In an era increasingly defined by material scarcity and ecological urgency, the construction industry faces a crucial turning point. Among the vast quantities of materials discarded each day, wood, particularly in the form of irregular off-cuts, stands as a striking example of untapped potential. These complex fragments, typically byproducts of traditional manufacturing and construction processes, are often overlooked, destined for landfills or downcycled into low-value products like mulch or particleboard. This linear consumption model is unsustainable and represents a significant loss of a valuable, renewable resource.

“From Waste to Wonder” challenges this wasteful trajectory. Designed by architects Jianing Luo and Boyuan Yu, this research initiative introduces the Sustainable Building Design and Construction (SBDC) framework, a systematic methodology that reimagines off-cut wood as a viable, high-value architectural component, furniture, and even entire buildings. This new methodology opens a pathway toward a circular construction economy, transforming architectural waste into wonder through technological innovation and digital craftsmanship.

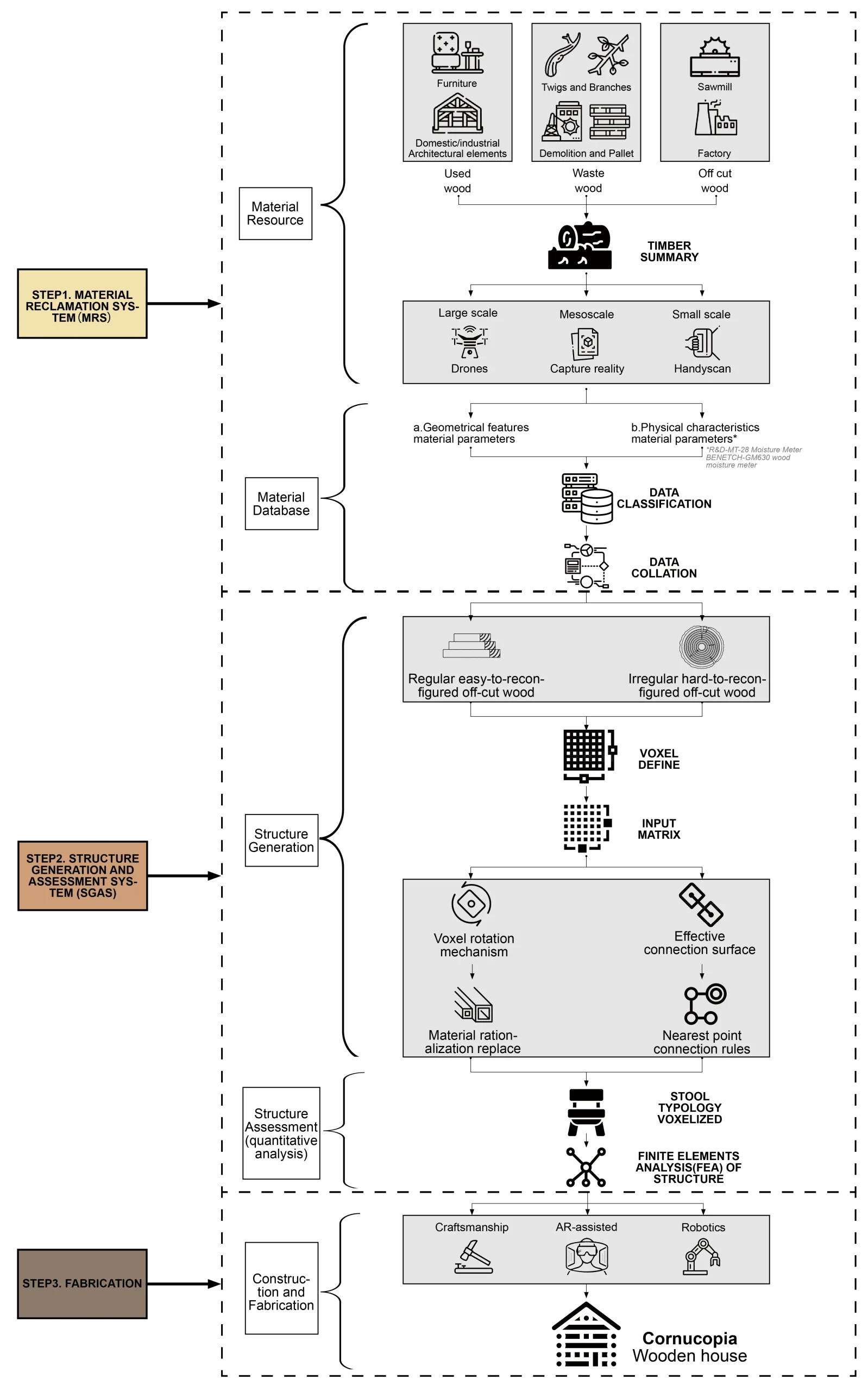

At the core of the project is a three-step process, each stage integrating advanced tools from green technology, computer science, and material engineering.

