At the 2024 Venice Biennale, a fascinating innovation in architectural design and digital fabrication garnered significant attention. Featured within the European Cultural Centre’s ‘Personal Structures’ exhibition, the DIAMANTI Canopy is a visionary project that exemplifies the future of sustainability and computational design in architecture.

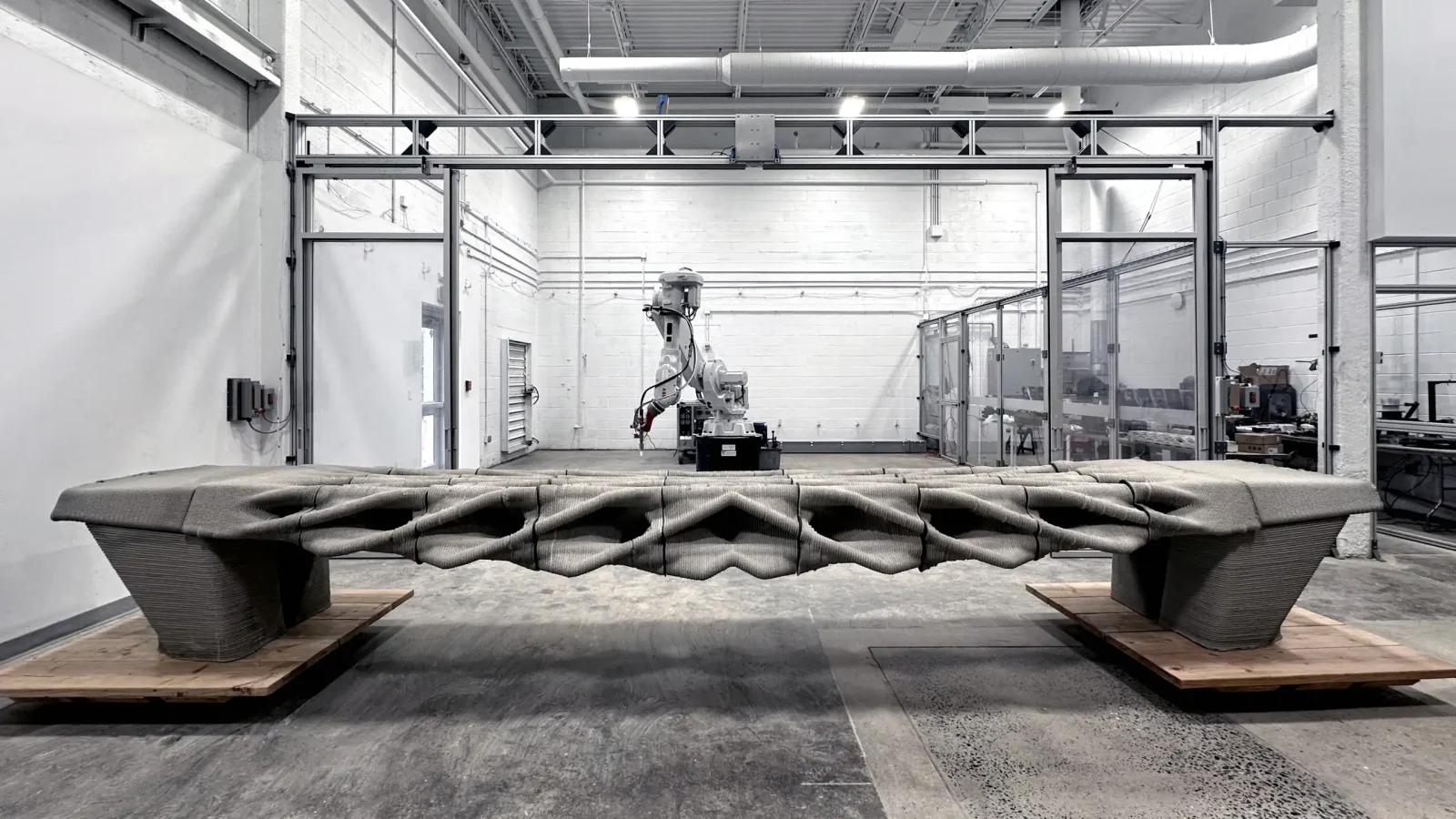

Crafted through an intense collaboration between academia and industry, this ten-meter-long canopy is unique in its structure. It effectively combines lightweight engineering with sustainable ambition. A next-generation marvel, designed using 3D concrete printing (3DCP) and held together with post-tensioning, the project is a statement for modern architecture. It shows its viewers how modern construction can be both environmentally sustainable and structurally radical to stand as an epitome of world-class architecture.

Can a Concrete Canopy Be Both Lightweight and Sustainable?

