Groundbreaking transformations are observed in the age of Industry 4.0 with respect to the building industry. Digitization has proven beneficial to the building industry, specifically through BIM models (Building Information Modeling). This digital transition applies to all phases and aspects of construction projects. Additive manufacturing, especially 3D printing, is a modern marvel. Recently, it has gained a lot of attention.

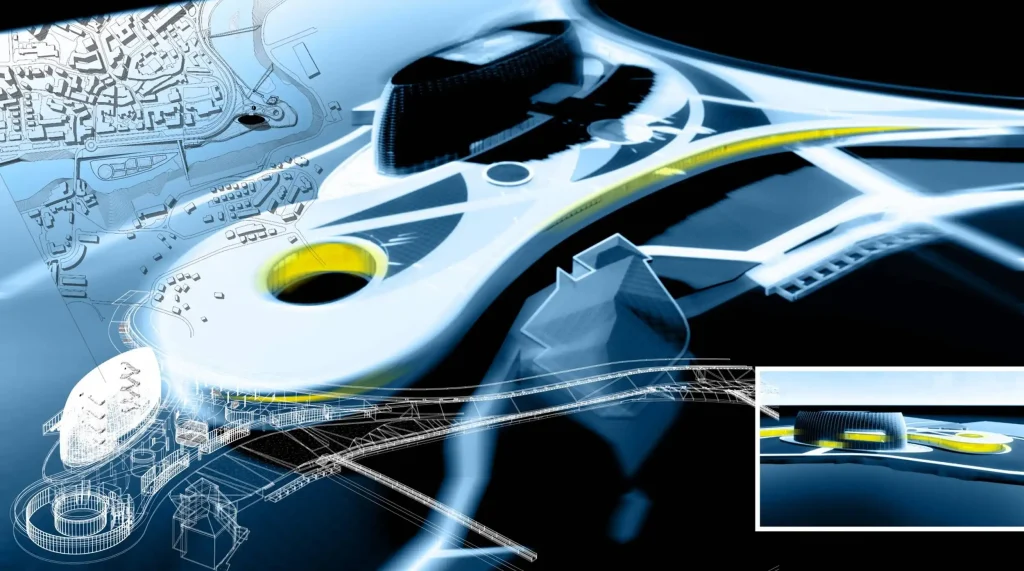

Meanwhile, BIM and 3DP work together seamlessly. Their integration goes beyond simple data exchange. It explores the procedural, organizational, and contextual aspects of these systems. By examining the intersections and correlations between these two systems, we can unlock new possibilities for streamlined project workflows, improved collaboration, and enhanced project outcomes.

