Concrete is an essential building block of the construction industry. It is the most globally consumed resource all around the world. Concrete is the essential frame of modern construction, we consume about 4 billion tonnes globally every year. It generates about 2.5 billion tons of CO2 emission (About 8%) every year. Concrete is a versatile material whose adaptability factor has applications on various scales and levels for utilization in foundations, roofing, walls, floors, cladding, and infrastructure – bridges, dams, etc.

Concrete is an essential construction material that contains flaws that can impact one’s health and environment. Concrete production (Industrial sector) is responsible for producing harmful greenhouse gases to the environment. Hence it is vital to produce concrete as materials in general with a low carbon footprint. With the growth of technology, concrete materials with less impact value are discovered. Materials that are more sustainable and safer for the environment are being utilized now and in the future.

Main sources of harmful CO2 Emissions to the environment;

The industries in general which produce materials, and products are a considerable source for these harmful CO2 emissions released into the environment. Some of the major industry contributors to the 8% CO2 emission every year;

a. Fuel and Power production

b. Chemical production

c. Cement/Concrete production

d. Metal production

e. Oil and gas production

f. Coal Mining

g. Transportation

h. Landfill of waste

i. Cultivation and Agriculture production

j. Machinery Production

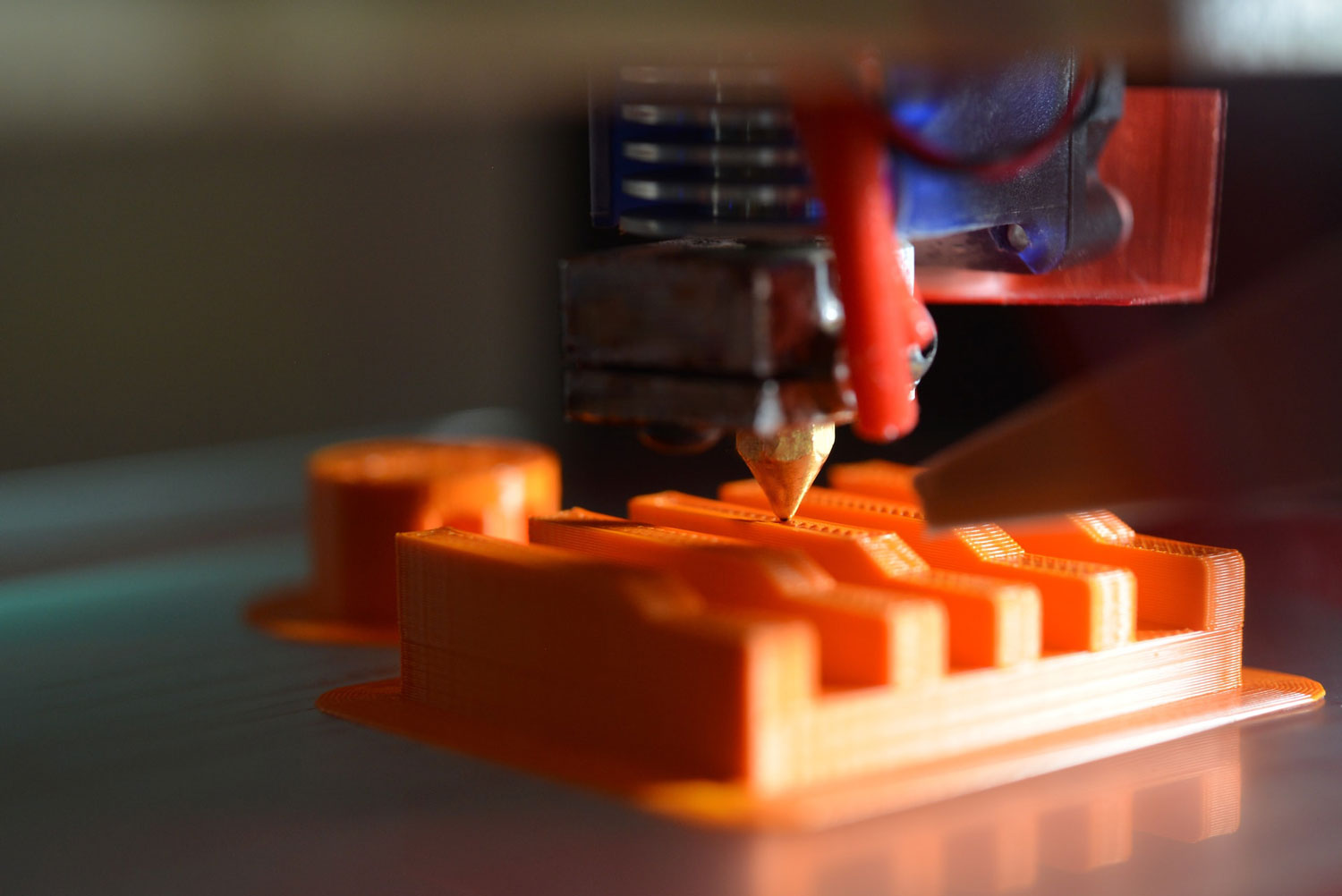

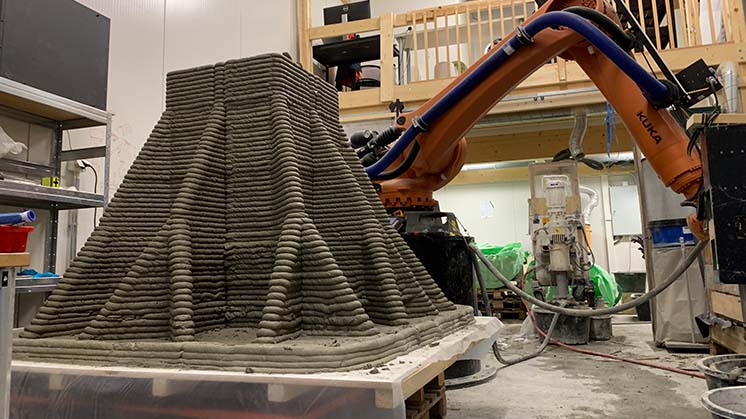

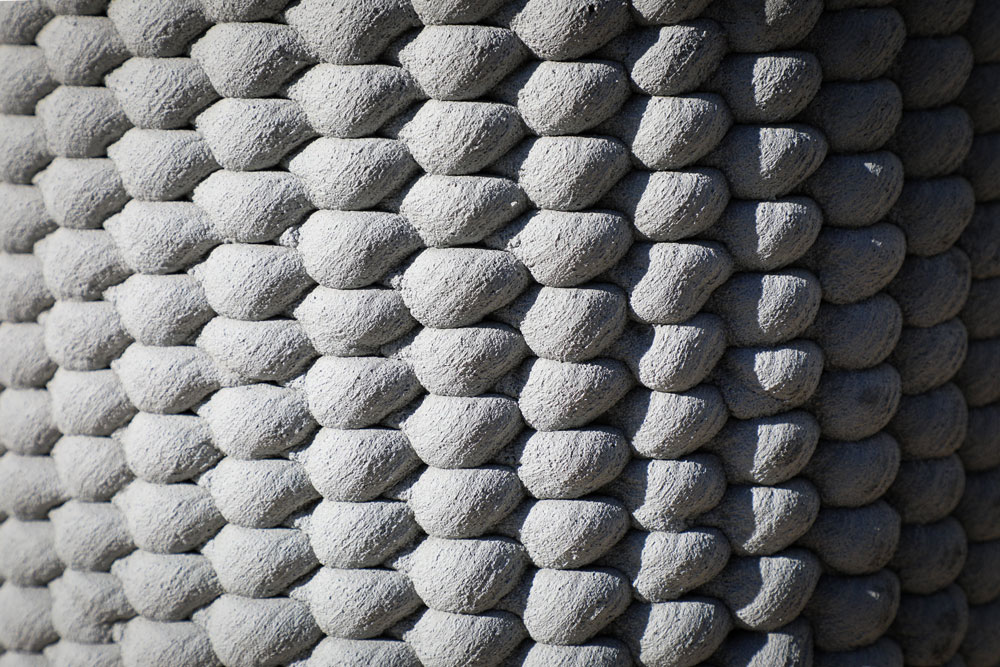

3D printing is considered one of the emerging advanced technologies which have proved beneficial in medical, aerospace, construction sectors, etc.3D printing is the future of advanced and precise building construction. Since it is an efficient and fast construction process 3D printing will be the preferred type of construction process in the future.3D printing is also evolving in terms of material usage. Some materials in 3D printing are plastic, metal, carbon fibre, concrete, mud, sand, and stone, etc.

