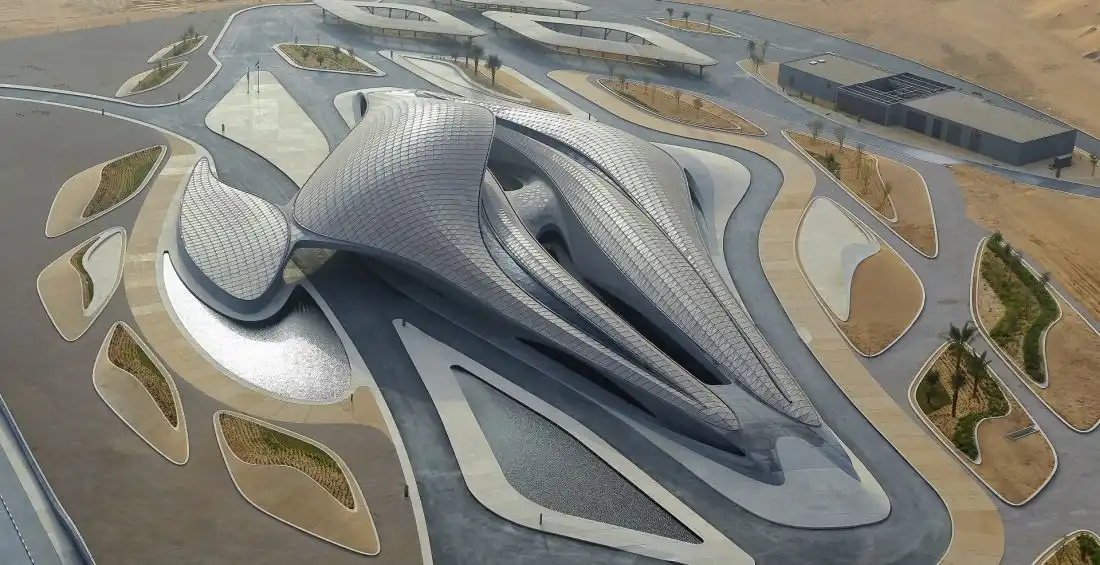

In the expanse of Sharjah’s Al Sajaa Desert, Zaha Hadid Architects implanted the Beeah Group Headquarters as nothing less than an oasis in the middle of the desert featuring sand dune-like structures and water elements. The trailblazing design firm has again proved its brilliance in the Beeah headquarters design, formulating the blueprint and setting the bar high for future workplace designs, embedding sustainability and digitalization, the two pillars of the Beeah Group, pioneering in waste management and recycling, clean energy, environmental consulting, education, and green mobility.

Beeah Headquarters was one of Dame Zaha Hadid’s last projects, still under construction when the legendary woman architect passed away. The Zaha Hadid Architects Team, the client, Al Futtaim Construction, and the other sub-contractors, Buro Happold, Atelier Ten, Lindner Steel and Glass, and the other parties have done justice to the work that the late Zaha Hadid left behind without tampering with her original vision for the project.

The headquarters of 9,000 square meters in a massive 93,000 square meters plot relies on a photovoltaic system for its energy needs, achieves net zero emission, maintains thermal comfort while still optimizing energy consumption, reduces water usage and minimizes material consumption in construction, integrating structural and architectural solutions. Subsequently, the project has been awarded the highest LEED Platinum certification and BREEAM Outstanding Rating.

Phantasmagoric Renders of the Beeah Headquarters Design that Speak Volumes

The mystic renderings produced with the help of a Norwegian firm MIR that surfaced on the internet display a series of dune-like structures amidst date palm trees surrounded by smoke and mist. These renderings capture in an image, the site conditions, the overall conceptual approach that the architects developed, and the concept’s response to the site – “a series of interconnecting ‘dunes’ orientated and shaped to optimize local climatic conditions.” The image of the phantasmagoric renders certainly mimics that of a mirage, but in reality, the headquarters is a fertile oasis in the desert at the mercy of sustainability and technological advancements.