1. Material Reclamation System (MRS)

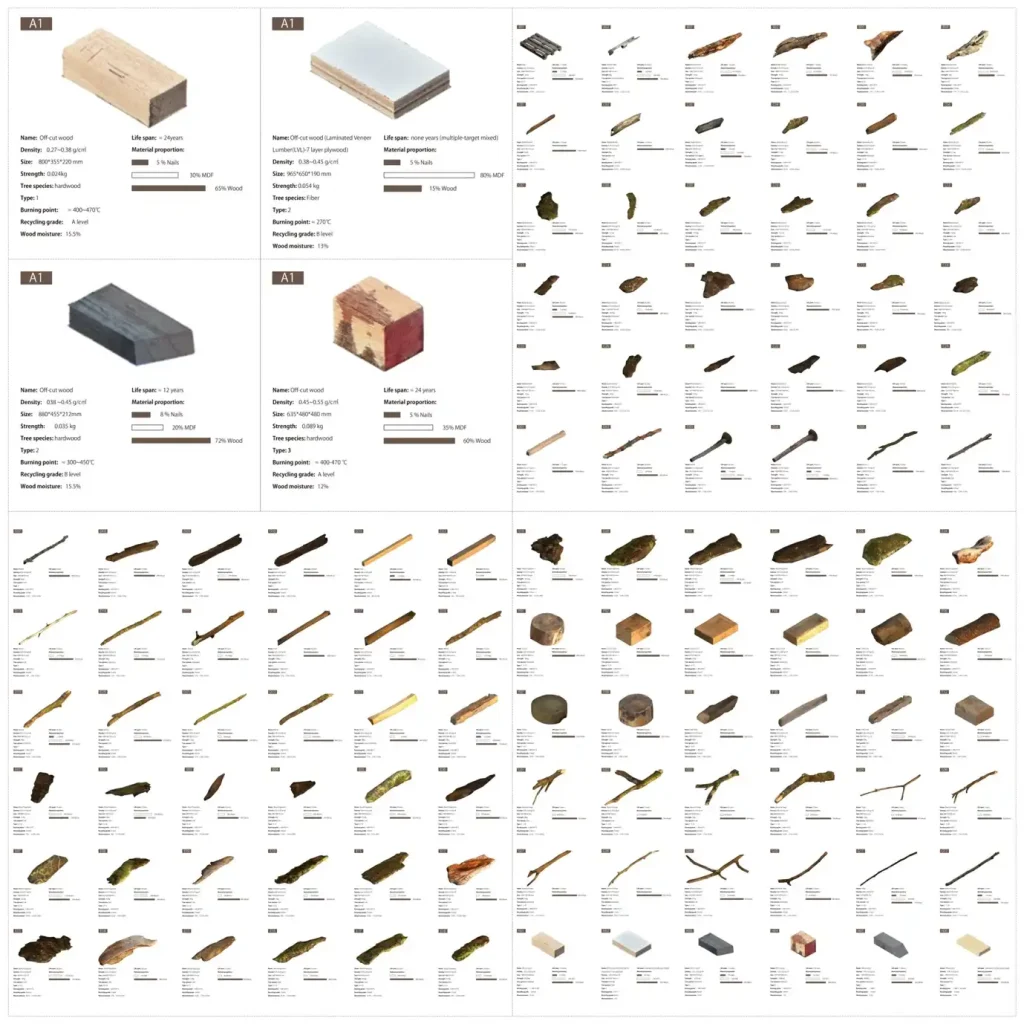

The initial stage involves creating a detailed digital inventory of the wood waste. Using high-precision 3D scanning technologies such as LiDAR and photogrammetry, off-cut wood pieces are scanned to capture their geometry, material type, density, and structural integrity. The system compiles all of this information into a comprehensive digital inventory, effectively turning discarded wood fragments into a well-organized, searchable material library.

An unusable collection of scraps is now a set of ready-to-use digital assets, primed for the next phase of design. This foundational database becomes the backbone of the framework, enabling thoughtful reuse and data-driven design at every stage that follows.

