Dubai has added another architectural marvel to its growing list of record-breaking achievements, this time by reimagining interior design through additive manufacturing. Proto21 3D Printing LLC, in collaboration with MYATA Platinum Restaurant, has unveiled the world’s largest 3D-printed structure by volume, marking a historic moment for large-scale 3D printing in commercial spaces. Recognized by Guinness World Records, the structure spans 13.75 cubic meters and stands as a testament to the power of digital fabrication in redefining luxury environments.

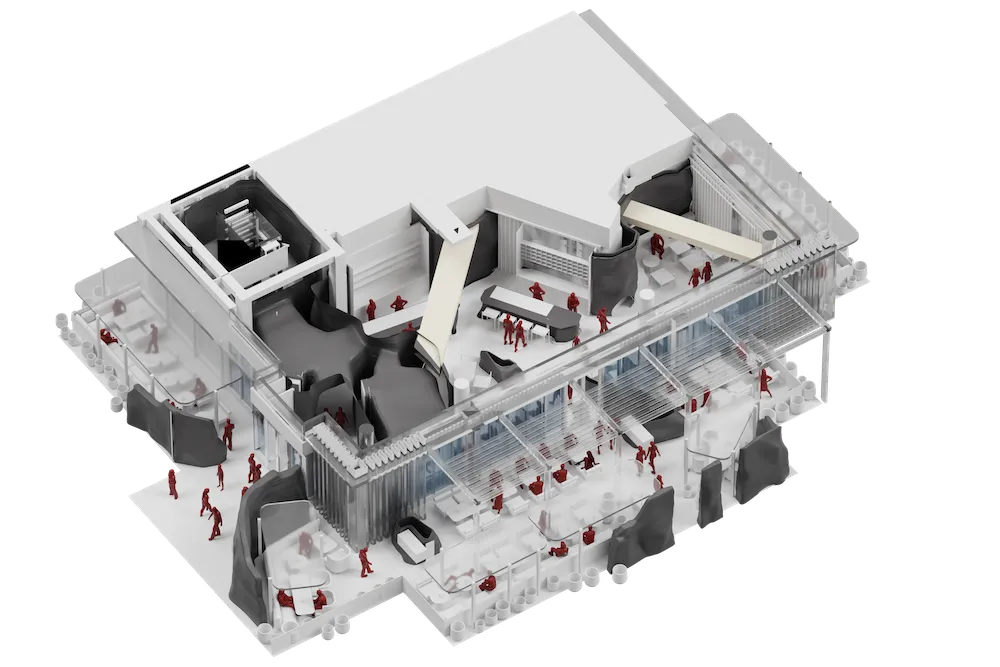

MYATA doesn’t reveal much from the outside. The entrance narrows like a funnel, leading visitors inward through a cave-like passage. Inside, the space is designed to feel like a canyon, with layered curves, textured surfaces, and soft amber lighting. The atmosphere is immersive, with light highlighting the contours of the walls. Despite its natural appearance, the entire environment is 3D printed.