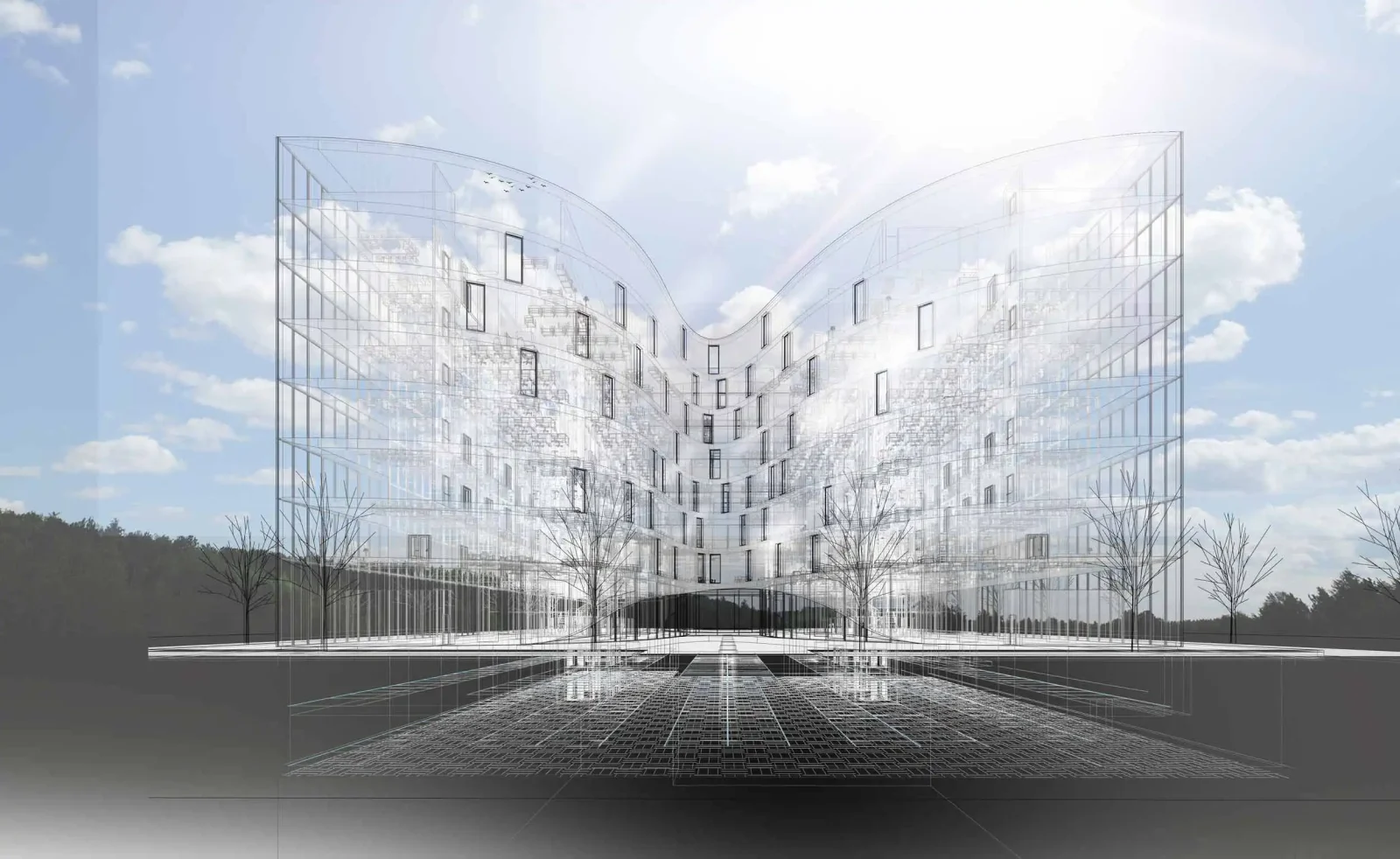

BIM and 3D printing are reshaping the landscape of construction. They enhance the way we design and plan our buildings. This connection promotes digitization through digital DNA by allowing for an all-in-one flow of data from concept to physical production. BIM software has changed architecture by boosting collaboration.

With top BIM tools, architects can visualize ideas, create automated construction drawings, and detect clashes easily. Energy analysis and other features improve workflows. This helps architects design accurately and efficiently. Embrace this technology to bring your creative visions to life. This technology is being used by startups like ICON and Apis Cor to create affordable housing units at a significantly lower cost than in the past.

Modern Construction and BIM

If we talk about the physical and functional characteristics of a building, then one must not forget BIM, an innovative method of developing and managing digital representations. BIM works as a powerful tool for architects to design, optimize, and visualize projects in 3D; it is simply revolutionizing architecture. Global emergence and adoption of digital design techniques and automated construction are making it more dominant.

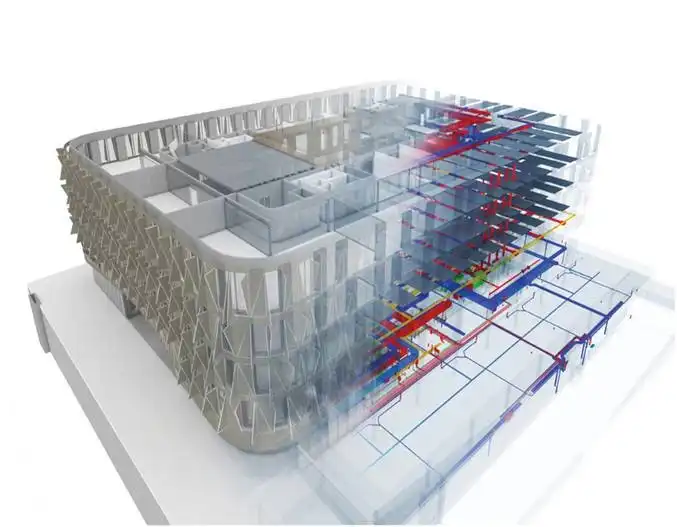

BIM does more than carve digital fingerprints; it revolutionizes project management. It champions multidisciplinary integration and steers real-time, data-driven decisions. Beyond mere 3D modeling, BIM acts as a treasure trove of information. This repository holds every detail of a building’s lifecycle, ensuring nothing goes unnoticed. Electrical and plumbing layouts, energy efficiency measuring systems, and architectural blueprints are essential components of a building’s BIM-based digital DNA.