2. Structural Generation and Assessment System (SGAS)

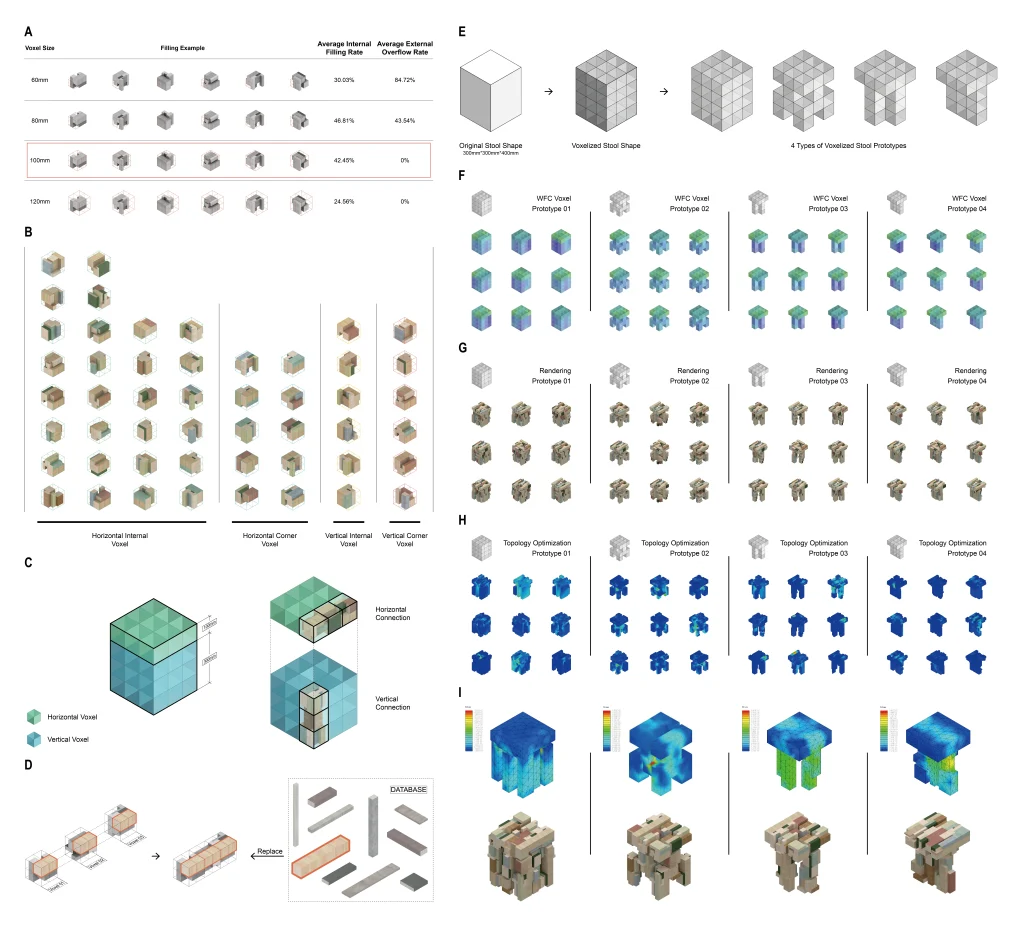

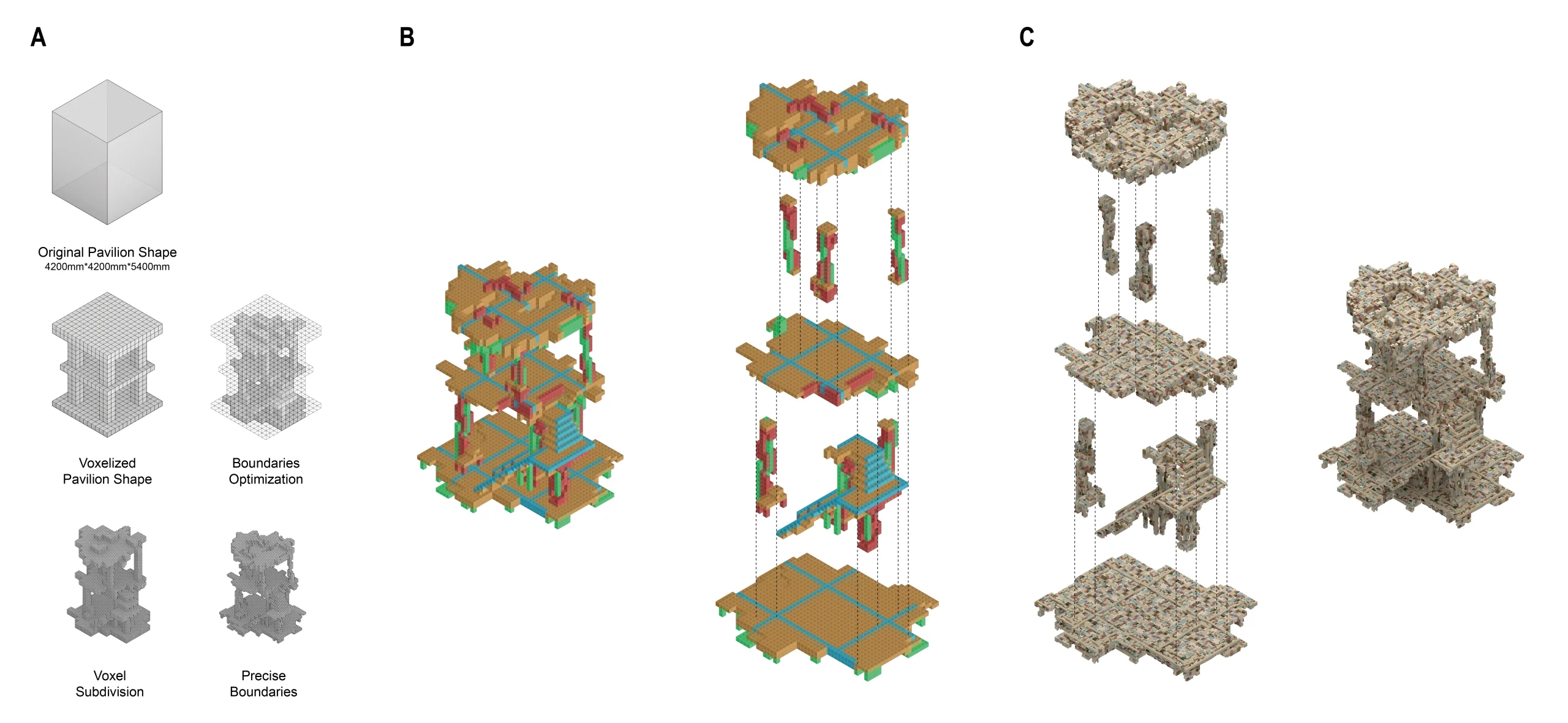

The Structural Generation and Assessment System (SGAS) is a powerful engine of design innovation. This stage transforms raw material data into buildable forms using a voxel-based approach, where scanned off-cut wood pieces are digitally packed into modular structural units, or “voxels.” These voxels act as building blocks, enabling the system to create complex architectural components and furniture designs from irregular material.

Driving this process is an algorithm known as Wave Function Collapse (WFC), which intelligently arranges the pieces to maximize both spatial efficiency and design potential. Before anything is built, each generated structure is rigorously tested in a virtual environment using Finite Element Analysis (FEA), a digital simulation tool that evaluates structural performance under real-world stresses and loads.

The SGAS stage bridges creative exploration with architectural responsibility, pushing reclaimed material to perform beyond expectation.

3. Fabrication

Once designs are digitally validated, they move into fabrication. Here, the project explores a spectrum of assembly techniques from traditional joinery to robot-assisted manufacturing and AR-guided assembly. This stage bridges the gap between virtual design and physical construction, allowing complex digital models to be accurately translated into real-world objects.

