Ghost Tectonics is an experimental architectural pavilion designed by Roland Snooks and developed by the RMIT Architecture | Tectonic Formation Lab, that integrates large-scale 3D printing with intricate carbon fibre reinforcement. With research in collaboration with Boeing, the project represents a significant advancement in robotic fabrication and composite construction by incorporating polymer 3D printing with Tailored Fibre Placement (TFP), to enable the creation of lightweight, patterned architectural skins.

Designed through generative AI, an intricate pattern of carbon fibre that aligns with structural forces, is laminated onto translucent 3D printed shells. This computational fibre logic results in an intricately patterned shell that is both visually expressive and structurally efficient—a new model for integrating performance and ornamentation through robotic making. Ghost Tectonics renders visible the unseen forces shaping structure and form.

Hybrid Fabrication: 3D Printing Meets Carbon Fibre Tailoring

The RMIT Architecture | Tectonic Formation Lab, in conjunction with Boeing, has developed an innovative process for integrating tailored carbon fibre and 3D printing. Tailored Fibre Placement (TFP) is a high-tech embroidery technique that is used to precisely position continuous carbon fibres onto a glass fibre substrate. These composite preforms, produced by IPF and Hightex, can be designed with optimal strength-to-weight ratios by placing fibres in the direction of structural loads.

Fibre composites are extremely strong and lightweight but traditionally depend on costly and wasteful mould-based fabrication processes that limit design freedom and geometrical variation. Conversely, 3D printing allows for the creation of bespoke, geometrically complex forms without the need for moulds or formwork—a key factor in enabling mass-customisation and reducing material waste. However, polymers alone lack the structural capacity required for architectural applications.

Ghost Tectonics marks the first architectural demonstration of this hybrid fabrication technique of printing tailored fibre composites. The 3D printed plastic shell acts as a substrate—what the lab describes as “sacrificial formwork”—onto which structural carbon fibre is laminated. This reverses the typical logic of construction, where a structural system is clad with surface, and opens up new tectonic possibilities. This novel approach enables the construction of geometrically intricate, materially efficient, and visually rich forms—high-performance architecture where structure and ornament are fundamentally intertwined.

“Ghost Tectonics collapses the boundary between ornament and structure—carbon fibre becomes both pattern and performance,” says Roland Snooks. “We’re using AI and robotic fabrication to embed an intricate structural logic directly into the surface of architecture. By combining 3D printing and tailored fibre reinforcement, we’re opening up new aesthetic and tectonic design possibilities for lightweight, materially intelligent structures.”

