All countries across the globe are investing heavily in sustainability plans for the built fabric, and the new structures come most under the radar for their green initiatives in construction and performance. Samwoh started as a construction material company in the 1970s and has since evolved into an engineering and construction business. What differentiates Samwoh from similar profiles is its investment in Research and Development of sustainable and environmental technologies and innovation. The company opened its headquarters in December of 2022, a specimen of a positive energy industrial building, the first in Singapore.

Designed by Enari Architects with AC Consortium Pte Ltd as the Architect of Record, the building was awarded the Building and Construction Authority’s (BCA) Green Mark Platinum Positive Energy certification for its ability to produce more energy than it consumes. The final design decisions; from elevating the entrance to the second level through a landscaped ramp to provide views of green spaces at arrival, incorporating real-time monitoring systems to optimise energy consumption, placing creepers on the east and west facades to reduce heat gain, planning landscaped decks and courts to create green punctures, employing the roofs to house the solar panels for energy production, to the designing of an open space office concept that brings in natural light and facilitates gathering; are all conscious efforts to supplement the company’s sustainability and innovation goals.

What special features make Samwoh Smart Hub sustainable?

The site comprises four segments – the office building, the asphalt production plant and bunkerage, the processing facilities building, and the safety training centre-cum-workshop building. The site is located along the heavily industrialised area of the north coastline of Singapore, an area focusing on revitalising the seashore before making it available for public access. The Samwoh’s buildings embrace this vision and concentrate their design efforts to create a holistic and sustainable working environment.

Building Materials:

All the materials used in the construction of the building were recycled, repurposed, or green. The building used repurposed sedimentary rocks as structural concrete from the Jurong Rock Caverns, a nearby underground cavern that is used as a storage facility, instead of using imported granite. The building is using itself as a litmus test for assessing the strength of sedimentary rocks in construction, and its potential to replace granite as a safe alternative. Under observation through embedded fibre optic sensors, the building has been deemed structurally safe thus far. Another material that the structure used after prior experimentation is the recycled concrete aggregates, which facilitated full recycling of demolition waste, reduced cost, and reduced carbon footprint. Other building materials include green cement and Manufactured sand (M-sand).

Design Elements

With sustainability at the core of everything Samwoh does, the main aim of the project brief was to reduce energy consumption and to use renewable sources to power the building. Designing according to the site condition, the office spaces were oriented in the north-south direction. This allowed the opening of the built structure towards the natural surroundings or landscaped spaces like internal courtyards using glazing for both views and natural daylight. The east and west walls were heavily thickened with double skins, fins, and plantations to protect the indoor environment from the harsh heat, and noise and smell from the surrounding industrial facilities.

Energy Efficient Systems

The various AI-driven smart energy management systems help to optimise the performance of the structure to make the building very efficient. Using an ecosystem of connected smart devices, software, apps, and services helps to seamlessly collect, analyse, and adjust data to make the structure efficient and healthy.

Power meters, wireless sensors, circuit breakers, and other smart systems help to accurately measure energy consumption in real-time, which can be accessed globally, recorded, and used to optimise the temperature and humidity of the indoor environment based on occupancy, making it comfortable and more efficient. The system also includes cloud-based analytics and a centralised dashboard that merges energy and utility data, gives a consolidated view across individual technological systems, helps to understand and enhance user experience, and alerts to any power or equipment abnormalities that could potentially prevent failures. This has enabled the building to lower its utility bills by about 50% while enhancing its performance.

Positive Energy Building

The main power source for the building is the 2,588 solar panels atop the workshop and processing facilities, which produce at least 25% more electricity than needed by the structure. This extra electricity is sent back to the national grid. This is possible because of how efficiently the structure is constructed and how the sustainability systems perform to optimise energy consumption. The building currently uses less than 60 kWh of energy per square meter yearly.

