Countries around the world struggling with the cost of living and the climate crisis have started to look for innovative and cost-effective solutions. One of these solutions that has experienced rapid growth in recent years is 3D printing technology. Once limited to prototyping, 3D printing is now widely used across industries such as automotive, manufacturing, supply chain, and construction.

With its ability to create complex structures, 3D printing is increasingly becoming part of the built environment. With the ability to create three-dimensional objects by adding material layer by layer, 3D technology can now print giant structures.

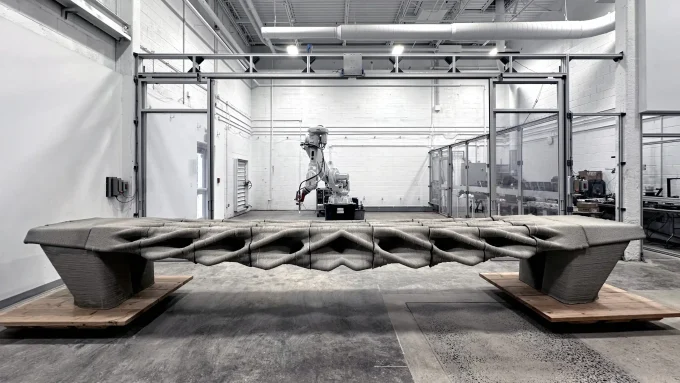

Originating in the 1970s, 3D printing involves the process of creating a physical object layer by layer from a digital model. Having found its place in architecture as well, 3D printing enables the automated production of construction elements, or even entire buildings, using a 3D printer. Today, the construction industry employs various types of 3D printing technologies, including robotic arm extruders, sand printers, and gantry systems. If the right conditions are met, 3D printers can be used in the construction of buildings and small structures, including printed buildings, micro houses, bridges, and stairs.

Most of the information needed for this technology to work in construction comes from the design process. Using a CAD or BIM program, the 3D printer receives the data it needs to print and begins layering material according to the instructions. This can be done with a variety of materials, the most common being concrete, geopolymers, fiber, and sand mixtures. This method not only reduces the need for manual labor but also enables low-cost production. With 3D technology, which provides easy production for complex geometries, construction components can be produced in a few hours; thus, the production and construction process is accelerated. By using only the required amount of material needed for each element, 3D printing minimizes material waste, making it an environmentally friendly solution.

3D printing technology, which allows the construction of structures that serve different purposes around the world and can reach meters in height, continues to push the boundaries of the ACE sector. Here are the 10 tallest structures in the world created with 3D printing:

1. Tor Alva (The White Tower)

Location: Mullens, Switzerland

Architect: Michael Hansmeyer

Year: 2025

The world’s tallest 3D-printed structure, Tor Alva, stands 30 meters tall in total. Designed as an immersive performance space, the White Tower features a domed theater surrounded by a forest of filigree, branch-like columns. Led by the Origen Cultural Foundation and in collaboration with ETH Zurich, the tower revives the village against structural challenges while offering a performance space that combines architecture, culture, and science.

The load-bearing system consists of 32 3D-printed concrete columns. Each column is articulated with a bold array of forms and intricate ornamentation on multiple scales, giving the structure a mysterious, almost otherworldly presence. The first eight columns of the lower level were 3D-printed at ETH Zurich using a robot that extruded soft concrete into multilayered printing paths, producing a series of joint-based, twisted hollow columns for the White Tower. While 3D printed architecture does not require any framework, the necessary steel reinforcement was installed during the robotic manufacturing process.

Soft concrete emerged as the base ingredient, and as the robot extruded thin layers of soft concrete through a nozzle, it instinctively guided itself to create geometric, hollow columns until it reached a certain height. The material, which was soft concrete, was malleable enough to bond to form homogeneous components. Once it hardened, which it did quite quickly, it supported successive fresh layer extrusions. Completed in approximately 900 hours of printing, Tor Alva incorporates a total of 232 3D-printed concrete elements and 104 prefabricated concrete components.

2. La Tour

Location: Bruay-sur-l’Escaut, France

The Tower in Bruay-sur-l’Escaut, Hauts-de-France, is one of the tallest 3D printed structures in the world, with an impressive height of 14.21 meters and a surface area of 450 m². A historic achievement in the field of 3D concrete printing, this tower is the result of Construction-3D’s collaboration with Sika. As a model of sustainability and innovation, the use of 3D printing in the project significantly reduced construction waste and optimized resource usage, thereby lowering the building’s overall carbon footprint. The ground floor of the structure, which has a total of 3 floors, is a showroom, while the upper floors are reserved for residential use.