What is Low Carbon Concrete?

Low-carbon concrete is a type of concrete that is produced by low-carbon footprint components compared to traditional material components. Low-carbon concrete is a more sustainable concrete option that can be utilized for construction. Low carbon concrete is a method of reducing carbon footprint and waste production.3DCP – 3D Concrete printing using low carbon concrete is being implemented by various 3d printing manufacturers like WASP, Hyperion Robotics, Siam Cement Group (SCG), Apis Cor, Icon, Peri group, XtreeE, etc.

What are the benefits of Low Carbon Concrete utilized in 3D printing?

Low Carbon Concrete utilized for 3D printing is preferred due to its sustainable characteristics as it reduces the carbon footprint and its safe for the environment.

Some benefits of utilizing low-carbon cement for 3D printing;

a. Environment-friendly material

b. Reduced the Carbon footprint

c. Reduce Concrete consumption

d. It helps reduce material usage

e. Reduce construction cost since formwork is not required

f. Fast and safe construction method in 3D printing

g. It is less harmful to one’s health

3D manufactures that utilize low-carbon concrete in 3D printing

Hyperion Robotics + Peikko Group

Project client: Iberdrola (A Renewable energy company)

Project collaboration: Hyperion Robotics + Peikko Group

Location: Helsinki/Lahti, Finland

Hyperion in collaboration with Peikko and Iberdrola designed and constructed the first 3d printed concrete pad foundation. Hyperion robotics, Iberdrola, and Peikko group have been closely working together to develop more efficient foundation construction options. The large-scale 3D printing production of low-carbon concrete is a more efficient, fast, cheaper, and sustainable type of construction. They aim to optimize the construction of electricity transport by boosting efficiency and productivity. They designed foundations that consume 75% less material for construction and 25% material is sufficient to obtain structural strength.

Mighty Buildings (California – based 3D manufacturers)

Mighty Buildings is a California-based 3D manufacturing company that aims to create carbon-less construction by the year 2028. The company strives to create sustainable construction with modern technology utilization (3D Printing). The 3D building manufacturing group has taken 3d printing of residences with innovative materials to the next level.

a. Mighty Buildings + Fortera (Innovative Low Carbon concrete)

Location: California, United States

Project collaboration: Mighty Buildings + Fortera

Project: Innovative Low Carbon Concrete development

Mighty Buildings and Fortera have collaborated to develop an innovative cement that helps reduce carbon emissions by 60 percent. The negative impact of construction on the environment can be reduced, by replacing traditional concrete with Low carbon concrete to reduce its carbon footprint. The utilization of sustainable materials in construction is safer for the future.

b. Mighty Buildings + Palari Group (Community homes – Palm Spring)

Location: Palm Springs, California

Project collaboration: Mighty Buildings + Palari Group

Project: Community housing in Palm Spring

Mighty Buildings in collaboration with the Palari group have designed a community housing (Consisting of 15 homes) located in Palm Springs. The residences were constructed to be efficient, sustainable, and have zero material waste utilizing Low carbon (Carbon free) levels in cement for the 3d printing process. The community project focuses on sustainability in terms of material usage and introducing features such as solar panels, water filtration systems, climate control, etc. The project utilizing 3d printing (Wit low carbon concrete material) helps produce zero waste during the construction process.