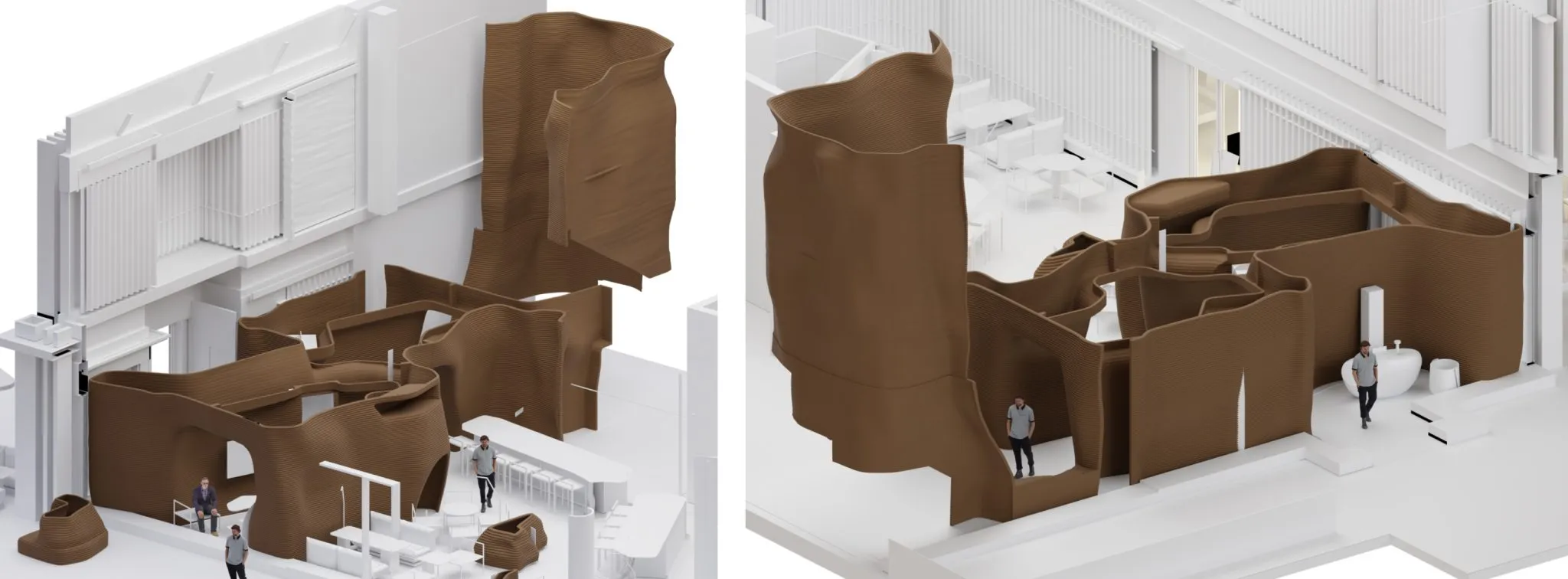

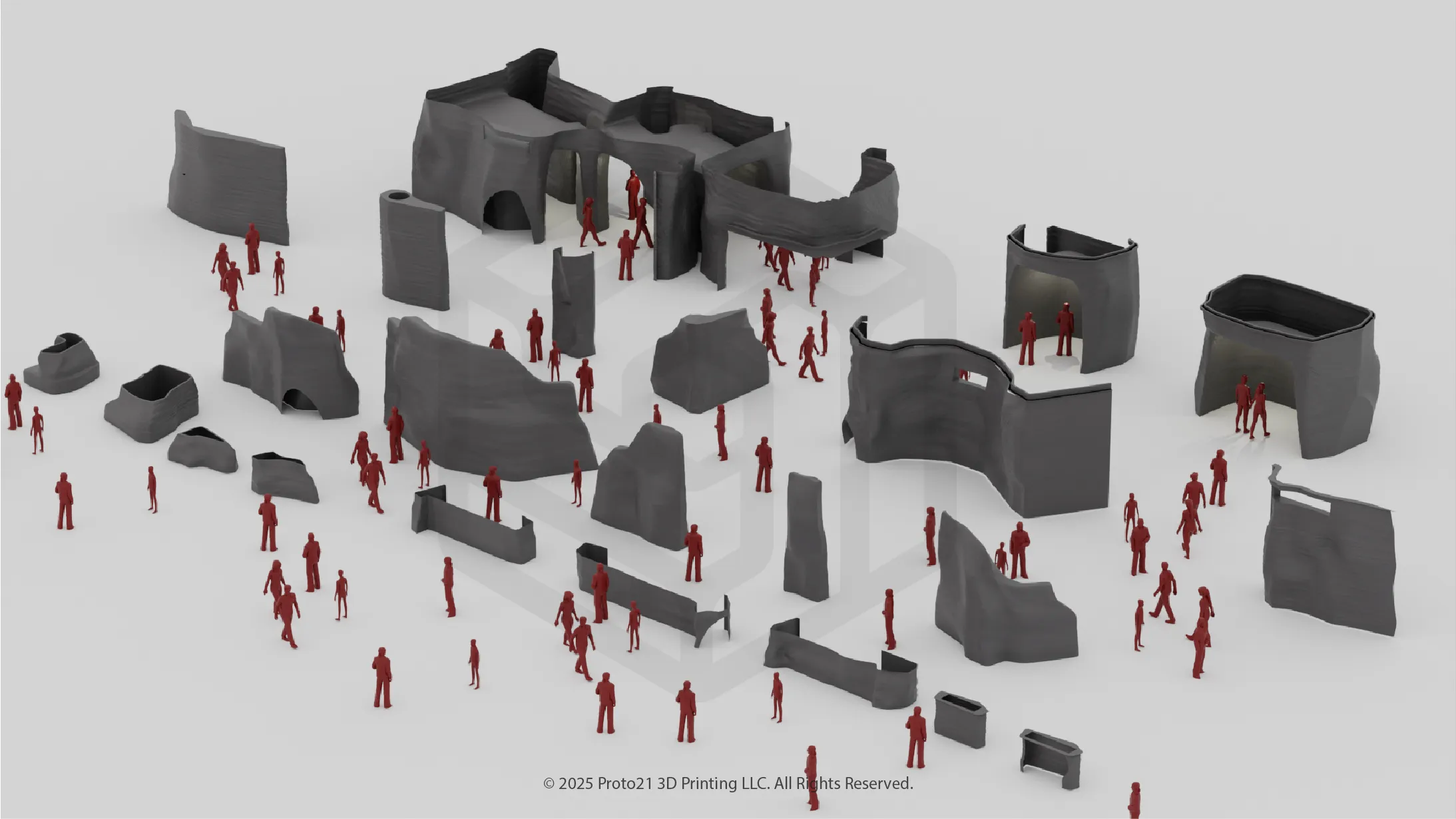

The interior spans a volume of 13.75 cubic meters, with the largest 3D printed structure incorporating an entrance area, cave, and wall facades in one continuous, sculpted form. In total, the restaurant comprises 23 large-scale printed elements, each organically shaped and entirely unique.

The digital craftsmanship behind MYATA was no less ambitious than its physical scale. Proto21’s design team sculpted each plane by hand in Blender, rejecting algorithmic repetition in favor of uniqueness, 92% of the printed components are one-offs.

Printing such a complex environment required an industrial-scale 3D printing farm with 158 machines running simultaneously. Over 21,700 individual parts were printed, consuming more than 10 tons of material and clocking upwards of 160,000 hours of total printing time. Large sections were printed using multi-axis robotic arms, bypassing traditional support structures and enabling dynamic overhangs and intricate forms.

Material selection was key. Interior pieces were printed using PLA and PETg, while external components used PPGF (Polypropylene Glass Fiber) to withstand Dubai’s intense heat. Each surface was finished with a sand-textured coating, giving the space a natural, rock-like tactility.

More Than a Milestone 3D Printed Structure

For Proto21, the project wasn’t just about scale. It was about possibility. “This is a project that redefines what’s possible with 3D printing,” says Pir Arkam, CEO and Founder of Proto21. “It’s not experimental anymore, it’s commercially viable, artistically rich, and environmentally smart.”

That last point is key. MYATA supports Dubai’s larger 3D Printing Strategy, which aims to reduce 8.8 million tons of carbon emissions by 2030 through advanced manufacturing and sustainable building practices. By minimizing waste, reducing material usage, and eliminating the constraints of traditional construction, the project stands as proof of concept for a cleaner, faster, and more creative future.

Leave a comment