Generative Process: Agents, AI, and Structural Performance

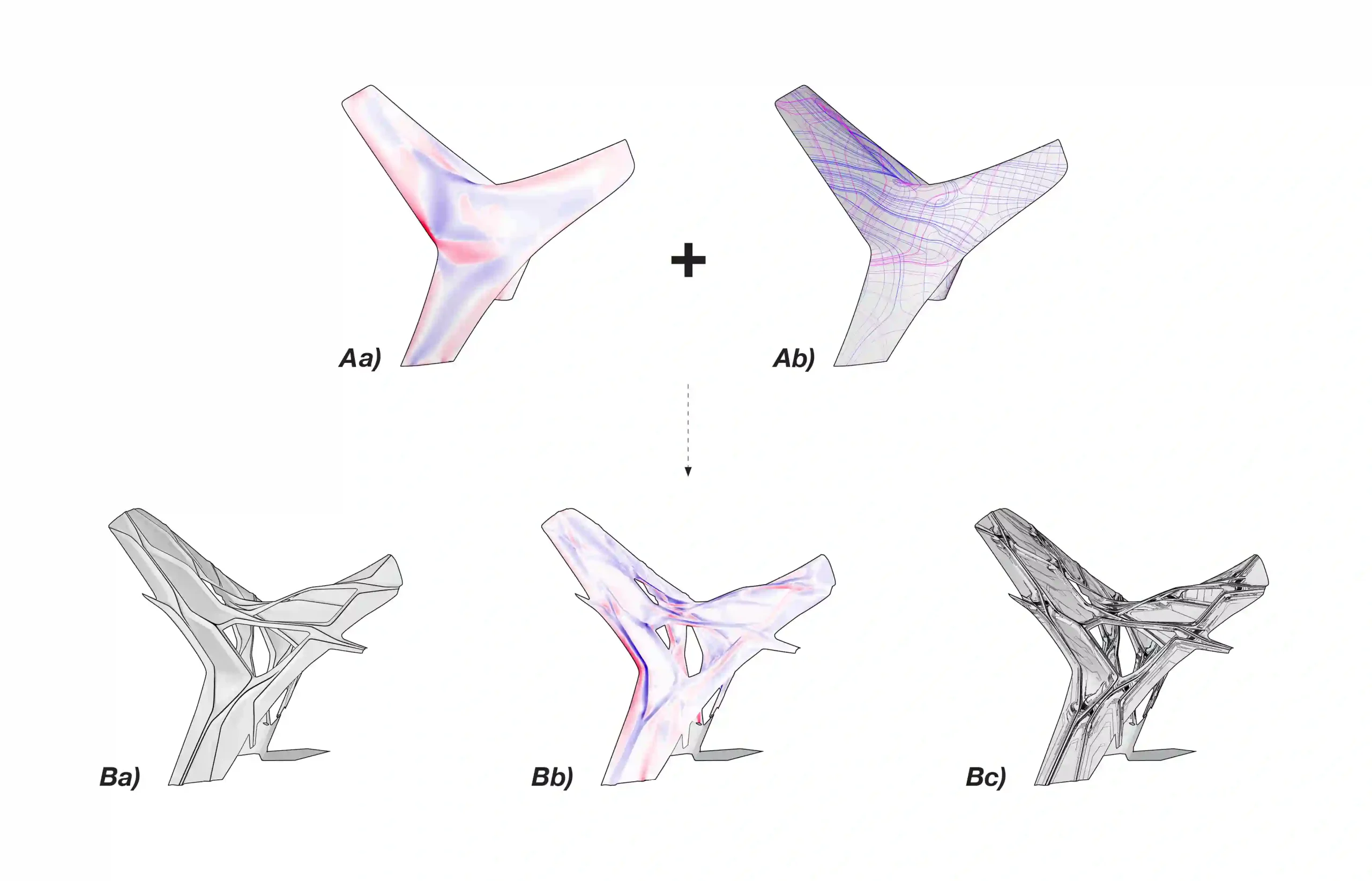

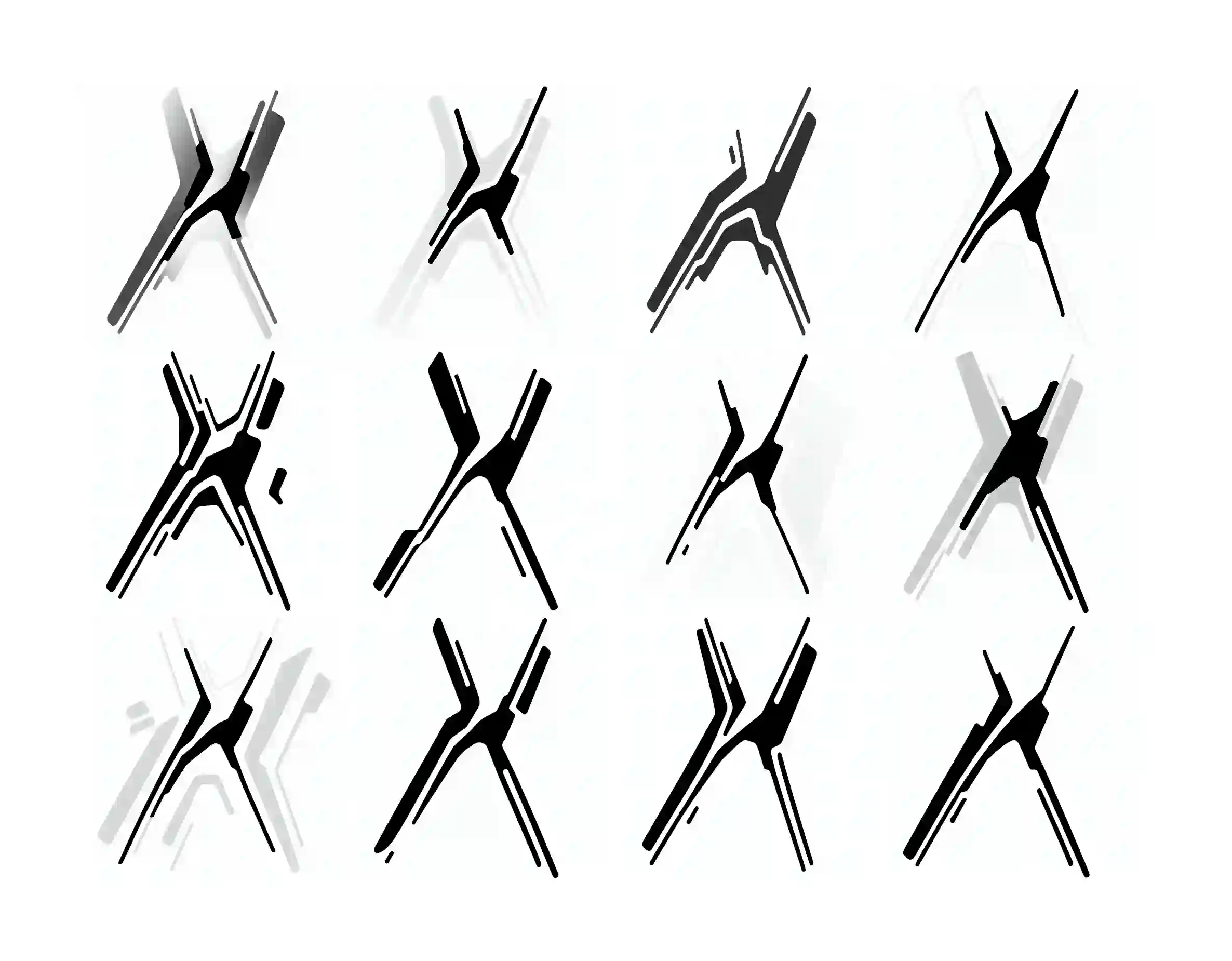

The pavilion’s form was designed through an agent-based generative approach, where swarms of computational agents interact to create intricate, emergent spatial forms. The carbon fibre patterning was created through a generative AI process that responds directly to Finite Element Analysis (FEA). The system interprets structural stress data to generate fibre paths aligned with force flows, resulting in a visually intricate, structurally optimised reinforcement strategy.

Together, these systems produce a layered design logic: geometry generated through computational emergence, and structure inscribed through machine-placed fibre, guided by both performance and aesthetics.

An Architectural Prototype for Customised, High-Performance Structures

Beyond its role as a design object, Ghost Tectonics is a prototype for a new approach to construction—one that enables mass-customised, structurally efficient, and materially expressive forms created through robotic automation without the overhead of moulds or component standardisation.

Its relevance spans beyond architecture, intersecting with fields like aerospace, industrial design, and composite manufacturing. In collaboration with Boeing, the project opens a dialogue between architectural design and aerospace innovation, where structural performance, material lightness, and formal freedom converge.

About the Tectonic Formation Lab

