Buga Wood Pavilion designed by ICD/ITKE at the University of Stuttgart.

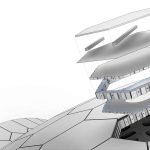

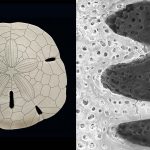

The BUGA Wood Pavilion celebrates a new approach to digital timber construction. Its segmented wood shell is based on biological principles found in the plate skeleton of sea urchins, which have been studied by the Institute for Computational Design and Construction (ICD) and the Institute for Building Structures and Structural Design (ITKE) at the University of Stuttgart for almost a decade. As part of the project, a robotic manufacturing platform was developed for the automated assembly and milling of the pavilion’s 376 bespoke hollow wood segments. This fabrication process ensures that all segments fit together with sub-millimetre precision like a big, three-dimensional puzzle. The stunning wooden roof spans 30 meters over one of BUGA’s main event and concert venues, using a minimum amount of material while also generating a unique architectural space.

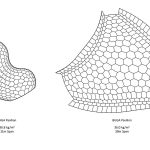

The BUGA Wood pavilion provides an architectural attraction at the central summer island of the Bundesgartenschau 2019 in Heilbronn. The design of the pavilion is based on morphological principles of the plate skeleton of sea urchins. Following the precursor research building of the same project team, the LAGA Exhibition Hall in Schwaebisch Gmuend, the research goal of the BUGA Wood Pavilion is pushing the architectural articulation and structural performance of biomimetic segmented wood shells onto a new level: With the same small amount of wood per square meter as in the LAGA project, is it possible to build a shell that reaches triple the span? And can this structure remain fully reusable, so that it can be deployed on a different site after the BUGA without any loss of performance?

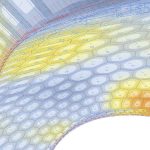

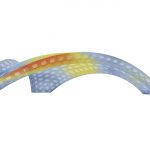

To achieve this goal, the pavilion builds on the biomimetic principle of using “less material” by having “more form”, both on the level of the overall shell and its individual segments. In order to minimize material consumption and weight, each wood segment is built up from two thin plates that plank a ring of edge-beams on top and bottom, forming large scale hollow wooden cases with polygonal forms. The bottom plate includes a large opening, which constitutes a distinctive architectural feature and provides access to the hidden connections during assembly. The lightweight building elements are connected by finger joints, which follow the morphological principles of anatomic features found on the edge of sea urchins’ plates. In the assembled state, the shell works as a form-active structure through its expressive doubly-curved geometry.