BIM Making Connections

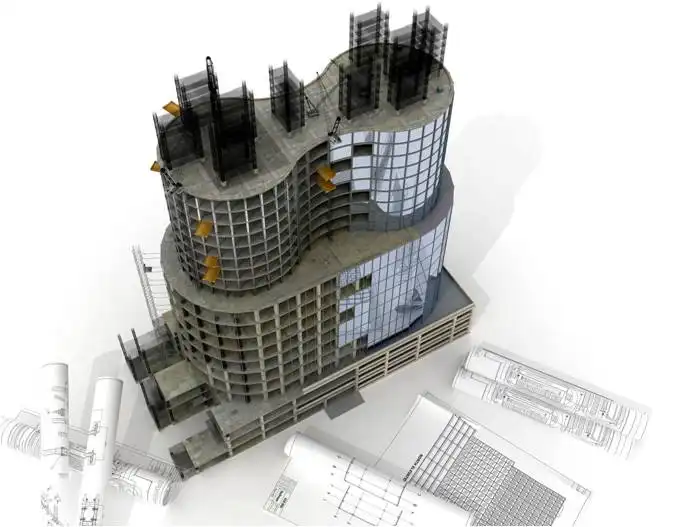

Additive manufacturing, also called 3D printing, is experiencing rapid growth. This cutting-edge technology is transforming the modern production landscape. BIM Models are driving this major transformation. With 3D printing, we turn digital designs into physical objects, building them one layer at a time. This revolutionary technology is radically reshaping the modern production landscapes, much like the Industrial Revolution did in the 18th century.