The RMIT Architecture | Tectonic Formation Lab, led by Roland Snooks, is a research group exploring the design implications of emerging technologies through advanced computation and robotic fabrication. The lab focuses on the development of new design methodologies, such as multi-agent systems and generative AI, in tandem with innovative fabrication techniques like robotic 3D printing and composite construction.

Through collaborations with industry partners like Boeing, the lab tests architectural prototypes that challenge conventional construction models and speculate on new tectonic paradigms.

Project Credits

Ghost Tectonics, 2025

RMIT Architecture | Tectonic Formation Lab

Design: Roland Snooks

Research: Alan ‘Ho Kyeong’ Kim, Roland Snooks, Phillip Crothers, Stuart Bateman.

Project Development: Alan ‘Ho Kyeong’ Kim, Mandisa Sarker, Ryan Justice, Patrick Green, Steffi Sum Yee Li, Matthew Handoko, He Huang, Ashlin Cam.

TFP Production (IPF and Hightex): Axel Spickenheuer, Dirk Feltin, Stefan Friebe.

Fabrication and Assembly Assistants (RMIT University School or Architecture and Urban Design): Ho Yeon Yoo, Yuanyuan Sun, Julien Finti, Ryan Justice, Hussain Asghar, Rui Shane Song, Jessica Thomson, Lachlan Buckley, Celine Blanco, Duc Vu, Dale Manandic, Jackson Le, Jatan Shah, Xingyu Hao, Zhen Zhang, Ned Daniels, Rui Tong Li, Shirin Killinc.

RMIT STEM Workshop Team: Paul Muscat, Nav Lokugalappaththi, Michael Delaney.

Developed and supported by:

RMIT University, Boeing Aerostructures Australia, Hightex Dresden, IPF – Leibniz-Institut für Polymerforschung Dresden

The project was developed through the RMIT-Boeing Alliance.

Leave a comment