Experiments give clarity and enthusiasm to configure futuristic ideas. SOM (Skidmore, Owings & Merrill) envisaged a pavilion with a curving concrete roof balanced atop two concrete columns using a method that could diminish the carbon footprint in high-rise concrete buildings.

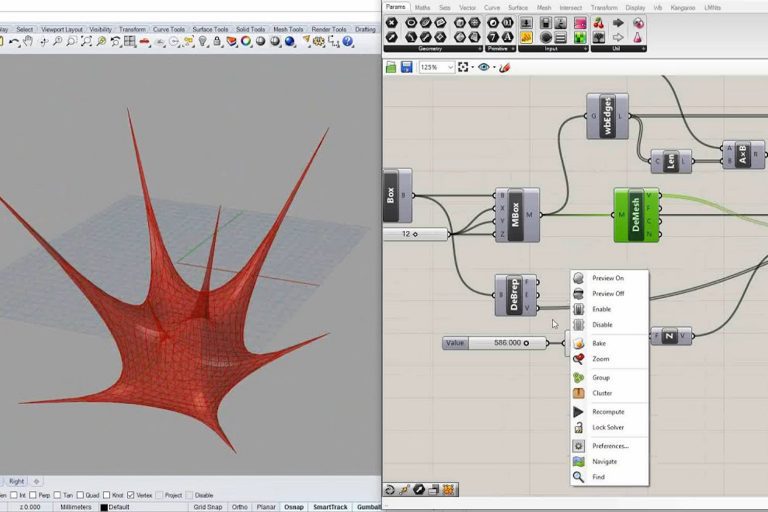

The Stereoform concrete slab pavilion is a prototype of a single-storey concrete bay found in high-rise buildings. With the integration of robotic fabrication composed by Odico, argues the novel idea to be more sustainable than traditional construction methods, and could reduce its carbon footprint.

SOM aims to topple the dislike of concrete by experts and show how we can drastically alter the carbon footprint of concrete using these kinds of methods. The designers founded sweeping fluctuations as much as 40 to 60 per cent of its carbon footprint.

Scott Duncan, SOM design partner said that “This pavilion demonstrates the exciting potential for design, technology, and building collaborations to make a significant impact on the way we approach large-scale construction. The design of Stereoform Slab expresses a more intelligent allocation of material, evocative of forms in nature,” he added.

The design and its approach can pave the way to envisage an innovative and sustainable future of design and living in the built environment. SOM added that the process requires unpretentious methods and can be implemented with ease. The curvature was robotically enwrapped using reusable Expanded Polystyrene (EPS), which can mould and shape the slab into arches, which lessen the amount of material and waste. The team calculated a 20 per cent carbon reduction as well as material compared to conventional mechanics.

“The robotic formwork fits within a more conventional horizontal casting system that makes its use relatively similar to current practices – reducing the learning curve for adoption by those constructing in the field,” said SOM. Developing formwork systems that afford added complexity without adversely impacting common construction processes will yield smarter and more sustainable forms in concrete. Stereoform Slab is an exploration of this issue, understanding that it is imperative we more broadly rethink more conventional building types – and their construction.”

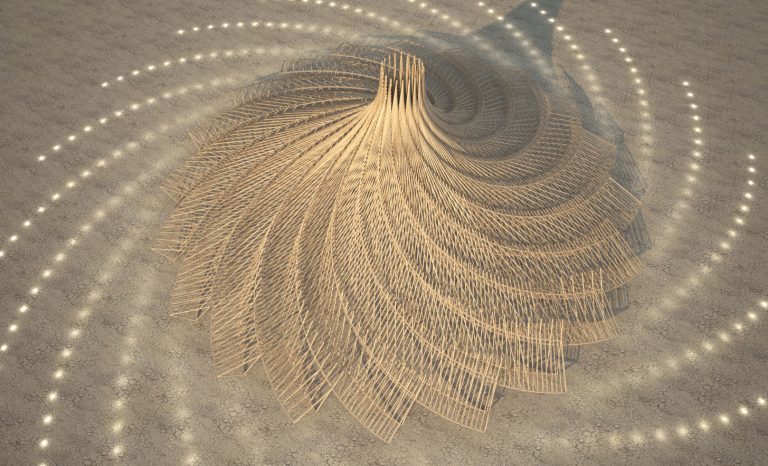

During the evenings, coloured lights are flashed onto the structure from the ground, illuminating the concrete pillars and painting a rainbow-like display below the roof. A unified seat is abutted along, consisting of a single volume and crafted using white foam mould and robotic arm movement, thus showcasing more sustainable practices for concrete construction.

SOM’s Stereoform Slab and the Conversation Bench will weave urban interventions in the city that are eloping in new methods of digital fabrication, construction and architectural design. The techniques and craft symbiotically synchronize to establish a temporary space for civic rendezvous.