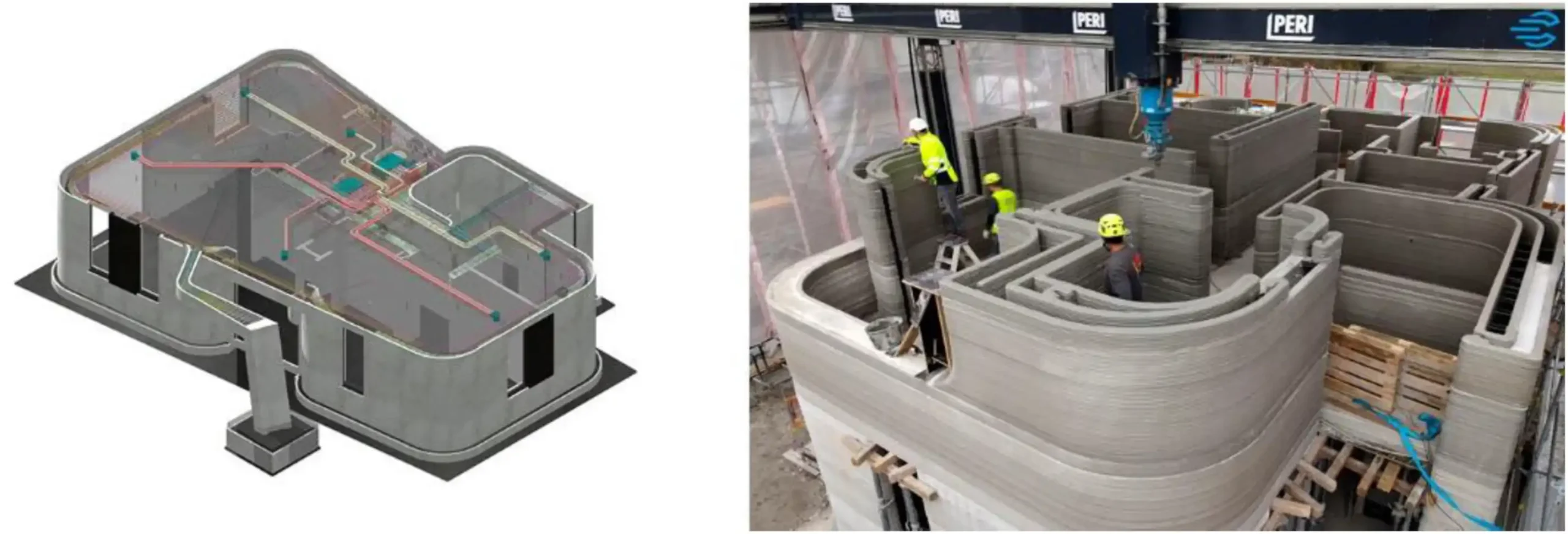

BIM models play a pivotal role here, acting as integrators and interfacing with 3D construction printing and other contemporary methodologies. The ability to generate 3D printing instructions straight from BIM models sparked developers’ curiosity. Factors influencing these models are diverse, ranging from printing timelines, analyses of joints, positioning of voids within components, and optimization of printing routes, each critically influencing the final output and even the quantity of material used in printing processes.