More than just a Mirage, A Man-Made Oasis for the Beeah Group

Understanding each dune mentioned in the concept as a segment, featuring dips and ridges, with a streamlined body, and undulating form, the complete formal composition is the arrangement of these segments on the site leveraging the prevailing Shamal winds, from the Northwest.

Three segments or dune shaped, streamlined modules varying in size and form make up the form of this building, of which two primary dunes meet at the courtyard – an oasis, as called by the Architects and a smaller segment is attached to one of the primary dunes from the above but features a porte-cochère below. The idea of an oasis is further extended in the landscape design with water elements, vegetation, and smaller dune-shaped car parking shade structures.

From the ridge of the dune-shaped segment towards the periphery of the whole form, the roof blends into a façade and plummets down like rolling sand. One of the primary dunes features a concrete dome with openings on the windward side on the north, facilitating natural lighting.

Activities Thriving in the Beeah’s Spectrum of Spaces

The smaller dune on the far north houses a self-sufficient visitor’s center that can be accessed directly from the outside owing to Beeah’s philosophy of creating awareness and educating people about their pioneering sustainable ways of waste management. A long curved drop off road with a porte-cochère in the middle resides below the piece of roof that weaves the smaller dune with the primary one.

The entrance dune, out of the primary two dunes, features the semi-public zones, including an auditorium right at the entrance, the entrance lobby making a bold statement with the overhead concrete dome, a conference room, the research labs, and the department offices. The other primary dune hosts more private offices, administration spaces, and a private café for the employees with restricted entry. From the north to the south, there is a clear imaginary axis of the growing private nature of activities in the spaces.

The circulation within the interconnected primary dunes is governed by the interwoven courtyard that links them. Besides the spacious central lobby, the twisted aisles between the courtyard walls and the internal partition walls that wrap it allow for accessing the protected private office areas. The courtyard serves as a break-out space with soothing elements like water features, on top of filling up the interiors with diffused daylight and providing an opportunity for natural ventilation.

Putting the Pieces of the Beah Headquarters Together

Initially, the sweeping structure of the Beeah headquarters was planned to be constructed as a concrete shell. However, the structural and facade engineers intervened to change the initial plan to cut down on costs, time, CO2 emissions, and energy consumption, adhering to the ethos of the Beeah group, yet without sacrificing the originality of Zaha Hadid’s design.

The engineers with extensive expertise and previous experience in realizing geometrically intricate structures, came up with an absolute solution – a prefabricated steel structural frame holding the GFRC Panels in place as the enclosure to develop the sinuous structure of the headquarters. Thus, the façade which twists, turns, and unfurls, dancing to the voiceless rhythm of the winds initially conceived as a concrete shell, was developed as a steel structure clad with GFRC panels.

The solution sprang from the idea of splitting the complex structure into a series of components, separating pieces, and putting them back together. The design consisted of parallel structural steel ribs that were prefabricated off site, transported easily to the site, and assembled on site using established techniques and known tools. In addition, prefabricating the components allowed for timely calculation of costs and scheduling as well as guaranteed a risk-free reliable structural design.

Glass fiber reinforced concrete (GFRC) panels were chosen for the exterior cladding of the flowing roof surface as it is an eco-friendly material that passively enhances thermal comfort inside the building. Almost 4000 GFRC panels, each weighing over 100 kilograms, make up the intersecting white dunes that Zaha Hadid envisioned for the Beeah Group.

The project boasts stunning façade elements including a gigantic 650 square meters of sloping glass panels in the entrance lobby, dynamic triangulated warped linear ribbon facade, spectacular skylights on the cascading undulating roof, and bold vertically curved glass that defines the courtyard walls.

Understanding the intricacies of such complex geometries requires deep expertise—something PAACADEMY’s workshops offer through instructors from Zaha Hadid Architects, who share their design techniques, tools, and workflows.

Giving Life to the Concrete Dome in the Beeah Headquarters

However, the concrete dome in the entrance hall was an exception to the steel structure that the engineers proposed. The 23 meters long and 17 meters wide concrete dome in the entrance hall, soaring 15 meters high, was an architectural element of immense importance, forming the first impression when entering the premises of the project.