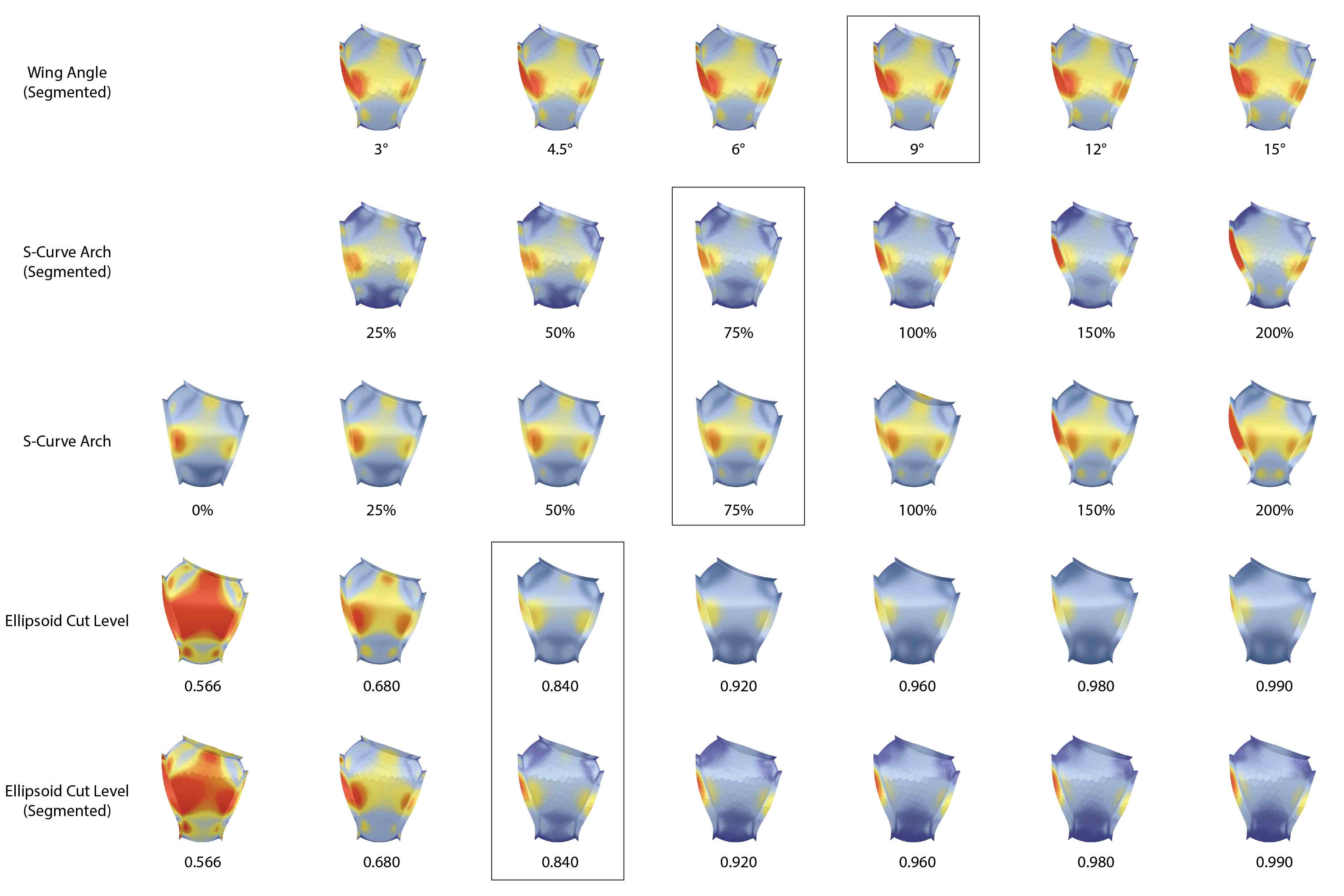

New ways of building require new ways of designing and manufacturing. The BUGA Wood pavilion was conceived under the paradigm of Co-Design, where novel possibilities in design, engineering and fabrication are explored through continuous computational feedback within an interdisciplinary team. In this project, the co-design algorithms developed by the project team generate the shape of each element of the pavilion according to architectural design intent and structural requirements, while all robotic fabrication aspects are directly embedded and negotiated. The design of the pavilion happens concurrently and in feedback with the design of the robotic manufacturing set-up, which is a bespoke development for the project. The highly integrative process enables the design and engineering of 376 unique plate segments with 17 000 different finger joints in response to multifaceted design criteria, from the scale of the overall structure down to sub-millimetre details.

Without any loss of precision, this multi-scale approach allows addressing architectural and structural considerations concurrently. Despite the pioneering character of the project, and despite an incredible short development time of only 13 months from commission to the opening, the integrative computational process allows for the careful design of each building element in minute detail.