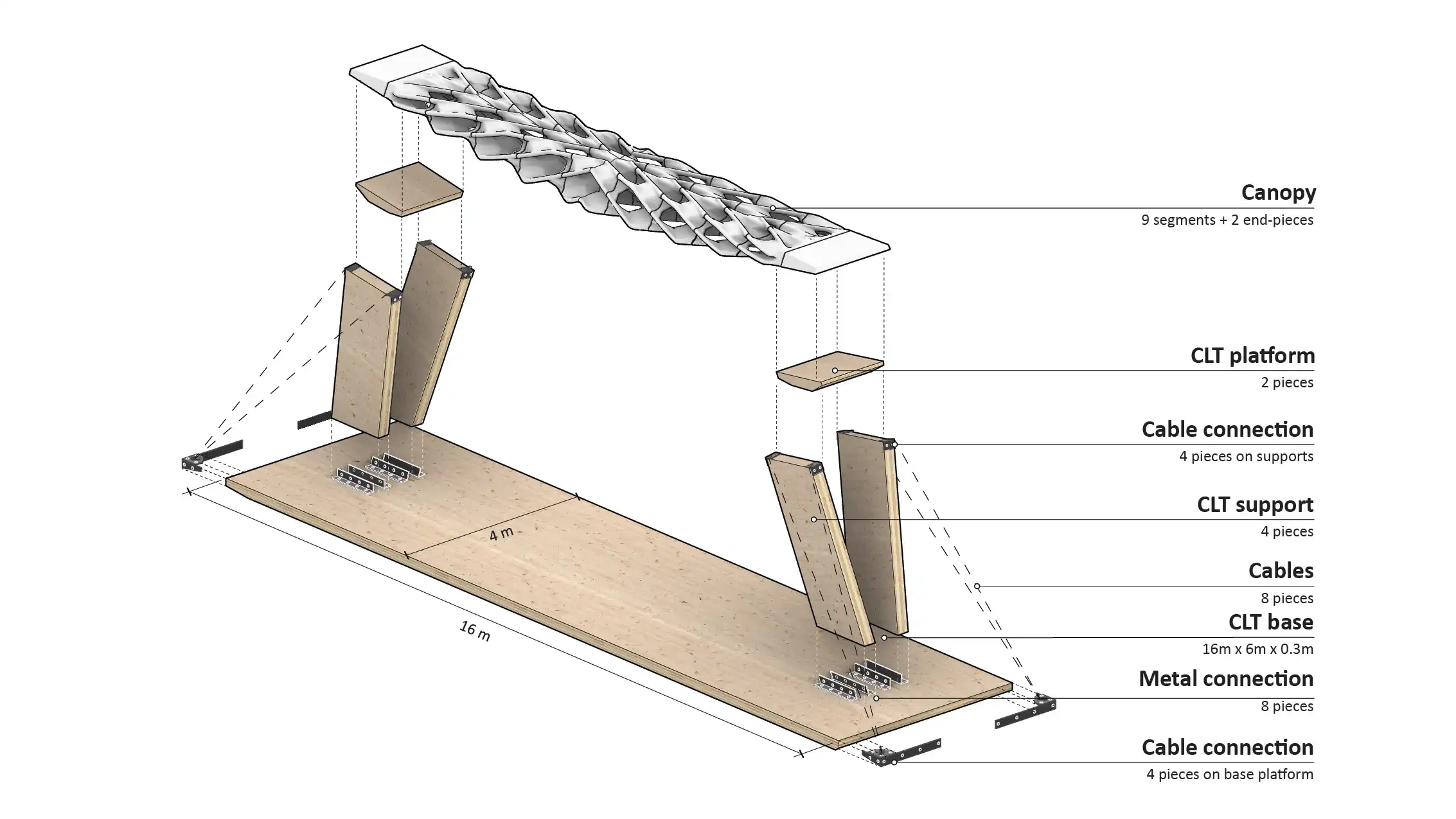

Supported not by traditional concrete foundations but by a cross-laminated timber (CLT) platform, the DIAMANTI Canopy serves as an unparalleled disruptor to the typical supposed material hierarchy. Instead of timber spanning across concrete, the roles are reversed to deliver a project of architectural brilliance. This deliberation emphasizes lightweight design, with timber acting as the foundation and concrete as the elevated surface.