The construction of this humungous concrete shell was complex due to high expectations of exceptionally excellent concrete quality and a very low tolerance for joint patterns, anchor points, and screw heads. The shell was realized in phases with four formwork sections to tackle the complexity. The climate also posed a challenge, persuading the team to work at night on the dome for two months as temperatures during the day were extremely high.

The formwork for the shell was tailor-made to fit the recesses and unique arched form of the slab. Custom-made high quality curved plywood, Vario GT 24 system components, SLS heavy-duty Spindles, and SRU steel walers did their job as perfect formwork and load-bearing substructure.

How Sustainability and Digitalization are manifested in Beeah Headquarters Design?

Employing cutting-edge technologies and AI-integrated solutions, the Beeah Headquarters Design proves that today’s advanced technologies can optimize HVAC, electrical, and plumbing systems, optimizing energy and water consumption, reducing carbon emissions, and driving sustainability in built environments.

Leveraging automation software and AI technology, the Headquarters provides its employees and visitors an experience way ahead of its time, mimicking those in sci-fi movies with a virtual concierge with facial recognition attributes promoting a warm entry protocol, smart meeting rooms automatically sending the meeting minutes as emails to the participants, contactless pathways, especially safer in a post-covid era, and a companion app that automates the daily formalities like sending requests to the administration department.

But mainly it was the integration of AI in the building management system that elevated the sustainability prospects and opened up new possibilities for a digitalized smart building management system (BMS). Using a digital twin technology, creating a virtual model of the building, Beeah’s BMS collects qualitative and quantitative data on resources used, studies it, runs simulations, and makes the necessary changes, optimizing energy consumption to meet Beeah’s sustainability targets.

For instance, Beeah’s smart building management system synchronized with its HVAC systems achieves a desirable comfortable indoor temperature while maximizing energy efficiency and regulates the lighting and indoor temperature based on the number of occupants and times of the day.

Recycled grey water is used for irrigation of the vegetation in the landscape, minimizing water consumption. In addition to the form of the building, its orientation, and the position of glazed elements, Low-E glass was used to lessen solar gain and the high thermal mass allows for solar heat absorption in the day and heat dissipation in the night, reducing the cooling demand of the interiors.

Taking into account the harsh climate of the region, a huge chunk of energy is consumed by the air conditioning system. The building relies on operable facades allowing fresh air into the building during milder months, reducing the energy needed for artificial cooling. On the other hand, during the summer months, when air conditioning is unavoidable, an energy conservation strategy is used – the output heat from the chiller that is conventionally released into the atmosphere is channeled to pre-heat the domestic hot water supplies.

While the energy consumption is predicted to be reduced by 30% from baseline, electricity is generated on site with an array of solar panels, and the energy is stored in Tesla battery packs and from waste that would otherwise go into landfills, meeting the energy demands of the headquarters.

Most of the structural and cladding elements were manufactured in the UAE, owing to the architect’s and client’s commitment to sustainability and low carbon emission. Around 90% of the construction raw materials are locally sourced, including recycled concrete, aggregate, and steel, ensuring an ultra low carbon footprint.

A Desert Wonder | National Geographic MENA ©NatGeo MENA

“The headquarters is the latest milestone for Beeah Group as it continues to pioneer innovations for Sharjah and across the globe, establishing a base of operations for the group to diversify into new, future-critical industries,…With their new headquarters, BEEAH demonstrates how technology can scale sustainable impact and ultimately serve as a blueprint for tomorrow’s smart, sustainable cities,” said Zaha Hadid Architects.

Beeah Headquarters Project Details

Project Name: Zaha Hadid Architects (ZHA)

Client: BEEAH Group

Location: Al Saj’aa Industrial Area, Interchange 8, Sharjah, UAE

Photography: Hufton+Crow, PERI-GmbH, MIR|ZHA, Momentary Awe|Catalin Marin

Drawings: Zaha Hadid Architects

Leave a comment