emergency and temporary shelters solution end up often becoming rather permanent accommodations for people. Consequently, not enough investments are done in the infrastructure of such shelters or settlements. For example, according to a report by the International Rescue Committee (IRC), there was one shower for 80 refugees on the Greek island of Lesbos as well as one toilet for 70 people. Sewage water came as high as the mattresses that people sleep on.

Additionally, conflicts and accompanying mental health challenges have driven the suicide rate enormously and led some refugees to finally burn their own shelters down. The newer tents provided by the United Nations High Commissioner for Refugees were meant to be temporary, but are meanwhile rather used permanently. Whereas this is a complete failure on the political level, architects and engineers can mitigate these challenges and are meanwhile working on a solution that could provide better housing in a shorter time for less money.

3D-printed housing is being explored by more and more companies, which specialize in different aspects of it. Here are some examples taken from the 3dp-Magazine: “Icon is a Texas-based developer of advanced construction technologies including robotics, software, and building materials. Apis Cor (from Florida) creates specialized equipment with the capability of printing an entire building (walls and structures) on site. Their mission is to develop fully-autonomous equipment that can print buildings on Earth and beyond.

World Advanced Saving Project (WASP), makes large construction 3D printers and partners with companies interested in eco-sustainable 3D printed habitats and buildings with local materials. Winsun is a pioneer in 3D printing that started as a material supplier and made headlines in 2014 for printing ten houses in one day. There are many more companies, some of them focusing on the aspect of sustainability, others on the software, machine learning, and machines needed, and again others more on the design. Overall, “[…] the global market for construction using 3D printing is expected to reach $114.4 million in 2023,” writes Amelia H. in The Role of Construction 3D Printing in Humanitarian Aid. That said, whilst also taking jobs, 3D-printing technologies will also create new jobs and require construction workers to potentially acquire new skill sets.

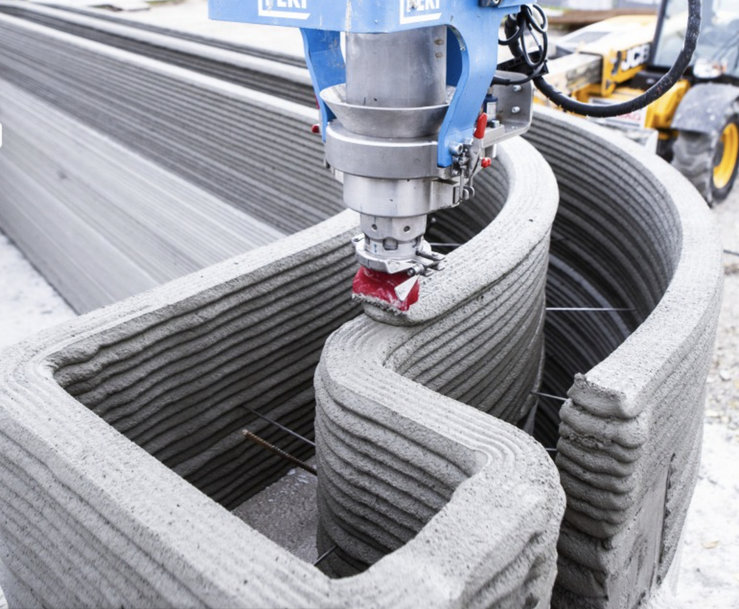

Generally, technology has moved far beyond the initial 3D printers that started to become popular around 20 years ago. Printers can create housing, layer by layer, of different materials, depending on the climate and requirements at the location: sand and cement, various concrete mixtures, clay, silt, rice straw, vegetable fibre, and natural waste (including any biodegradable material from plants or animals). Hereby, the 3D-printed buildings can have a bioclimatic character, providing mild air in hot summer and a warming environment in cold winter write Subramanya and Kermanshachi in their paper. The main advantages of such technology are manifold: it is quick and cheap.

San Francisco-based company Icon claims to be able to erect a 55 to 75 square meter home in just 24 hours for $4,000 or less, whereas the average cost for the same-sized house made of conventional materials such as concrete or brick and mortar is, at least, 40 times as much. However, 3D-printed housing is a market in itself and so also more luxurious versions can be found.