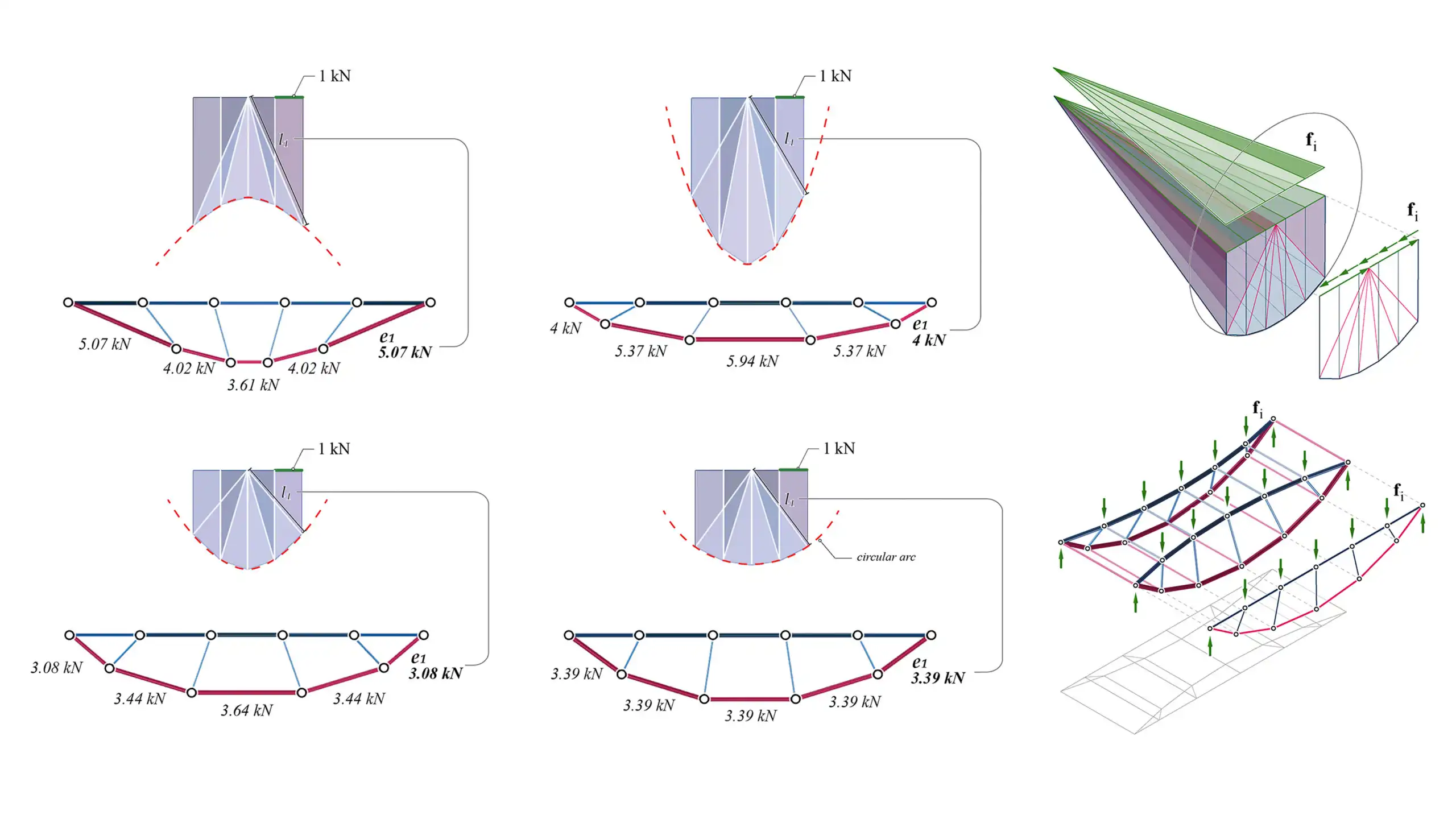

By combining materials in such a calculated way, the canopy reduces embodied carbon, reducing carbon emissions in the process. While maximizing strength, its geometry is also based on a diamond-shaped triply periodic minimal surface (TPMS), which essentially distributes both compression and tension forces efficiently, using both as fundamental to its high stability and utility.

A Multi-Team Collaboration Built on Innovation

Behind the canopy is a plethora of hard-working contributors led by the Polyhedral Structures Laboratory at the University of Pennsylvania. With input from researchers at the City College of New York and Villanova University, along with support from Sika Group and post-tensioning experts at Amsysco, the project comes out not only truly global in scope but also sets a precedent for the future of architecture.

From material calibration to full-scale 3D printing and tensioning, each partner brought a unique strength to the table.

The result? A modular, recyclable installation that demonstrates what’s possible when computation, fabrication, and material science converge to create a brilliant structure.

Why the DIAMANTI Canopy Matters

Rather than the contemporary pouring of concrete into formwork and reinforcing it with steel, the design uses geometry as structure. Post-tensioned cables travel through pre-designed voids within the 3D-printed body, forming a taut, efficient canopy.

The outcome is an architectural prototype that’s lighter, faster to assemble, and significantly less wasteful than conventional construction.

Computational design is making advances from algorithmic design to machine learning capabilities powered by large datasets, enabling designs previously unimaginable.

Building a New Structural Language

Essentially, the DIAMANTI Canopy encourages a new approach to technology development. Its designers chose to shape the design based on the forces of tension and compression, which influenced the curves of the structure.

If we want to address the major environmental and urban challenges of our century, more architects and engineers should adopt this thinking.

The sculptural form and strict engineering of the DIAMANTI Canopy give us a look at what’s awaiting us in architecture. DIAMANTI demonstrates from Giardini della Marinaressa to the design community that construction in the future will be lighter, more efficient, and more sustainable.

DIAMANTI Canopy Project Details

Architect/Lead Designer: Masoud Akbarzadeh and the Polyhedral Structures Laboratory, University of Pennsylvania

Client: European Cultural Centre

Completion: 2024

Location: Giardini della Marinaressa, Venice, Italy

Leave a comment