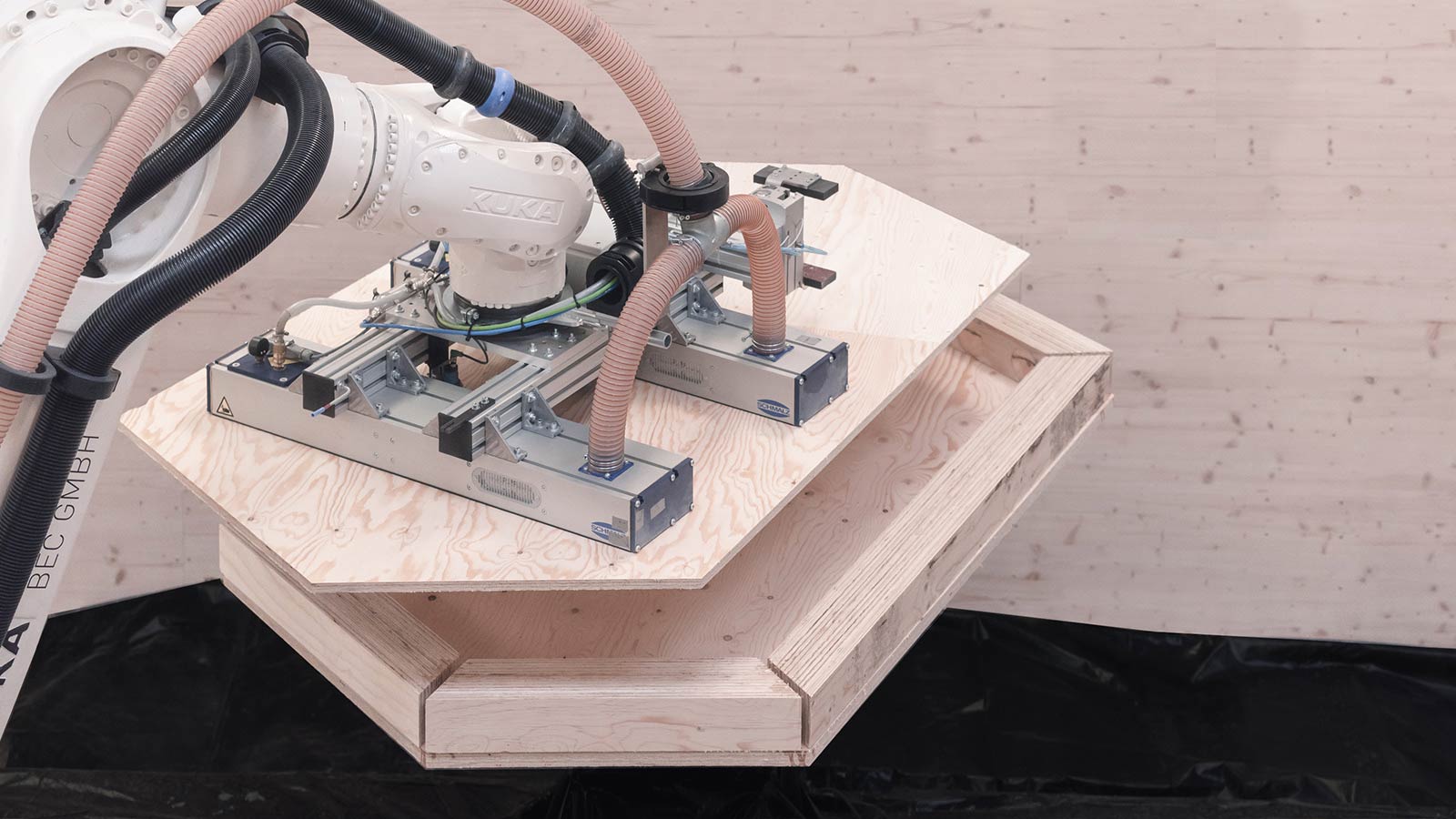

Compared to a solid wood plate, as for example used in the team’s LAGA Exhibition Hall, the hollow building segments significantly reduce weight and material, but they increase the number of building parts eightfold and lead to more complex manufacturing. Thus, striving for higher resource efficiency needs to go hand in hand with automated robotic manufacturing of the shell segments. For this, a novel, transportable, 14-axes robotic timber-manufacturing platform was developed by ICD University of Stuttgart and BEC GmbH, and located at the industrial partner MuellerBlaustein Holzbauwerke GmbH for production.

Project Partners :

ICD – Institute for Computational Design, University of Stuttgart

Prof. Achim Menges, Martin Alvarez, Monika Göbel, Abel Groenewolt, Oliver David Krieg, Ondrej Kyjanek, Hans Jakob Wagner

ITKE – Institute of Building Structures and Structural Design, University of Stuttgart

Prof. Jan Knippers, Lotte Aldinger, Simon Bechert, Daniel Sonntag

with support of :

Jorge Christie, Rebeca Duque Estrada, Robert Faulkner, Fabian Kannenberg, Guillaume Caussarieu, Bahar Al Bahar, Kyriaki Goti, Mathias Maierhofer, Valentina Soana, Babasola Thomas

Müllerblaustein Bauwerke GmbH, Blaustein

Reinhold Müller, Daniel Müller, Bernd Schmid

BEC GmbH

Matthias Buck, Zied Bhiri

Bundesgartenschau Heilbronn 2019

Hanspeter Faas, Oliver Toellner

Project Building Permit Process:

Landesstelle für Bautechnik

Dr. Stefan Brendler und Dipl.-Ing. Willy Weidner

Proof Engineer

Prof. Dr.-Ing. Hugo Rieger

MPA Stuttgart

Dr. Simon Aicher

Planning Partners :

Belzner Holmes Light-Design, Stuttgart

Dipl.-Ing. Thomas Hollubarsch

BIB Kutz GmbH & Co.KG, Karlsruhe

Dipl.- Ing. Beatrice Gottlöber

IIGS – Institut for Engineering Geodesy, University of Stuttgart

Prof. Volker Schwieger, Laura Balange, Urs Basalla

Project Support:

State of Baden-Wuerttemberg

University of Stuttgart

EFRE European Union

GETTYLAB

DFG German Research Foundation

Via : ICD/ITKE

I like the design