Can products grow and decompose as ecosystems? Can we design the life cycles of consumer goods to borrow matter and energy from Nature and return them upon obsolescence?

OXMAN presents a revolutionary class of biologically programmed, computationally grown, and robotically manufactured shoes and textiles that give biodegradable bioplastics the design that their biology deserves.

Made entirely of polyhydroxyalkanoates (PHAs), a bacterially produced thermoplastic polymer, the mono-material Oᵒ platform enables the design and digital fabrication of apparel items, such as shoes and textiles, that exhibit a range of physical properties, functions, and end-of-life trajectories.

“Since PHA-producing bacteria can utilize a variety of feedstocks the products designed with them can lead to a range of carbon footprints. In addition, we process PHAs using various digital fabrication methods —from 3D printing to hot melt spinning and knitting. Such high levels of versatility, achieved through design tunability across design stages and media—production, processability, and programmable decomposition— are at the core of Oᵒ’s designs and platform technology.“

The Oᵒ platform embodies a world where design and digital fabrication are vertically integrated with biomaterial production systems to achieve programmable decomposition of goods designed for the mutual benefit of ecosystems and the environments around them.

If you’re interested in 3D-printing shoes, our footwear design workshops at PAACADEMY could be a great fit for you! The Footwear Design Bundle combines two workshops on parametric design and 3D printing, teaching advanced techniques for creating innovative, high-performance footwear.

100% biodegradable. 0% microplastics. 0% use of landfills.

“We present the first-ever Nature-centric shoe and apparel line, made with 100% biodegradable PHAs. Designed for sustainability, our products break down in most natural environments, leaving zero microplastics behind.“

PHA, essentially a bacterial fat, represents a high-calorie food source for certain bacteria and fungi. As a carbon rich food source, it can drive increased microbial growth in the soil ecosystems it enters and unbalance the ecosystem. The challenge therefore is to figure out how to manage the carbon contained in the PHA once the material enters, and then leaves the hands of consumers.

The circular nature of O°—being produced and consumed by the same class of organisms—points to a future where products biodegrading into microorganisms can nourish the soil from which they originate; a future where products can reincarnate into plant matter, and vice versa.

O° aims to remove the complexity involved in the fabrication of objects by tuning a single and versatile mono-material class known for its biodegradability in ambient conditions and its ability to be produced from feedstocks such as atmospheric carbon dioxide or methane².