The Basic Workflow to Prepare Designs for Printing

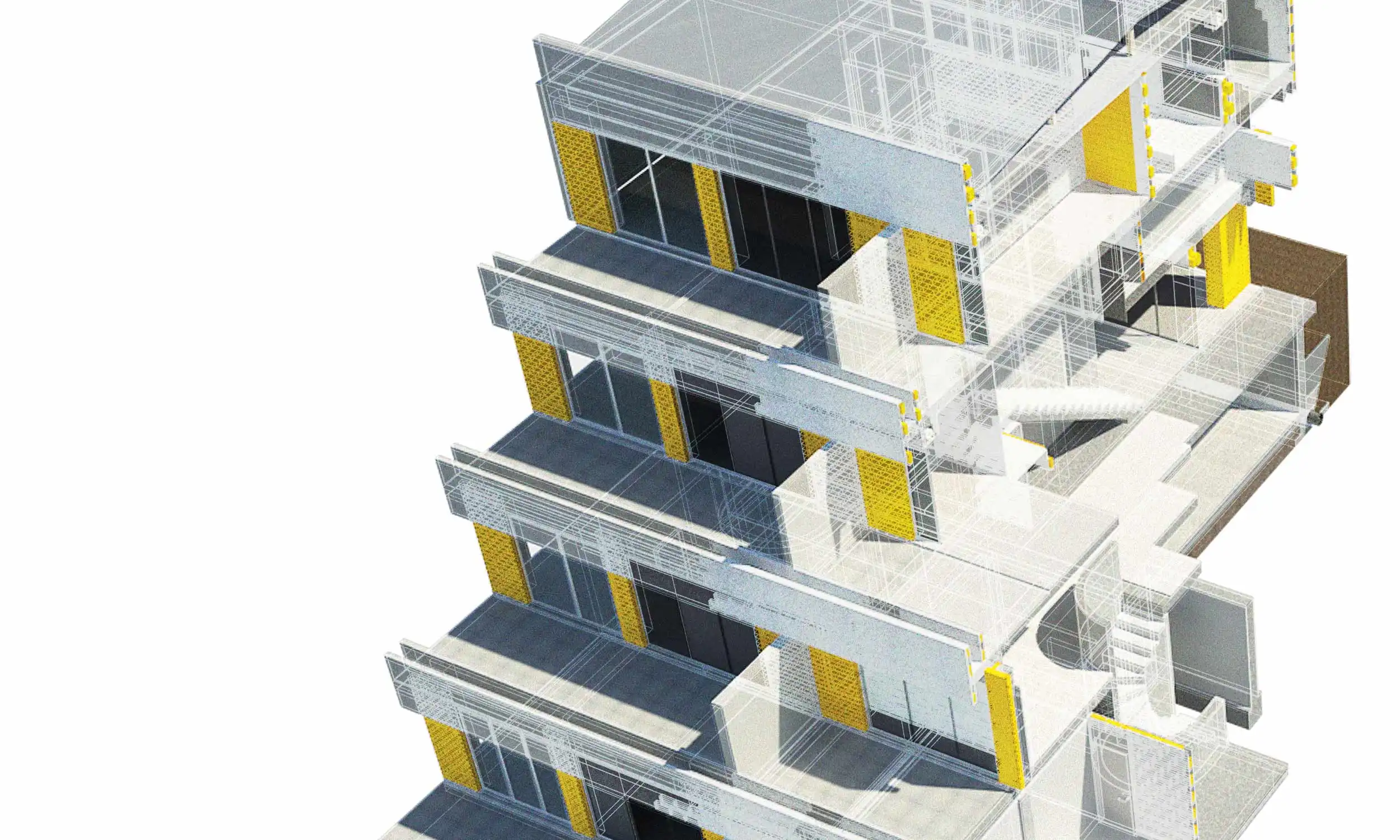

Design: BIM software, such as Revit, ArchiCAD, or Bentley Systems, is used to define the geometric shape of the building. All working details of the structure must be incorporated into the BIM model.

Data Alteration: The BIM model is then prepared for 3D printing. This involves converting the BIM data into a format compatible with 3D printing software, typically an STL or OBJ file. During this stage, any necessary adjustments are made to ensure the model is suitable for printing, such as scaling and orientation.

Slicing: The prepared model is imported into slicing software Ultimaker Cura or other, which divides the model into thin horizontal layers to produce linear contours between certain heights of structure. To create each layer of the model, the slicing software generates G-code, which is the set of instructions.

Material Selection: Appropriate printable material mixes selection with specific considerations such as the thermal properties of materials used in the mix, flexibility, and strength.

Printing: The prepared model is imported into slicing software, a digital workshop of sorts. Here, it slices the model into thin, horizontal layers, crafting linear contours at defined heights. For each layer, the software generates G-code—a precise set of instructions guiding the printing process.

Post-Processing: Once printing wraps up, the components enter the finishing touch phase. They might be cleaned, sanded, or treated to refine their appearance. After their transformation, the parts are carefully assembled following the BIM model. This meticulous alignment guarantees they blend flawlessly into the splendid design.

Quality Control and Validation: The final stage is quality control. Here, each printed component is rigorously inspected. To ensure they meet every required standard and specification. Customer satisfaction is the benchmark. The printed parts are compared against the BIM model to verify accuracy and integrity.

Perks of BIM

Efficient Alliance

BIM fosters collaboration among project stakeholders like architects, contractors, engineers, and manufacturers. With a centralized model, these teams can easily share information and refine designs. This approach helps them identify and address potential challenges early. Additionally, by integrating 3D printing, BIM allows stakeholders to create real prototypes. It gives them a better view of the final product. It also helps them understand the design details.

Faster Prototyping

One may require BIM assistance to identify design flaws in the process of prototyping. Designers can quickly create models and prototypes using BIM and 3D printing. This new way of prototyping allows them to perfect designs before manufacturing. The result is significant time and cost savings compared to traditional methods.

Customization

One of the biggest advantages of 3D printing is its ability to create one-of-a-kind parts. When designers combine BIM with 3D printing, they can make custom pieces that fit perfectly with the building’s design. This leads to a better look and better performance.

Waste Reduction

Design optimization with BIM software may lower waste and increase sustainability. Manufacturers can create accurate parts using 3D printing, which uses fewer resources and produces less waste.

