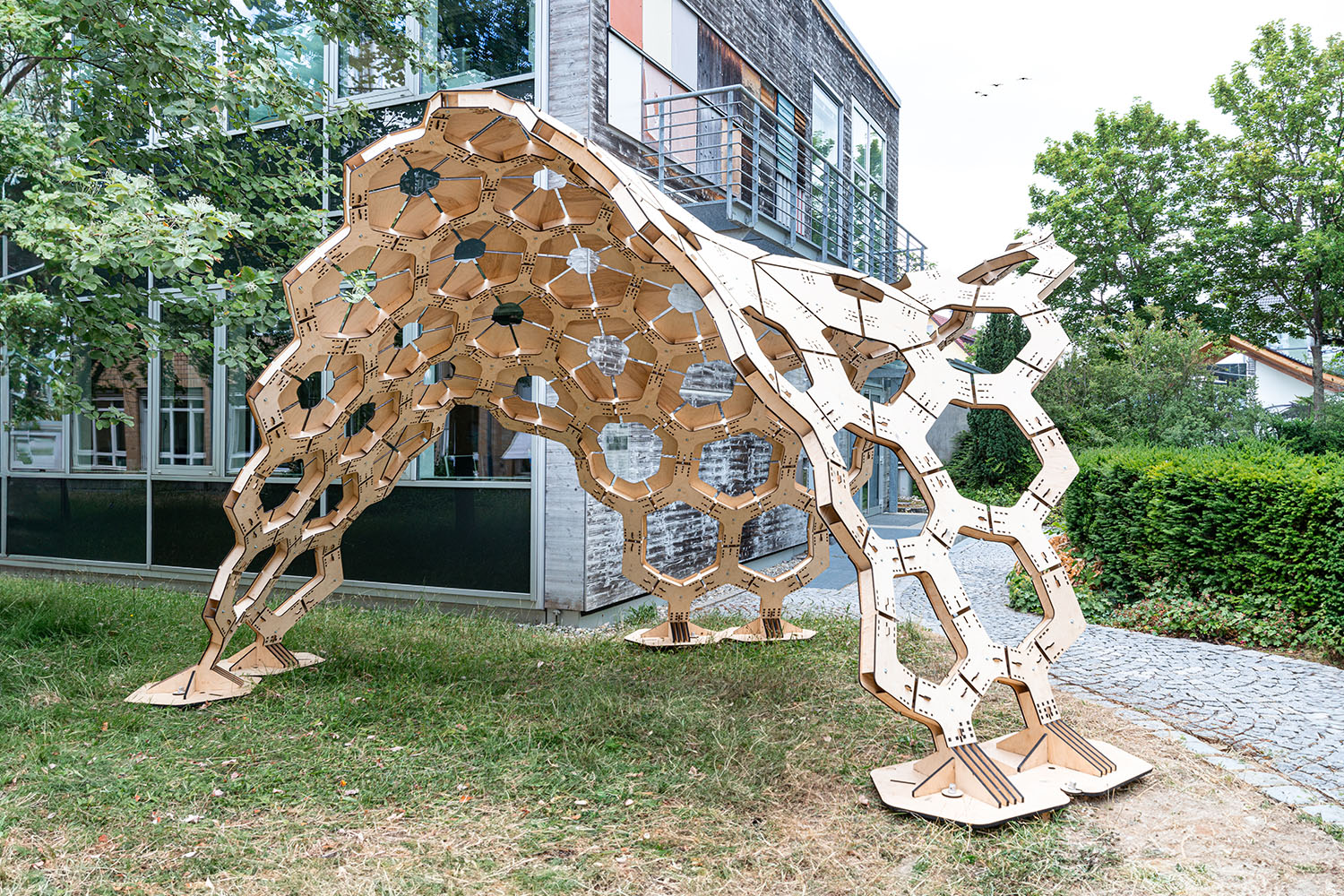

Carapacks Pavilion emerged as the outcome of a design-build initiative that spanned several semesters at the Biberach University Faculty of Architecture. A concept was formulated by a group comprising Simon Vorhammer, Dr. Jonas Schikore, Dr. Christina Jeschke, and David Ott, with the intention of utilizing double-shell interlocking systems to implement arbitrarily curved freeform surfaces. The hexagonal system is distinguished by the absence of curvature and torsion in all of its components, as well as the possession of perpendicular cut edges. This guarantees production that is both efficient and economical through the use of 2.5-axis CNC laser or water jet cutting technology.

The assembly procedure is uncomplicated and can be executed by proficient non-professionals without requiring the use of substantial apparatus. By incorporating labels and positions into the components, the geometrically distinct panels can be assembled without the requirement of blueprints—a process akin to solving a conundrum. The planarity permits layering that conserves space. To illustrate, the construction study presented below comprises complete components that can be accommodated within the compartments of two station wagons.

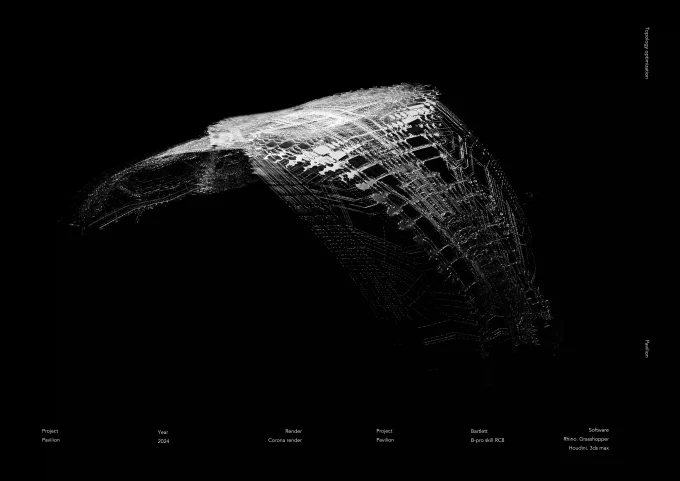

The digital parametric model enables the specification of a multitude of input parameters, including segment size, overall shape, degree of enclosure, and shell thickness. This facilitates the production of manufacturing-ready packages for an extensive variety of initial geometries in an almost instantaneous manner.

As stated by the architects, a 1:1 scale pavilion was constructed on the university campus this summer to test the interlocking mechanism. The structure was composed of 592 wooden elements. Following an estimated six-week period, the structure will be dismantled and subsequently reassembled in a different location on the campus the following year.

The applicability of the system extends beyond timber pavilions to encompass roofs and facades as well. In addition to wood treatments, material durability can be ensured by selecting wood suitable for outdoor use or by employing alternative weather-resistant sheet materials.

Project Info

Project Name: Carapacks Pavilion

Concept, Planning, and Manufacturing: Prof. i. Vertr. Simon Vorhammer, Prof. i. Vertr. Dr. Ing. Jonas Schikore, Prof. Dr. Christina Jeschke, David Ott

Assembly: Alexandra Palesch, Jürgen Pröll, Fabienne Neuf, Katy Guth, Kira Kortländer, Yusuf Cosgun, Lara Wingenfeld, Florian Gärtner, Berkay Mutlu

Leave a comment