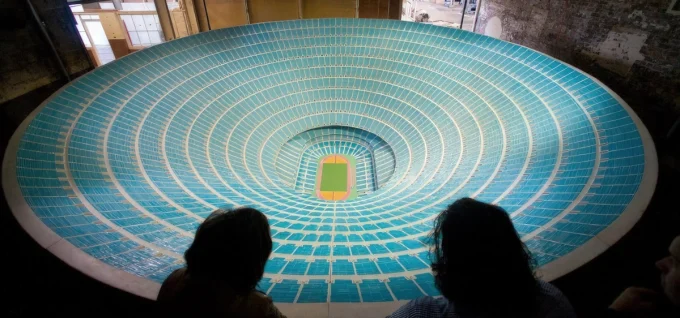

As part of the INTERNI “Cre-Action” exhibition at the Università degli Studi di Milano, Aevum emerges as a collaboration between Zaha Hadid Architects (ZHA) and architectural 3D-printing specialists Vertico. The 6×6-metre installation juxtaposes two arches, one crafted from solid marble, the other produced using large-scale 3D printed concrete, offering a physical dialogue between traditional craftsmanship and contemporary construction technologies.

Installed within the university’s historic courtyard, Aevum references the architectural heritage of its surroundings while introducing new possibilities for material use and fabrication methods. The marble arch reflects timeless artisanal methods, while the adjacent concrete arch, printed by Vertico, embodies the speed, flexibility, and formal freedom enabled by robotic additive manufacturing.

The project was delivered in a remarkably short timeframe, with Vertico taking just two weeks from receiving the CAD model to completing production. The installation process itself was condensed into a 7-day window, supported by the efforts of Carpenterie Pezzetti and Eckersley O’Callaghan. Vertico’s proprietary Accelerator printhead and a custom 2K Sika cement mix enabled the creation of overhangs and non-planar geometries, an essential feature in executing ZHA’s spatially complex vision.

Aevum also serves as a platform for material experimentation. As part of ZHA’s ongoing research into sustainable construction, the 3D-printed arch incorporates marble dust waste, reclaiming stone industry by-products and testing their integration into printable cement-based composites.

By optimizing structural geometry and reducing material use, the installation highlights the ecological potential of additive manufacturing, demonstrating how design, engineering, and sustainability can converge. It serves as a model for circular thinking, using digital tools to create expressive and efficient forms. More than a display of technical skill, Aevum quietly prompts us to consider where architecture is going, and how the old and new might shape it together.

Aevum Installation Details:

Location: Milan, Italy

Architecture Firm: Vertico, Zaha Hadid Architects

Structure: Eckersley O’Callaghan

Height: 5.6 meters

Number of Elements: 21 unique printed parts

Weight: 5.5 tons

Print Time: 48 hours over 6 days

Software Used: Rhinoceros3D, Grasshopper3D

Leave a comment