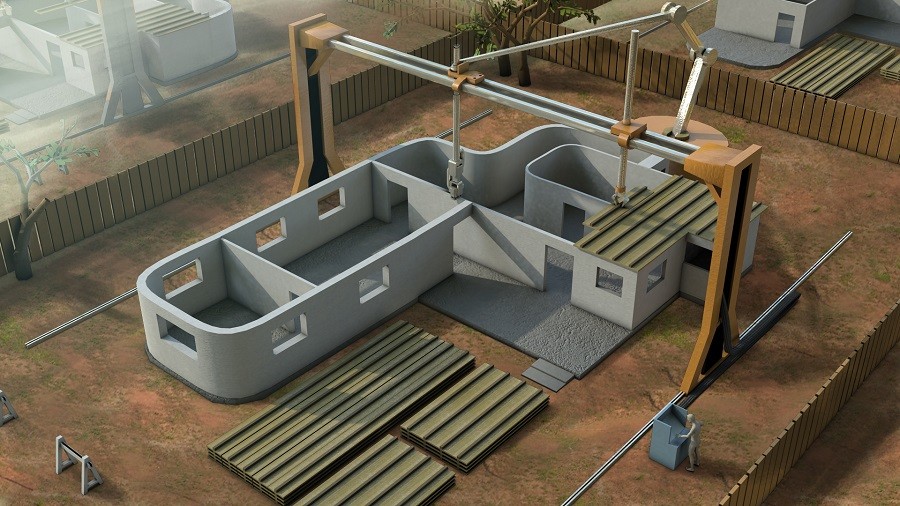

How the construction process works is, for example, well-explained by the TikTok channel thelayerlord: the necessary tools include the printer, a control panel, a monitor, a silo with the dry material stored, a mixing, and a pumping system. The dry material in connection with water feeds the printer, which will then move along the wall of the building layer by layer and vertically, based on a pre-designed CAD file. Sometimes, two outer walls with space between them are printed and in this space, plumbing and electrical wires as well as insulation can be placed if needed. Doors and windows are left out as gaps. When walls next to doors and windows are high enough, a reinforcement is added above them (such as a steel plate), where the printer can lay more layers of concrete. Every house usually consists of hundreds of layers, and each of them can be printed in a few minutes. Depending on the nozzle of the printer arm, the layers can be more curved or flat to the outside.

To print a house, various techniques can be applied. Elements such as walls can be prefabricated before a disaster occurs and simply assembled if needed. Otherwise, machines can 3D-printed houses on the spot; hereby aerial robotic drones can help to scan the area and model the landscape using Building Information Management (BIM) systems. It is further so that some prototype drones can already fix certain piping and in the future may be able to assist the building process in various ways, perhaps up to a point where the little human workforce is needed to establish a temporary shelter or housing solution.

The article ‘The Role of Construction 3D Printing in Humanitarian Aid in 3D-Natives’ further states that “[…] while certainly an innovative and efficient method of combating issues relating to lacking social infrastructure and in particular the housing and education crises, 3D-printing technology first and foremost requires funding and support. This is especially true as current construction additive manufacturing methods are still far from comprehensive, some parts of the school cannot be 3D printed. These parts include the roof, doors, and windows.” Therefore, there are certain limits to the technology, further limited by the low yet increasing amount of companies who are offering this technology as well as the skills potential workers of 3D-printed housing need. Additionally, the geographic area within which such housing is often needed (due to climatic catastrophes) tends to be not the area where such technology is first and foremost developed.

Nevertheless, as technology improves in its variety of design and application possibilities, 3D-printed housing as well as other types of prefabricated and easily assembled housing – such as Boxable’s prefabricated and foldable tiny homes – are important for the future, where disasters might become more the norm than the exception. It will be further relevant that sustainability and creative designs are at the center of this technology: On one hand, so that not every building in the world looks the same and rather conserves a local character through local materials, on the other hand, to ensure a smooth integration into natural areas and reduce transport cost for machines, precisely because of this geographical mismatch in term of where it is produced and where it is needed.

Leave a comment