Prefabrication

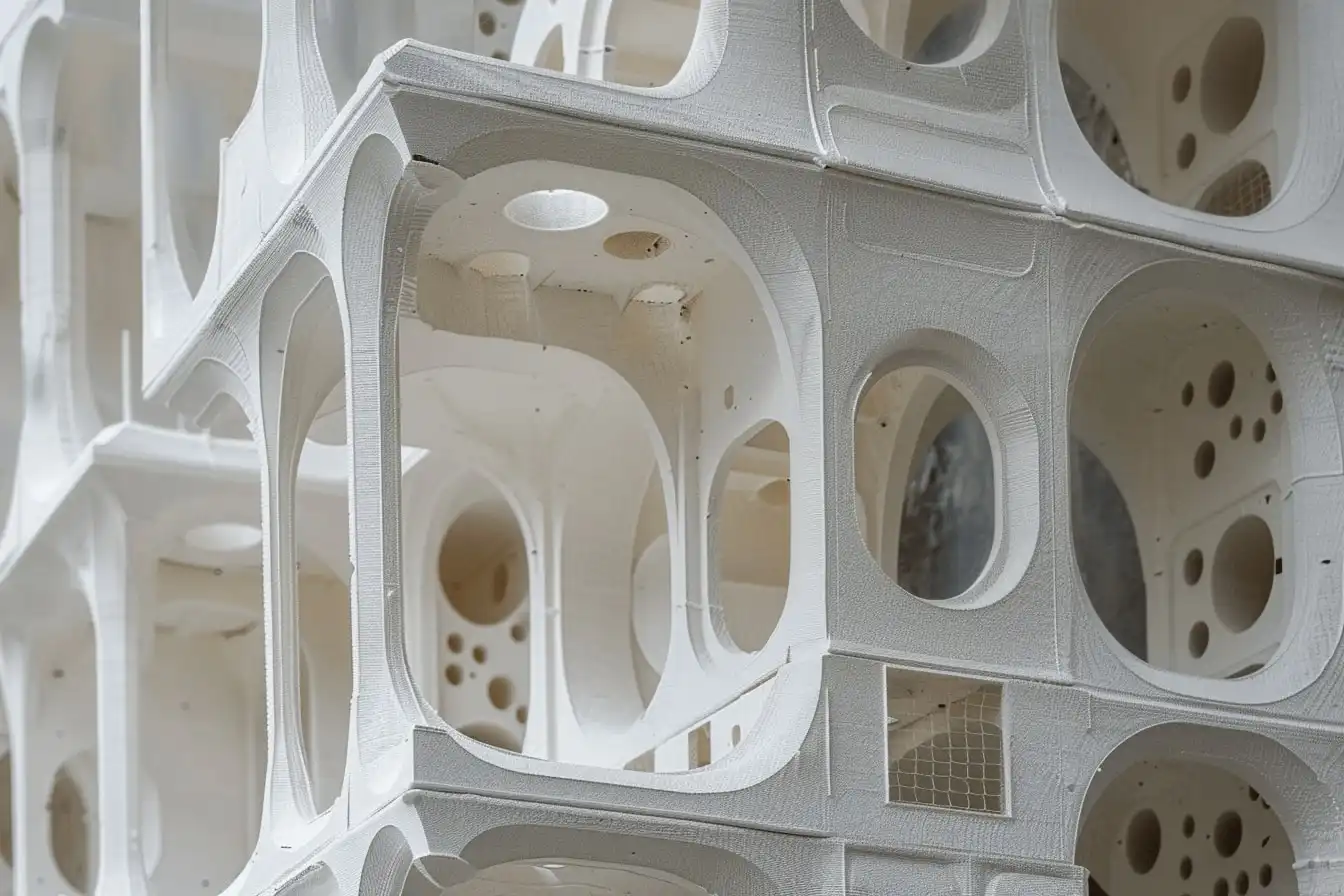

BIM models serve as the blueprints for tomorrow’s construction projects. These digital designs make way for 3D-printed components, allowing off-site prefabrication to happen easily. This innovation takes construction efficiency to a whole new level.

Structural Elements

With the use of BIM, 3D printing can quickly and accurately fabricate formwork, molds, and interim supports for complex concrete structures.

Retrofitting and Renovations

BIM models can guide the design and fabrication of customized components for retrofit projects.

Maintenance and Repairs

3D Printing can be used to create replacement parts for building systems and equipment.

Facilities Optimization

BIM data combined with 3D Printing can help optimize space utilization and improve energy efficiency.

Digital DNA acts as the foundation of current state-of-the-art structures, proving it is no longer a futuristic idea. In brief, there are many benefits of uniting BIM and 3D printing in building design, construction, and maintenance. By generating accurate drawings, encouraging collaboration, reducing waste, and improving quality control, BIM can help the construction industry make optimal use of 3D printing.

Synergistic methods of merging BIM with modern-day 3D printing bring massive growth in the construction sector. Improved visualization, quicker prototyping, and customized production are some of the perks. The future of construction will be significantly shaped and automated by the integration of BIM and 3D printing as technology keeps progressing, like generative design, AI-driven optimization, and robotics.