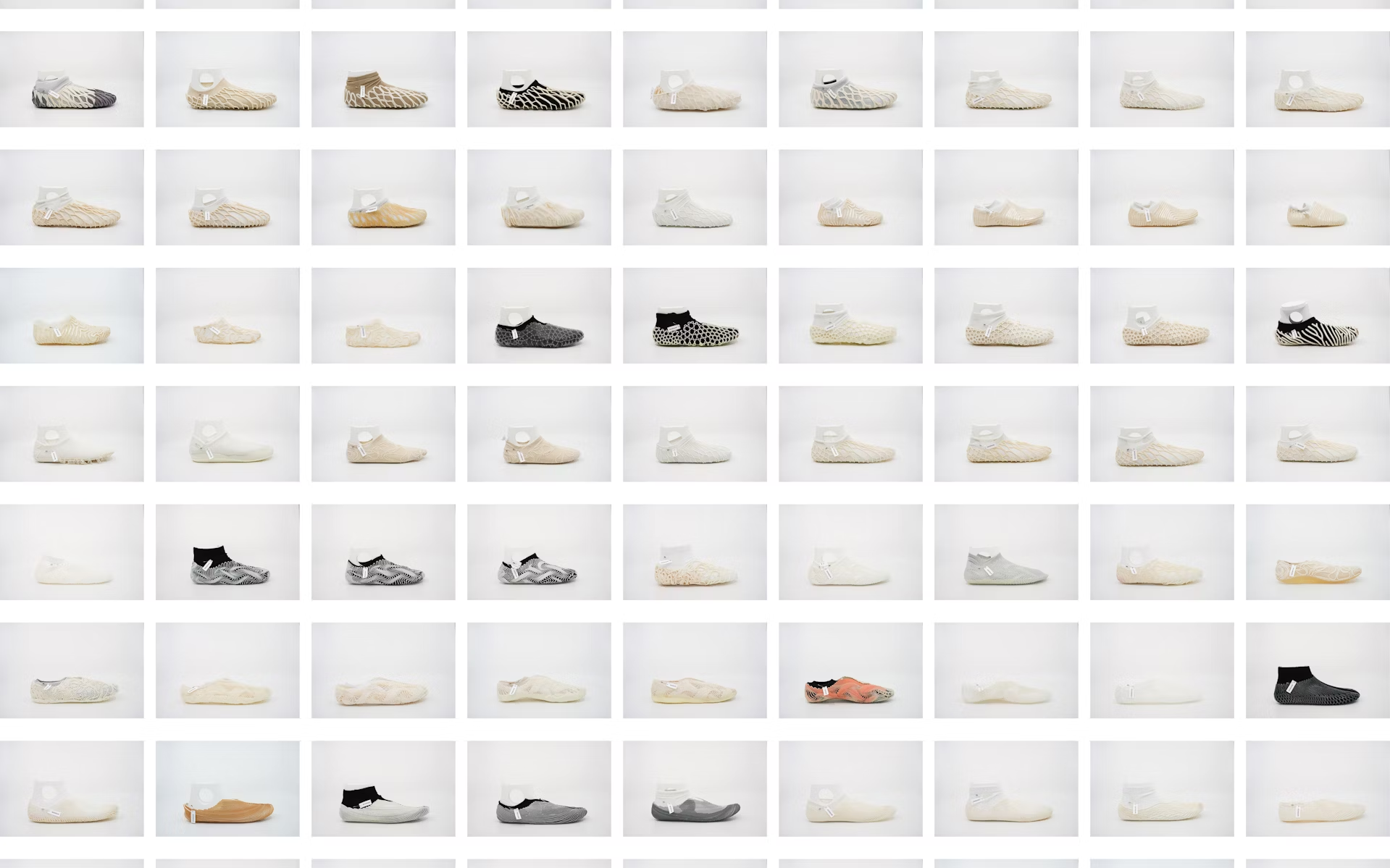

The O° shoe is not a single shoe design but a design language and potential world of shoes made from PHA. It embodies the versatility of PHAs by incorporating them as knitted textiles and tough 3D printed elements in precise designs informed by the kinetics of human motion and requiring strict standards for comfort, robustness, and aesthetics.

At the heart of each shoe is a unifying base layer of a knitted sock. Given the shoe’s individual intent (e.g., ballet slipper, sneaker), outer layers are printed on the knitted textile to provide specific functionalities such as reinforcement, cushioning, strength, and pliability. The versatility and automation built into the O° platform technologies enable rapid iterations and an accelerated development process from design to production.

Disposable products that come from and return to microorganisms

PHA, essentially a bacterial fat, represents a high-calorie food source for certain bacteria and fungi. As a carbon rich food source, it can drive increased microbial growth in the soil ecosystems it enters and unbalance the ecosystem. The challenge therefore is to figure out how to manage the carbon contained in the PHA once the material enters, and then leaves the hands of consumers.

The circular nature of O°—being produced and consumed by the same class of organisms—points to a future where products biodegrading into microorganisms can nourish the soil from which they originate; a future where products can reincarnate into plant matter, and vice versa.

Facts & Figures:

- Tons of garments that end up discarded annually: 92M

- Number of materials used to create a traditional shoe: 40

- Range of “Forever Chemicals” in a traditional shoe: 33 – 4,200

All images and videos courtesy of OXMAN.

The project description is provided by OXMAN.

Leave a comment