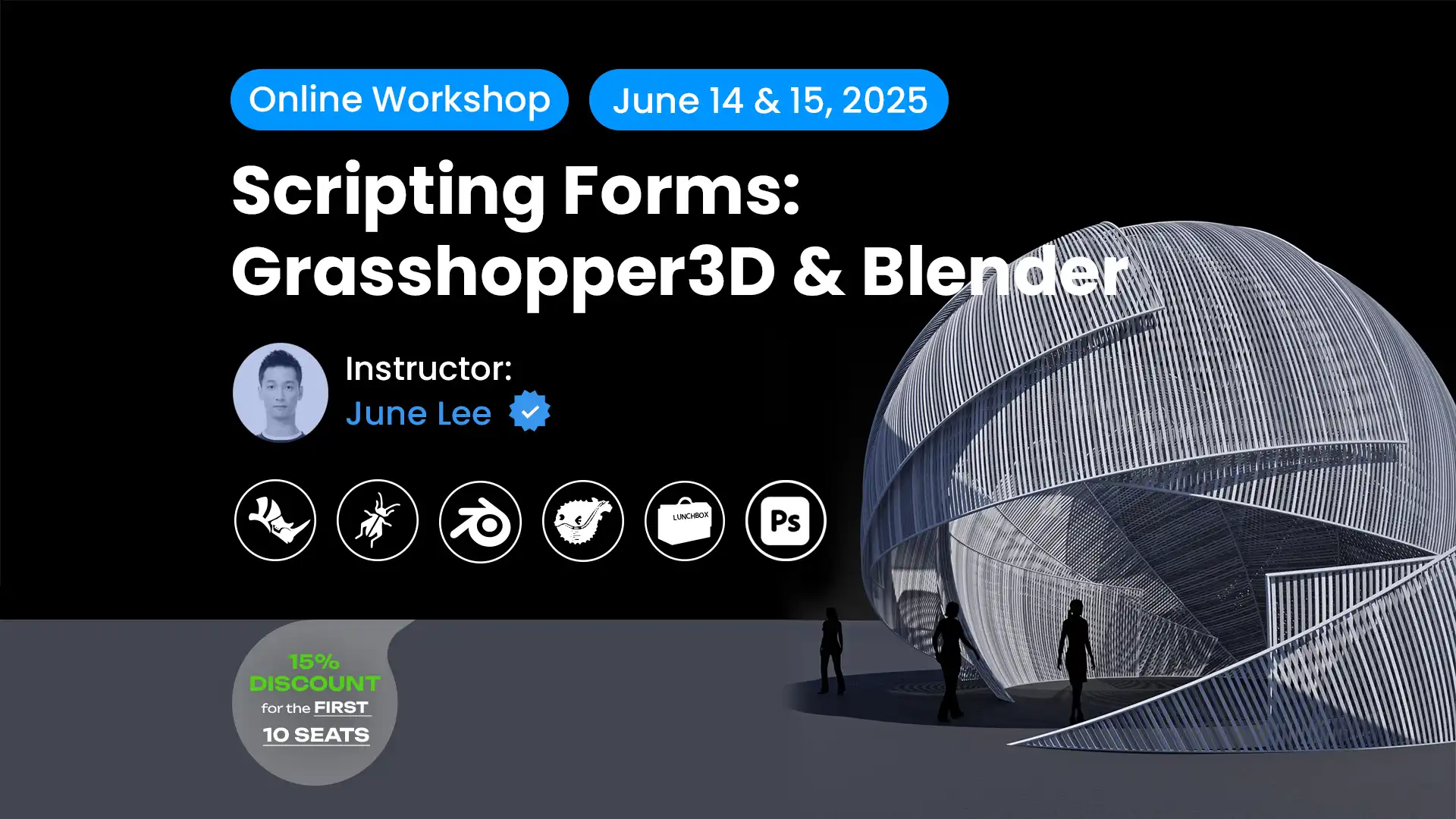

There are various tools that can be used to facilitate how systems can function in real-time during the design process itself. These can help to create energy-efficient structures and even positive energy structures like the Samwoh Smart Hub. To know how to employ these tools, check out the courses offered in PAACADEMY, which could empower you to create truly sustainable structures.

Outcomes of Employing Sustainable Systems at Samwoh

- The roofs of the buildings on the site accommodate 2588 solar panels that can monthly generate enough energy to power 300 four-room apartments in a month potentially.

- The built structure uses only 60 kWh of excess energy per square meter yearly. This allows about 25% of the generated energy to be returned to the national grid.

- The energy-efficient systems and optimisation of on-site renewable sources have helped to decarbonise and attain a 50% reduction in annual utility bills.

- The building is a testament to using sedimentary rocks as a safe alternative to granite, fostering the use of repurposed materials in construction.

- The use of recycled cement aggregates has helped to reduce the cost and use of demolition waste, enabling a decrease in carbon footprint.

- All these steps help to lessen operational carbon emissions by about 845 tonnes per year.

- The asphalt plant on the site is 15% more energy efficient than a conventional plant, which is projected to achieve a carbon abatement of 1220 tonnes per year. This is equal to removing 265 cars from the roads yearly.

Sustainability extends beyond just the built structure at Samwoh

The concept and initiatives incorporated into the structure of the Samwoh Smart Hub were just an extension of what the company believes and represents. The company already had a head start on its green journey through its innovative products and interventions in the construction industry. This includes developing and successfully incorporating many first-of-its-kind products like low-carbon asphalt pavements, eco-green concrete, and waste-water treatment technology, with many more sustainable innovations in the pipeline.

This building is a paradigm of how partnerships, planning, and technology can be leveraged to create designs that showcase progress and stewardship towards achieving sustainability goals. The headquarters was designed not only to be an example of Samwoh walking the talk but also to provide an environment to breed talent, where productivity thrives in healthy, well-designed spaces. Where the choice to lead a more sustainable life in the workplace permeates into the employees and flows into their personal lives too.

Leave a comment