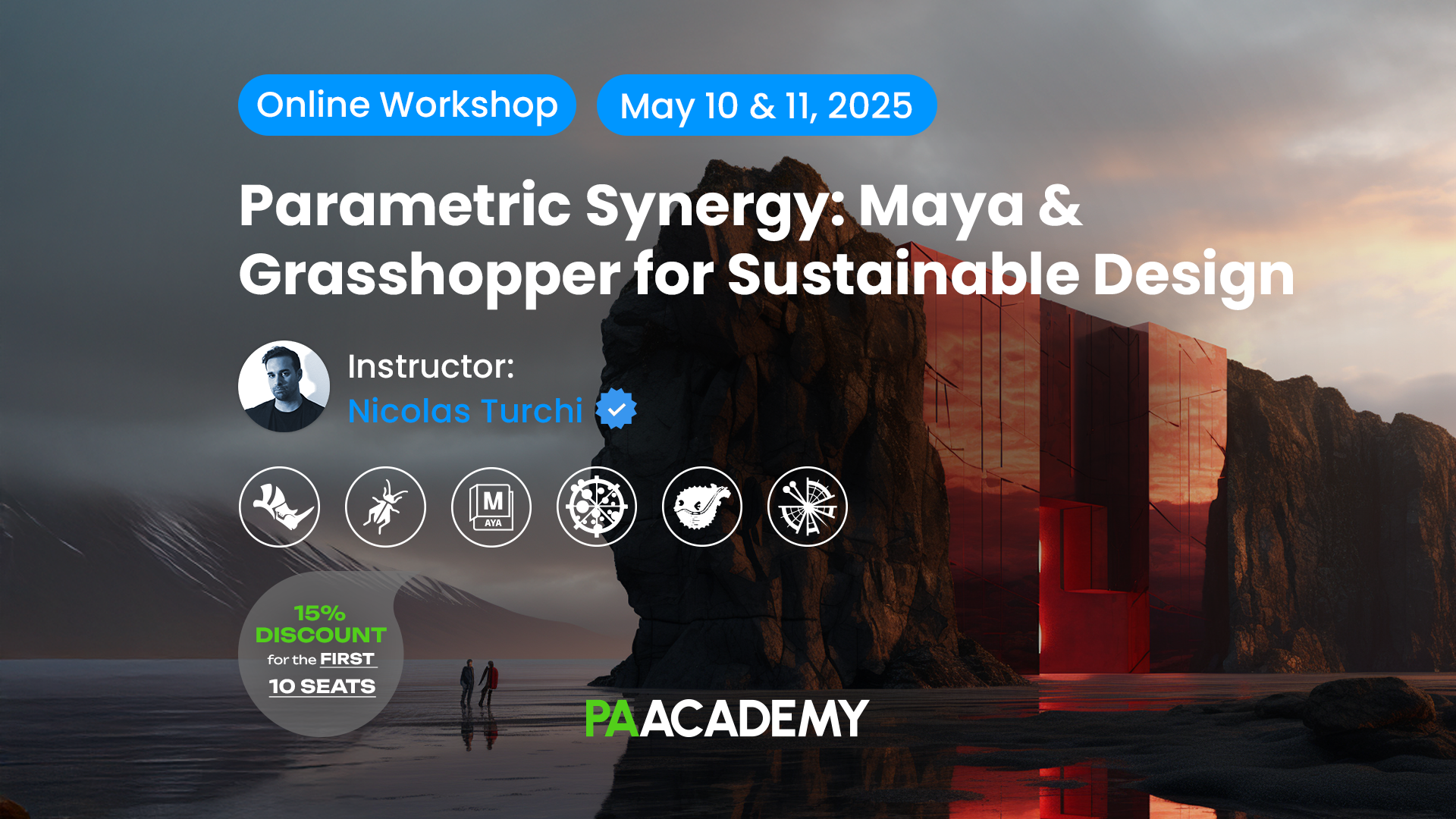

Learn with PAACADEMY: Attend workshops at PAACADEMY to learn from the industry’s best experts how to use advanced parametric design tools, AI in design workflows, and computational design in architecture!

Leave a comment