Printed using the MaxiPrinter developed by Constructions 3D, the tower utilized Sikacrete®-733 as its primary material. Known for its strength and durability, Sikacrete-733 3D played an important role in the realization of this large-scale structure. This single-component, fiber-reinforced micro-concrete, used as a fluid, cement-based ink for 3D printing robots, offers an extended open time and a reduced environmental impact, making it ideal for sustainable construction.

3. WinSun 3D-Printed Apartment:

Location: Suzhou, China

Design & Build: WinSun Decoration Design Engineering Co.

Year: 2015

The 1,100 m², 6-story apartment building is one of the world’s tallest 3D-printed structures. Designed to reduce construction costs and promote sustainability, the project integrates 3D printing into the residential sector. Using a machine that is 20 feet high, 33 feet wide, and 132 feet long, the design team started with a basic CAD drawing and transferred it to a massive 3D printer that can produce the structure piece by piece using a specially formulated and patented ink.

Containing construction waste such as concrete, fiberglass, sand, and a special hardening agent that is self-insulating and resistant to strong earthquakes, the ink is one of the best ways to recycle common building materials. Containing construction waste such as concrete, fiberglass, sand, and a special hardening agent that is self-insulating and resistant to strong earthquakes, the ink is one of the best ways to recycle common building materials. The company then inserted insulation, beam and column reinforcements, and steel reinforcements into the walls, leaving space for plumbing, windows, and doors.

4. Wave House

Location: Heidelberg, Germany

Architect: SVV Architekten

Year: 2023

At 9 meters tall, Wave House is one of the world’s tallest 3D-printed buildings and is a data center. The centerpiece of the world’s first use of 3D printing technology in industrial construction combines organic architecture with digital fabrication, with its curved, undulating facades. The Wave House project was led by Mense-Korte ingenieure + architekten, a pioneering firm in Germany specializing in 3D printing applied to construction.

The Wave House, covering an area of 600 m², was printed using a COBOD BOD2 printer and was completed in 140 hours with just two workers. This equates to a productivity rate of approximately 4 square meters per hour, highlighting the rapid deployment capabilities of 3D construction printing technology. The material used is 3D printed concrete produced by Heidelberg Materials, known for its 100% recyclability and easy dismantling, thus promoting a circular approach to construction.

Compared to pure cement, this printed concrete achieves around a 55% reduction in CO₂ emissions. It is also easily pumpable and demonstrates excellent extrusion properties, making it ideal for sustainable, large-scale construction.

5. 3D-Printed Canal House

Location: Amsterdam-Noord, Netherlands

Architect: DUS Architects

Year: 2013

3D Printed Canal House, a research and design project exploring the application of 3D printing technology in architecture, is a modern interpretation of traditional Amsterdam canal houses. The 3D printer that made the project possible, KamerMaker, can print building parts up to 2x2x3.5 meters high from hotmelt, a bioplastic mixture that is 75% vegetable oil. The printed parts are then stacked and connected to form structural elements, which can be customized based on user preferences and functional requirements.

The ecosystem includes customization and engineering software, bio-based printing materials, and a variety of innovative XL FDM 3D printers capable of printing structural elements up to 5 m high. The prototype structure, covering 700 square meters, includes workshop spaces, XL 3D printing facilities, a café, and an exhibition area, demonstrating the potential for on-site, sustainable, and adaptable architectural production.

6. Tecla House

Location: Massa Lombarda, Italy

Architect: Mario Cucinella

Year: 2021

One of the tallest structures ever created with 3D printing, at around 4.2 meters tall, Tecla House is the first residential prototype built entirely with 3D printing technology using local soil, water, rice husk fiber, and natural binders. The name “Tecla” is a fusion of “Technology” and “Clay,” referencing the ever-evolving city of Tecla from Italo Calvino’s Invisible Cities. A project with almost zero emissions, the Tecla House’s frame and the use of entirely local materials allow for the reduction of waste and scrap.

Tecla is a combination of two continuous elements culminating in two circular roof windows through a sinuous and continuous sinus curve, which transmits ‘zenith light’. Giving life to an organic and visually consistent design, this house of approximately 60m² consists of a living area with a kitchen and a night area with services. The furniture, partly printed from local soil and integrated into the raw soil structure, and partly designed to be recycled or reused, reflects the philosophy of a circular house model.

