At Expo Osaka 2025, Aki Hamada Architects (AHA) developed a one-of-a-kind 3D-printed earthen rest facility that employed a stand-alone crane by WASP. The AHA suggested a vision for future architecture in which people construct their own nests from locally sourced materials.

Soil was chosen as the material because it is a readily available and locally sourced resource that can be replenished in the ground. This project demonstrates a future in which humans, nature, and robots cohabitate, as achieved through natural-material architecture and advanced robotic 3D printing.

The structure was erected utilizing a Stand-Alone Crane WASP from WASP, capable of extruding earth to create a canyon-like architectural and landscape installation, as well as materials supplied entirely within Japan. The printed mixture, which was modeled after the traditional earthen walls of Japan, contained earth, clay, straw, pigments, hardening agents, and seaweed glue.

The structure’s shapes are derived from organic curves that were gathered using 3D scanning from different parts of Japan. The building’s earthen components include a number of benches, planters, and basins for hand washing.

3D-Printed Bench Planters

The crane 3D printer worked on-site, fabricating planters that serve as benches and tables. Four sets of these installations were created using the 3D printer’s full build capacity (6.2 meters in diameter and 1.7 meters in height) and placed throughout the site. The planters took various forms, such as C-shapes that surround visitors or many clustered “islands”. This is made to create rest areas that encourage various ways of utilization for visitors.

3D-Printed Wall Blocks

Wall blocks were printed by using natural earth as the main component. The outer panels of the structure were prefabricated in a Toyama facility using the Crane WASP. A total of 56 modules were printed, measuring 0.93 meters wide, 0.3/0.4 meters deep, and 1.2 meters high. Once printed wall blocks were cured, they were transported and placed on-site, covering the distance of approximately 112-124 miles.

Each block had a unique surface, and together they created a texture like actual rock. Given the scale of panel printing and transport was unparalleled, the entire process, from fabrication to installation, was planned from scratch.

3D-Printed Hand Wash Basin

The wash basins for toilet users were also 3D-printed in the factory and brought to the site. These cylindrical pieces had a recessed front for knee room and a maintenance aperture at the back, allowing them to be slid beneath pre-installed sinks and countertops.

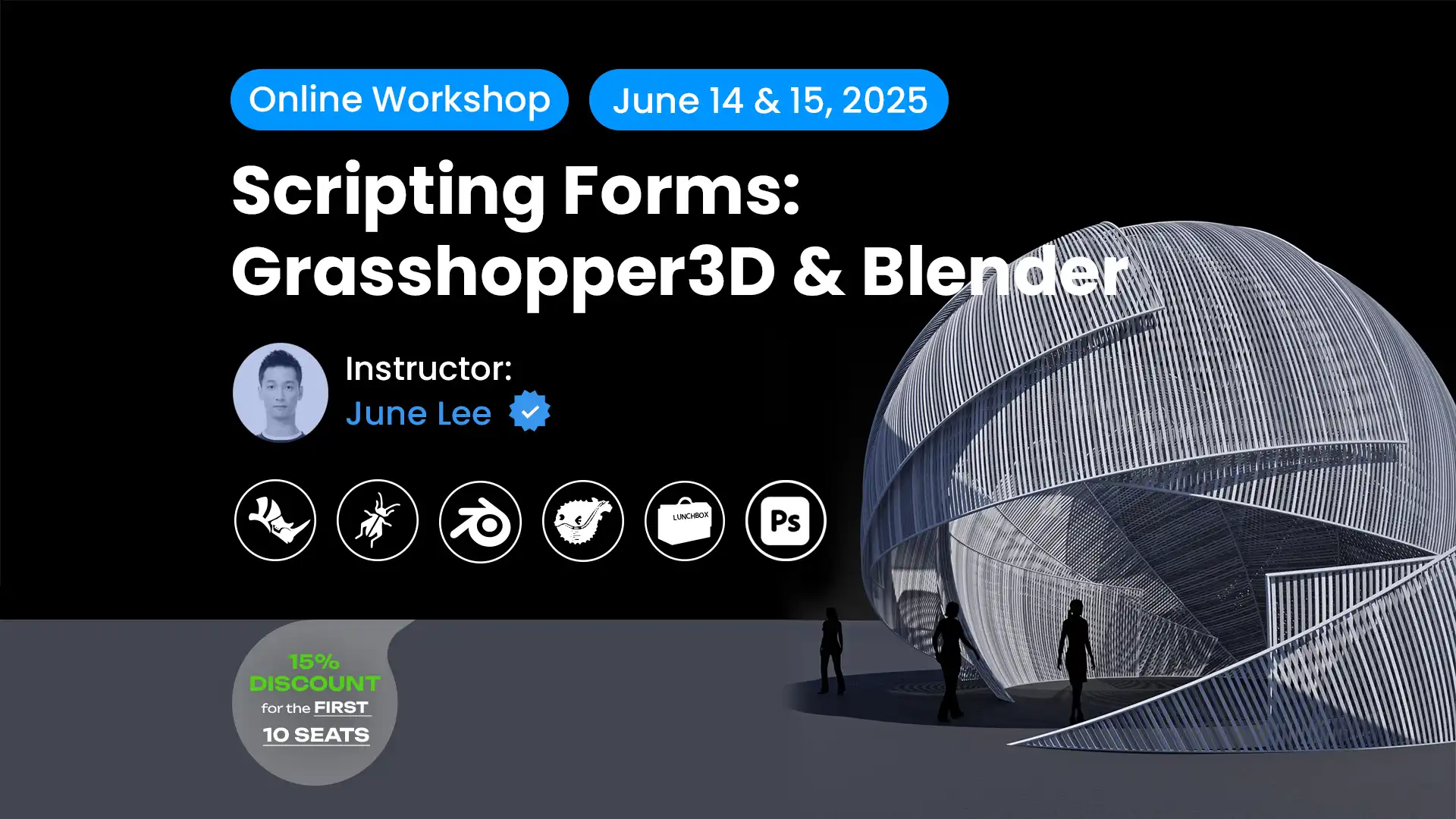

Interested in mastering similar techniques? Explore the 3D Printing Clay Mastery workshop at PAACADEMY to learn advanced clay printing methods using Rhino and Grasshopper, with a focus on optimized, material-aware toolpath design

3D Printed Earthen Rest Facility Project Details

Exhibition: Expo 2025

Location: Osaka, Japan

Architect: Aki Hamada Architects (AHA)

Technology Used: Stand Alone Crane WASP

Leave a comment