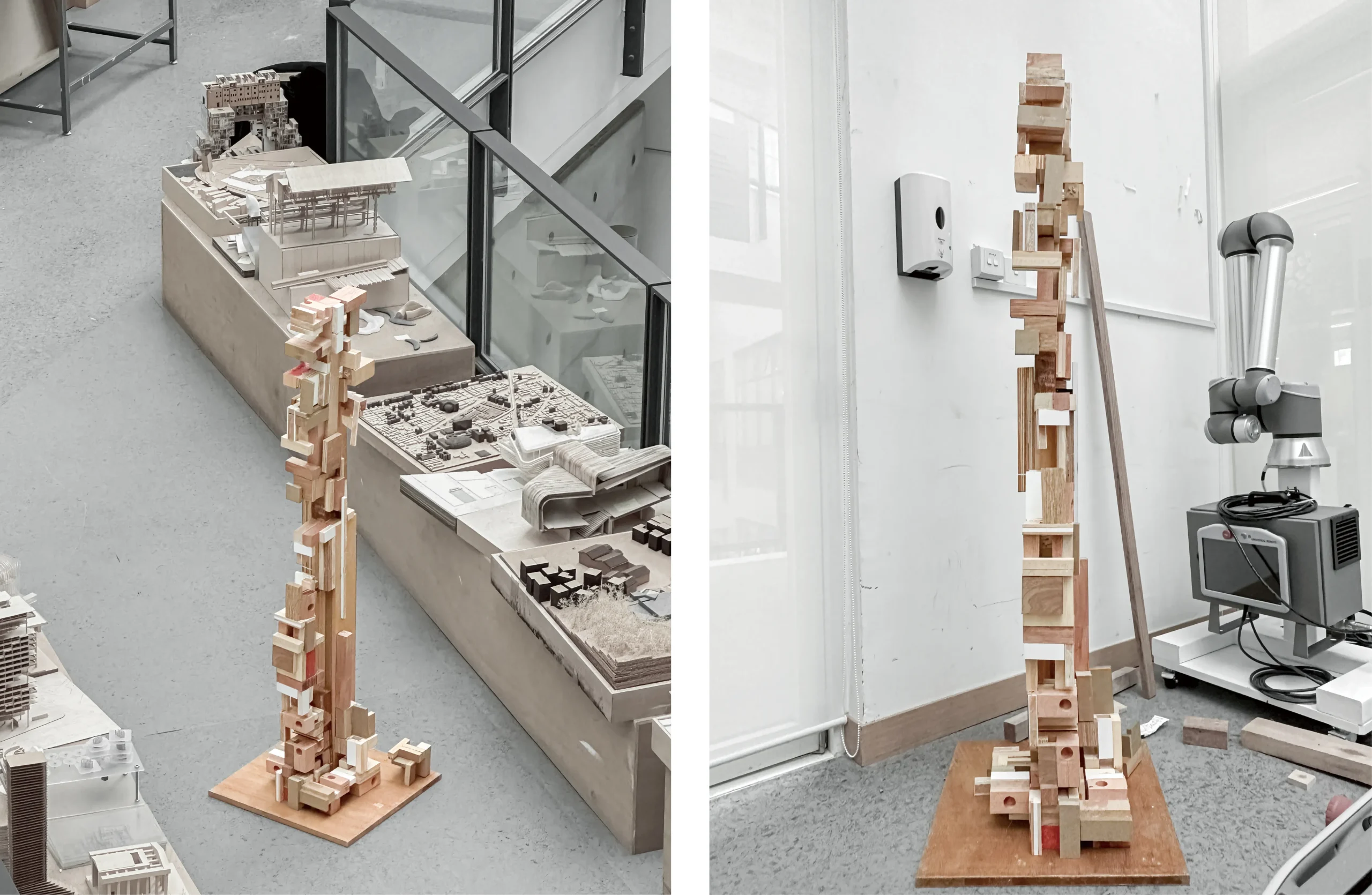

To validate the framework’s effectiveness, the research team has developed and constructed a series of full-scale prototypes, each testing the system’s adaptability across varying design scales and typologies.

Among these are an intricately crafted stool, a load-bearing column, and a larger architectural installation titled the “Primitive Hut,” a pavilion that exemplifies the spatial and structural potential of algorithmically assembled waste wood. These built case studies provide compelling proof-of-concept, illustrating the framework that reclaims material value and delivers design outcomes that are both architecturally expressive and structurally robust. Collectively, they affirm the viability of upcycling irregular off-cut wood into meaningful, high-performance architectural forms.

The project extends far beyond conventional recycling practices; it articulates a visionary framework for sustainable architectural innovation. By establishing a systematic, technology-driven model for material upcycling, the SBDC framework repositions off-cut wood as waste & a primary design material. Its replicable methodology empowers architects, designers, and builders to integrate reclaimed resources into the core of their workflows, aligning with the principles of the circular economy.

As the construction industry seeks actionable strategies to reduce its ecological footprint, the framework represents a critical step toward closing the material loop, transforming linear waste streams into platforms for structural performance, aesthetic innovation, and regenerative design practice.

From Waste to Wonder Project Details:

Architects: Jianing Luo, Boyuan Yu

Project Type: Virtual / Metaverse Design

Typology: Experimental / Research-Based Architecture

Software Used: Rhinoceros3D, Grasshopper3D, V-Ray, Enscape, Unreal Engine

Project Status: Conceptual Design – Prototypes Built

Images courtesy of Jianing Luo and Boyuan Yu.

Leave a comment