The project, developed in collaboration with WASP (World’s Advanced Saving Project), addresses the need for sustainable, “0 km” green housing. TECLA uses two synchronized printing arms at the same time, thanks to software that can optimize movements, prevent collisions, and ensure smooth operation. Each printer unit has a printing area of 50 square meters, making it possible to build independent housing modules in a few days. With the Crane WASP printer, TECLA printed 350 sheets in a total of 200 hours, and a total extrusion of 150 km was made.

7. PERI: 3D-Printed Multi-Family Housing Project:

Location: Lünen, Germany

Year: 2023

The 3-storey residential project in Lünen, Germany, is one of the tallest 3D printed structures in the world. It consists of a 420 m² apartment building with six residential units that demonstrate how 3D printing can be used to create affordable housing. The first two floors were constructed using 3D-printed concrete, while the top floor was built using a traditional timber-hybrid system—an innovative approach that enhances both structural stability and construction efficiency.

The COBOD International BOD2 3D printer was used for the house, which was printed using a building material from Heidelberg Materials. The project, where the total pure printing time took 118 hours, designed the apartments functionally to test comfortable living spaces. 3D printing layer traces were left in the interiors as an aesthetic element.

8. 3D Printing Villa Project in Riyadh

Location: Riyadh, Saudi Arabia

A 3D printed villa project, part of Dar Al Arkan’s 2021 collaboration with COBOD, is one of the world’s tallest 3D printed structures. Part of Saudi Arabia’s Vision 2030, the 345 m² villa rises to a total of 9.9 meters with its three floors. The first floor of the house is a 130 m² area with a large lounge area containing living areas, a kitchen, and 2 toilets. The second floor, measuring 140 m², has 3 bedrooms, 2 bathrooms, a living room, and a balcony, while the third floor is a roof annex with a maid’s room, a multipurpose hall, and a laundry room.

Remarkably, the structure was printed without any tents or shading, even under extreme desert conditions during the hot months of August and September, when temperatures exceeded 40°C. The project utilized locally sourced materials through Cemex and COBOD’s d.fab solution, which enabled up to 99% of the concrete components to be supplied locally, significantly reducing printing material costs. The villa, built with COBOD’s BOD2 printer, is equipped with smart home technologies.

9. Office of the Future

Location: Dubai, United Arab Emirates

Architect: Killa Design

Year: 2016

The world’s first fully functional and permanently occupied 3D printed office building, Office of Future, is one of the world’s tallest 3D printed structures at 6 meters high. Now serving as the headquarters of the Dubai Future Foundation, the building also functions as an exhibition space and incubator for emerging technologies in the region. Spread around a tree-shaded café courtyard, the structure includes a partnership lounge and gallery for exhibitions, workshops, and events, a flexible space for design work, and private meeting rooms for quiet work. A series of strategic openings allow natural daylight to penetrate deep into the space, maintaining a visual and spatial connection with the outdoors.

The entire building was produced using a 20-foot-high, 120-foot-long, and 40-foot-wide 3D printer using additive concrete printing techniques. Nanomaterials in the concrete mixture of the office, which was printed layer by layer, increased the durability of the structure. The project, which was printed as prefabricated panels and assembled on site, took a total of 17 days to print. The Office of the Future was completed in a total of 3 months, including work on building services, interiors, and landscaping. Thanks to 3D printing, labor costs were reduced by more than 50% compared to conventional buildings of similar size, while waste on site was minimized.

10. Qatari 3D-Printed Tower

Location: Doha Expo 2023, Qatar

Year:2023

With its 30-degree inclined and interrupted circular structure, the Qatari 3D Printing Tower has a design that pushes the boundaries of 3D printing technology. The tower, which spreads over an area of 170 m², is one of the tallest 3D-printed structures in the world, with a height of 12.4 meters. Constructed as an active contribution to Expo 2023 Doha, an event aligned with Qatar National Vision 2030 and focused on sustainability and innovation, the tower consists of 75 individually 3D-printed components. The structure, which holds the title of the most free-standing 3D printed concrete structure, consists of 10 layers of eight or nine blocks each. Each concrete element was printed separately, and the material was printed only where necessary for durability.

Leave a comment