WASP Project

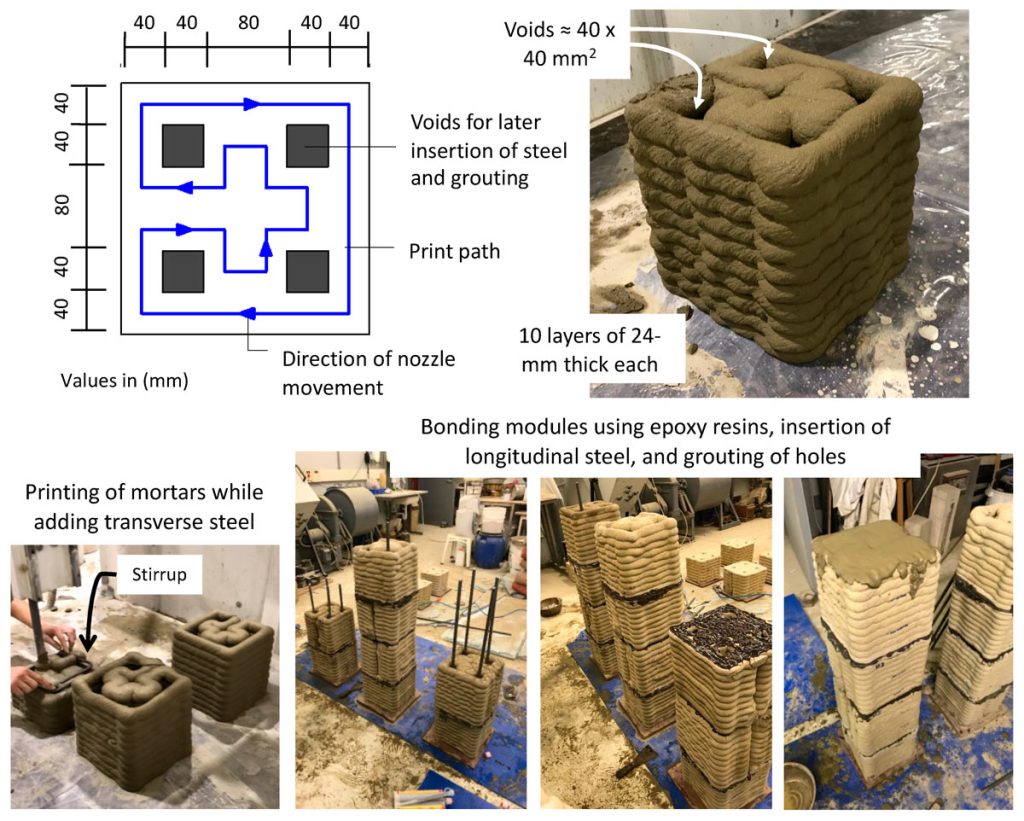

Project: Modular Printed Reinforced Concrete Beams (WAS Project)

WASP works with creating homes utilizing natural building materials. They experimented with 3D printing using concrete, they noticed that concrete produces a huge amount of CO2 emission. The WAS Project mainly focuses on creating structural elements for construction. The design of the project aims to eliminate redundant materials used for beam construction.

The project aims to reduce carbon emissions, by utilizing low-carbon concrete cement for 3d printing. The beams designed are being tested by the Department of Engineers, Architects, and Structural engineers, by testing their strength, and mechanical performance of the beam. The project is the best example to demonstrate sustainable and durable structural elements design by the use of 3d printing.

Construction waste – A Global issue that persists

Worldwide construction waste at present accounts for more than 1 billion tons each year. Construction, Demolition, and Renovation are the primary sources of waste generation in the construction industry. Waste from the construction industry is harmful to the environment, as it is responsible for land pollution (Dumping) and hazardous waste materials that affect health and the environment. Recycling construction waste is an important process that could help reduce waste accumulation. Some of the main sources of construction waste accumulation;

a. Material handling on site

b. Material residue during and after the construction process

c. Procurement source

d. Demolition process (During construction or to bring down an entire structure)

3D printing utilizing Low carbon concrete for the construction process has several benefits. The material helps reduce the amount of waste produced by the 3D printing process. It also reduces the cost and the CO2 emissions using low carbon-containing concrete. Low-carbon concrete 3d printing is the future of sustainable construction since it utilizes the least number of materials and a faster construction process.

Concrete 3D printing technology is the future for CO2 emission-reduced, efficient and sustainable construction process.3D printing is the future of construction which brings new possibilities to technology and designs. With the success of projects like Hyperion collaboration, WAS Project, and other manufacturing companies, the carbon footprint can be reduced considerably in the future.